Optimizing Chicken Farm Cage Design in Tanzania: A Comprehensive Guide

As the demand for poultry products continues to rise in Tanzania, efficient and modern chicken farm cage design has become crucial for both productivity and animal welfare. This article explores the latest trends and considerations in chicken farm cage design, tailored specifically for the Tanzanian market.

Understanding the Tanzanian Chicken Farming Industry

The Tanzanian poultry industry has witnessed significant growth over the past decade. To keep up with this demand, it is essential to design chicken farms that are not only cost-effective but also conducive to the health and well-being of the birds.

- Market Size: Tanzania’s poultry industry is expected to grow at a CAGR of 4.2% from 2021 to 2026.

- Consumption: The per capita consumption of poultry meat is increasing, with a significant portion of the population preferring cage-reared chickens.

- Health and Welfare: The welfare of the chickens is a top priority, with regulations increasingly focusing on the design of chicken farm cages.

Key Aspects of Chicken Farm Cage Design in Tanzania

When designing chicken farm cages in Tanzania, several factors should be considered to ensure optimal performance and animal welfare.

Material Selection

High-quality steel is the preferred material for chicken farm cages due to its durability and resistance to corrosion. Galvanized steel, in particular, is ideal as it offers additional protection against rust and weathering.

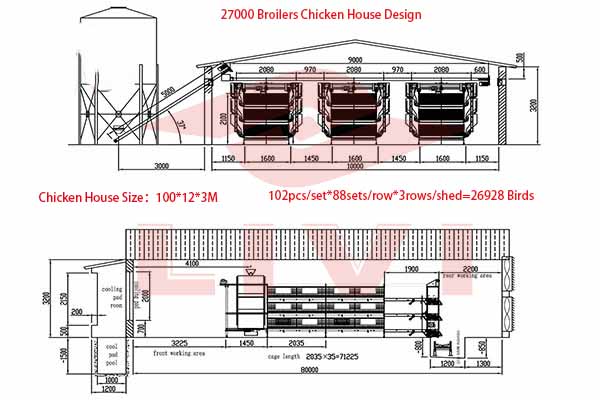

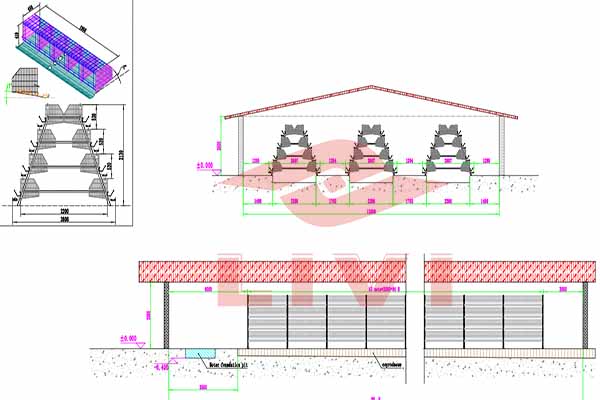

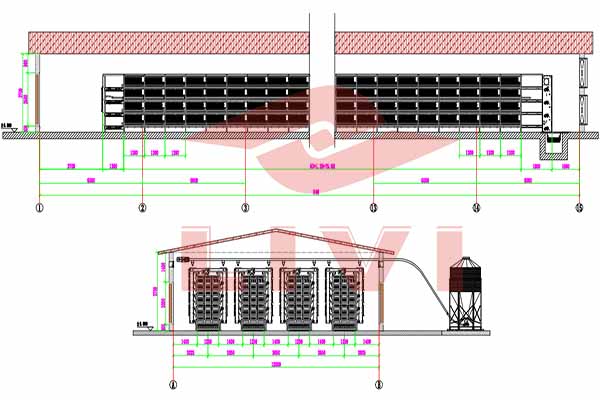

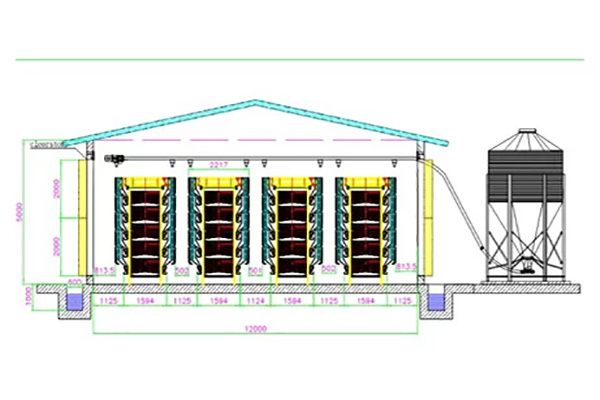

Cage Dimensions

The size of the chicken farm cages should be designed to accommodate the specific breed of chicken, ensuring ample space for movement and growth. A general guideline is to provide at least 0.4 square meters per bird.

Ventilation and Lighting

Proper ventilation and lighting are crucial for maintaining a healthy environment within the chicken farm. Natural lighting should be maximized, and mechanical ventilation systems should be installed to regulate temperature and humidity.

Manure Management

Efficient manure management is essential for maintaining hygiene and reducing the risk of disease. Slatted floors and automated manure removal systems are effective solutions for this purpose.

<img src="http: //www.livimachinery.com/wp-content/uploads/2025/05/project-of-30000-chickens-battery-cage-for-sale-in-south-africa-9.jpg” alt=”inserted image”>

//www.livimachinery.com/wp-content/uploads/2025/05/project-of-30000-chickens-battery-cage-for-sale-in-south-africa-9.jpg” alt=”inserted image”>

Case Study: Successful Chicken Farm in Tanzania

A successful chicken farm in Tanzania has implemented the following design elements:

- Galvanized Steel Cages: High-quality, durable cages with a lifespan of over 10 years.

- Optimal Cage Dimensions: 0.5 square meters per bird, providing ample space for growth and movement.

- Advanced Ventilation and Lighting: Natural lighting with automated mechanical ventilation systems.

- Automated Manure Removal: Slatted floors with an automated manure removal system.

As a result, this farm has experienced a 20% increase in productivity and a 15% reduction in disease incidence.

Contact Us for Free Chicken Farm Design and Equipment Quotation

Are you looking to optimize your chicken farm in Tanzania? Contact us today to get a free, customized chicken farm design and equipment quotation from LIVI Mechanical. Our team of experts will provide you with the best solutions to meet your specific needs.