4 Tier Layer Cages for 25,000 Birds Automatic Layer Poultry Farm in Ghana

Project Overview

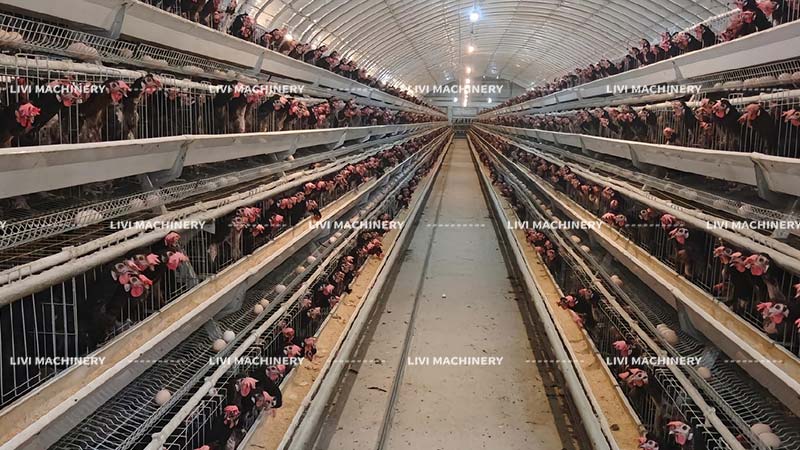

In 2025, Livi Machinery successfully delivered a full set of 4 Tier Layer Cages and automatic poultry equipment for a large-scale egg production farm in Kumasi, Ghana. The farm, designed to raise 25,000 laying hens, adopted full automation to enhance productivity, reduce labor costs, and improve overall farm hygiene. This project marks a major step forward in the modernization of Ghana’s poultry industry.

Client Goals and Tailored Solution

The client required:

- Housing for 25,000 laying hens in an efficient and hygienic environment

- Full automation of feeding, manure removal, and egg collection

- Durable equipment resistant to corrosion in humid conditions

- Reduced manual labor and improved daily operation

After a detailed assessment, Livi Machinery recommended a 4 Tier Layer Cages system configured in 3 rows, with approximately 8,333 birds per row. To support full automation, the following equipment was provided:

- 1 gantry-type automatic feeding machine for the entire house

- 3 belt-type manure cleaning machines (1 per row)

- 3 egg collecting machines (1 per row)

- Complete nipple drinking system with filters, regulators, and medication dosing units

This system provided an efficient, labor-saving, and hygienic production environment suited to large-scale egg farming.

