4-Tier Layers Cages for 30,000 Automatic Chicken Farm in Rwanda

Project Overview

In May 2020, Livi Machinery successfully delivered and supported the installation of a fully automated layer cage system using 4-Tier Layers Cages for a large commercial poultry farm in Rwanda. Located near Kigali, this modern farm was designed to house 30,000 laying hens, making it one of the region’s most efficient and advanced egg production facilities. The client chose Livi for our ability to provide high-capacity, automated solutions with robust performance and long service life.

Client Requirements and Our Customized Solution

The client’s primary goals included:

- Housing 30,000 layers in a modern and compact structure

- Full automation of feeding, egg collection, and manure cleaning

- Strong, rust-resistant cages built for Rwandan climate conditions

- Reducing daily labor while improving operational efficiency

After comprehensive farm design consultation, Livi Machinery recommended the 4-Tier Layers Cages system combined with:

- Automatic gantry-type feeding machines

- Belt-driven manure removal system for hygiene and odor control

- Egg collection conveyors with gentle transport mechanism

- Nipple drinking lines with filters and pressure regulators

- Environmental ventilation support system

This fully automated setup ensures continuous egg production, minimal waste, and optimal bird welfare.

Farm Layout and Supplied Equipment

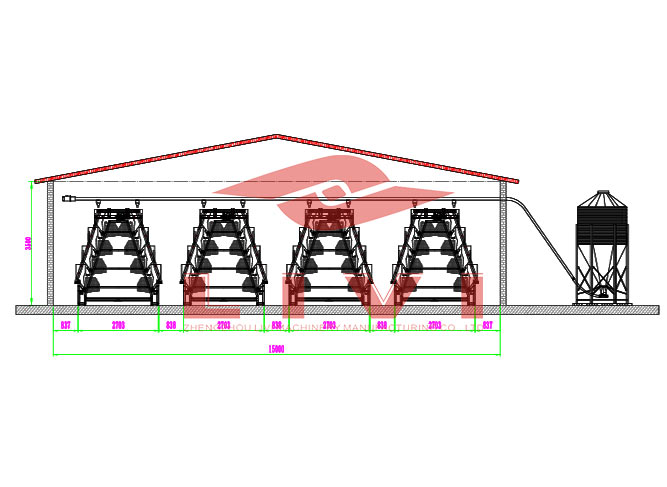

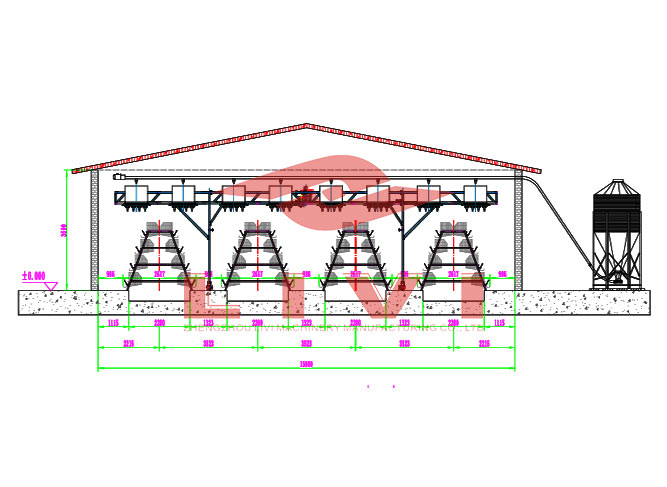

The poultry house was constructed using a 4-row × 4-tier layout, each row holding 7,500 birds, totaling 30,000 hens. The house was designed for optimal ventilation, durability, and workflow efficiency.

Delivered Equipment:

- 188 sets of 4-Tier Layers Cages (hot-dip galvanized)

- 4 automatic feeding machine

- 4 manure removal machines with PVC belts and motors

- 4 egg collection lines with lifting conveyors and collection tables

- Water supply system with filter tanks

- Spare parts, installation guides, and video support

Installation and Support

Due to the scale of the project, Livi Machinery dispatched professional engineers to the site in Rwanda. With the help of local construction workers, the system was fully installed within five weeks. After installation, our team provided comprehensive training on:

- Equipment operation and maintenance

- Daily bird management in cage systems

- Automated egg and manure handling procedures

This helped the farm team quickly adapt to the new system and begin production smoothly.

Client Feedback

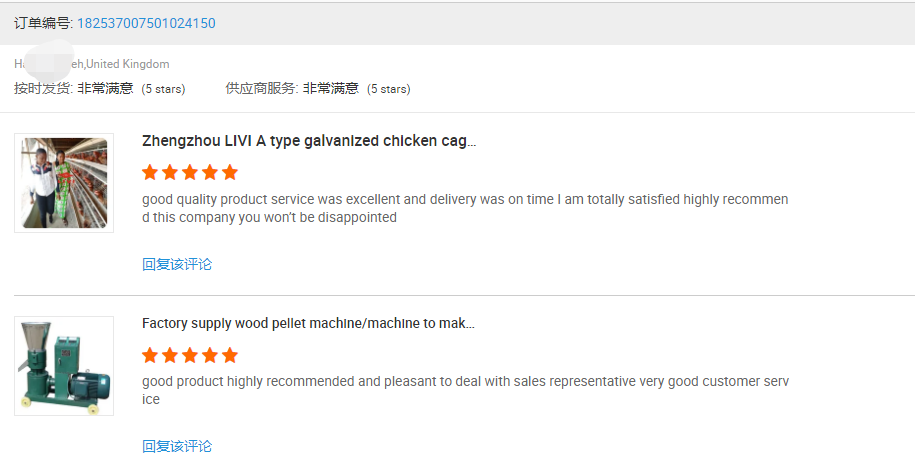

The client was highly satisfied with the cage quality, equipment efficiency, and overall layout design. The 4-Tier Layers Cages demonstrated excellent durability, even egg distribution, and minimal feed wastage. Automation significantly reduced labor intensity and improved hygiene conditions across the entire poultry house.

Thanks to the efficient operation of the system, the farm achieved an average daily output of 28,000–29,000 eggs, helping them meet commercial demand more reliably.

Why Choose Livi’s 4-Tier Layers Cages?

Livi Machinery provides professional poultry solutions tailored to each client’s needs. Our 4-Tier Layers Cages are ideal for medium to large-scale egg farms looking for:

- Maximum capacity in limited space

- Full automation to reduce labor and improve efficiency

- Durable, corrosion-resistant cage materials

- Professional layout planning and technical support

We have served over 70 countries with one-stop poultry farm solutions. Let Livi help you build a smarter poultry future.