Layer Cages for 90,000 Birds in Kenya: A Comprehensive Guide for Poultry Farmers and Investors

Understanding Layer Cages for Large Scale Poultry Operations

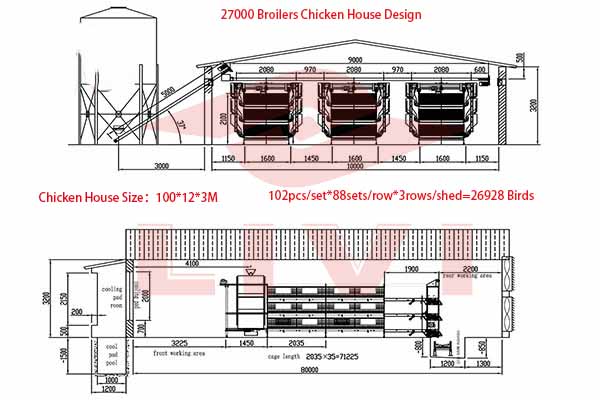

In the thriving poultry industry of Kenya, managing a large-scale operation, such as housing 90,000 birds, requires careful planning and efficient equipment. One of the most crucial components in this process is the layer cages. These cages are designed to maximize space usage, ensure bird welfare, and streamline the egg collection process. In this article, we will explore the best practices and considerations for layer cages in a 90,000-bird operation in Kenya.

According to recent statistics, Kenya’s poultry industry has seen a significant increase in the number of birds raised, with an estimated 3.6 million layers in production. This growth highlights the need for high-quality layer cages that can accommodate large flocks while maintaining optimal conditions.

Key Factors to Consider When Choosing Layer Cages

- Material and Construction: Opt for sturdy, durable materials that can withstand the weight of the birds and last for several years. Common materials include steel and plastic.

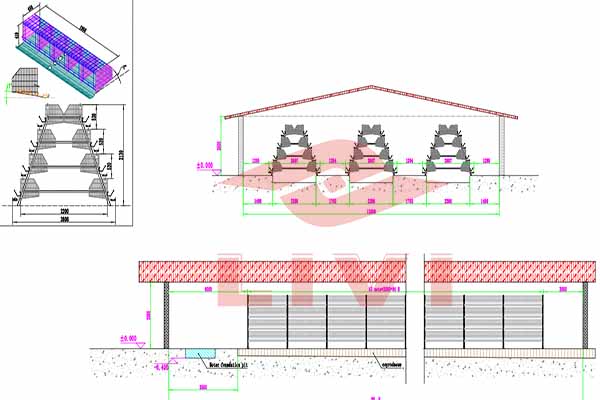

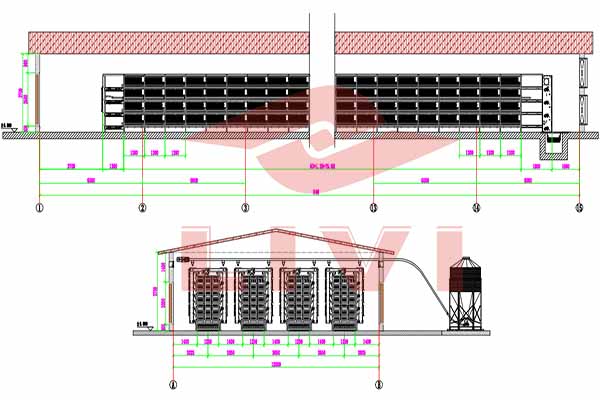

- Size and Layout: Ensure that the cages are appropriately sized for your birds and designed to provide enough space for movement and growth. Cages should be laid out in a way that minimizes stress and maximizes egg production.

- Airflow and Temperature Control: Good ventilation is essential for maintaining optimal temperature and humidity levels in the chicken house. Layer cages should allow for efficient airflow without causing drafts.

- Egg Collection System: A reliable and efficient egg collection system is crucial for a large-scale operation. Look for cages that are easy to clean and have a seamless egg collection process.

Layer Cages for 90,000 Birds in Kenya: Case Study

Let’s take a look at a case study of a successful layer cage operation in Kenya, which managed to house 90,000 birds efficiently:

| Parameter | Value |

|---|---|

| Total Birds | 90,000 |

| Layer Cages Used | 1,000 |

| Cage Material | Steel |

| Egg Collection System | Automatic |

| Average Egg Production per Day | 60,000 |

The success of this operation can be attributed to the use of high-quality layer cages that met all the necessary criteria mentioned earlier.

Why Choose LIVI Mechanical for Your Layer Cages

LIVI Mechanical offers a wide range of layer cages designed specifically for large-scale poultry operations like the one in Kenya. Here’s why you should choose us:

- Expertise: With years of experience in the poultry industry, our team understands the unique challenges faced by large-scale farmers.

- Customization: We offer customized layer cage solutions that cater to your specific needs, ensuring optimal performance and efficiency.

- Quality Assurance: Our products are made using high-quality materials and are designed to last for years.

- After-Sales Support: We provide comprehensive after-sales support to ensure that your layer cage operation runs smoothly.

For more information on our layer cages for 90,000 birds in Kenya, or to request a free design and equipment quote, please feel free to contact us. We are here to help you make the best decisions for your poultr<img src="http://www.livimachinery.com/wp-content/uploads/2025/05/how-much-does-it-cost- to-build-a-30000-broilers-poultry-farm-in-uganda-2.jpg” alt=”inserted image”>y operation.

to-build-a-30000-broilers-poultry-farm-in-uganda-2.jpg” alt=”inserted image”>y operation.

Don’t hesitate to reach out to us with any questions or concerns. Together, we can take your poultry farming business to new heights.

, , , ,