Farm Layout and Equipment Supplied

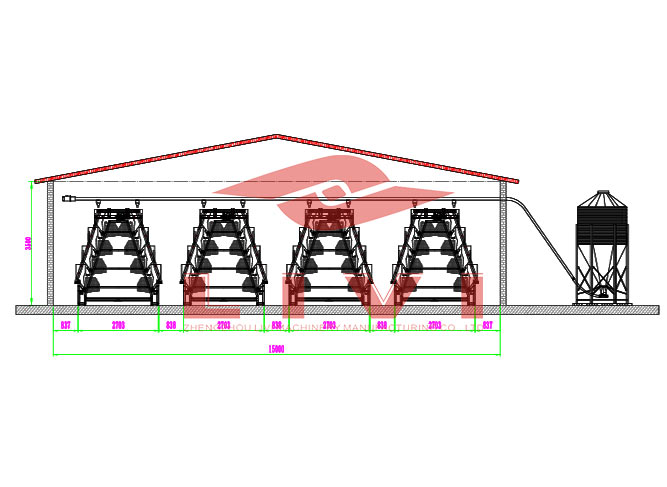

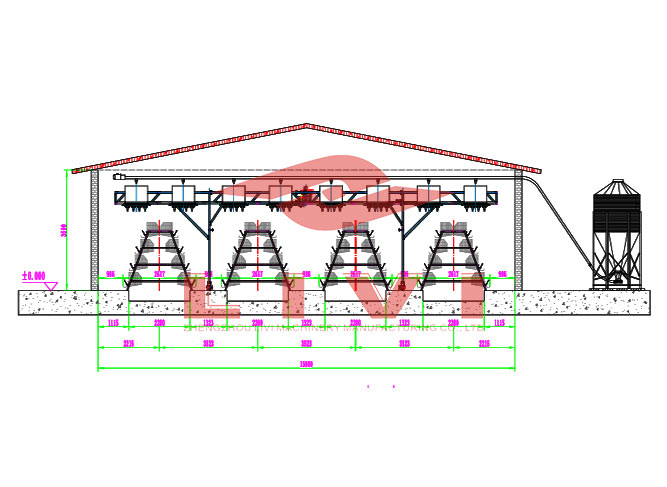

The poultry house was constructed following Livi’s optimal design, with 3 rows × 4 tiers of layers cages. The structure was built with adequate ventilation openings and ridge vents to ensure healthy airflow for the birds.

Delivered Equipment Includes:

- 126 sets of 4 Tier Layer Cages (hot-dip galvanized, anti-rust)

- 1 automatic gantry feeding machine

- 3 belt manure removal machines (one for each row)

- 3 egg collection machines (one per row)

- Drinking system with mainline tank, pressure regulators, and dosing medicator

- Installation manuals, layout drawings, and a complete spare parts package

Installation and Support

Livi provided:

- Complete civil construction guidance and poultry house layout drawings

- Remote installation instruction videos and technical consultation

- On-site training (through local partners) for daily equipment operation and maintenance

The farm team successfully installed the system within 4 weeks and transitioned into full operation shortly after.

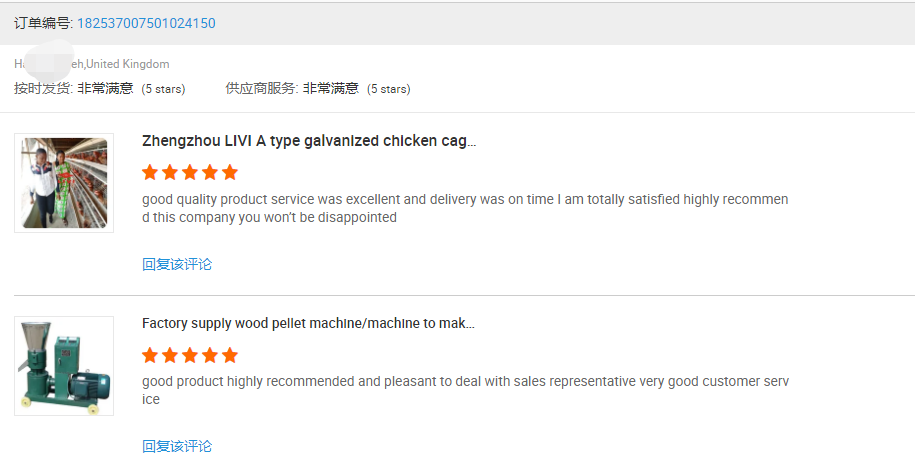

Client Feedback

Shortly after production started, the client reported:

- A significant increase in daily egg production and egg cleanliness

- Labor savings of over 50%, especially in feeding and manure handling

- Smooth and efficient egg collection with minimal breakage

- Consistent and hygienic house conditions thanks to the belt-type manure cleaning system

The client praised the structural quality and ease of operation of the 4 Tier Layer Cages, and is already planning a second phase of expansion.

Why Choose Livi’s 4 Tier Layer Cages?

Livi Machinery’s 4 Tier Layer Cages are ideal for medium to large-scale egg farms aiming to modernize their operations. Benefits include:

- High bird density in limited space

- Full compatibility with automated feeding, cleaning, and egg collection

- Long-lasting galvanized steel material

- Expert farm layout planning and global technical support

From planning to delivery and installation, Livi offers complete solutions to help farmers achieve success.