Broiler Housing Equipment for 130,000 Birds in Tanzania: A Comprehensive Guide

As the poultry industry in Tanzania continues to grow, understanding the best practices for broiler housing is crucial for farm owners and investors alike. In this article, we delve into the equipment needed for a broiler housing system that can accommodate up to 130,000 birds, providing insights that can help optimize productivity and efficiency.

Overview of Broiler Housing Equipment

Broiler housing equipment is designed to create a controlled env ironment that supports the health, growth, and comfort of the birds. The following are some essential components for housing 130,000 birds in Tanzania:

ironment that supports the health, growth, and comfort of the birds. The following are some essential components for housing 130,000 birds in Tanzania:

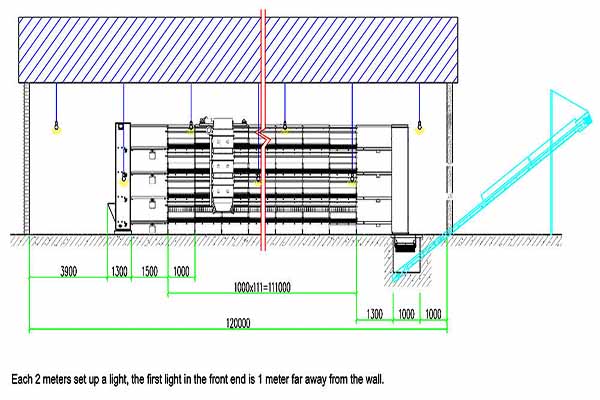

- Ventilation Systems: To ensure proper air circulation and temperature control, ventilation systems are essential. In a large-scale operation, this might include ceiling fans, exhaust fans, and air inlets.

- Feeding Systems: Automated feeding systems that provide consistent feed portions throughout the day can help maintain bird health and productivity. Consider the capacity and speed of the feeders for your specific flock size.

- Watering Systems: Access to clean, fresh water is vital for bird health. High-capacity watering systems that are reliable and easy to clean are a must.

- Environmental Control: Temperature, humidity, and ammonia levels must be carefully managed. Using sensors and automated control systems can help achieve this balance.

- Health Management: Equipment for monitoring and managing bird health, such as thermometers, scales, and disinfection systems, should be included.

Data shows that the optimal temperature for broiler chickens is around 18-24°C (64.4-75.2°F) during the firs t two weeks, after which it can gradually decrease to about 16-22°C (60.8-71.6°F) to maximize growth and efficiency.

t two weeks, after which it can gradually decrease to about 16-22°C (60.8-71.6°F) to maximize growth and efficiency.

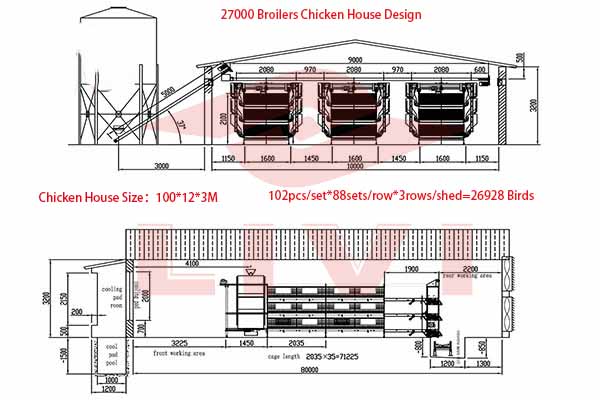

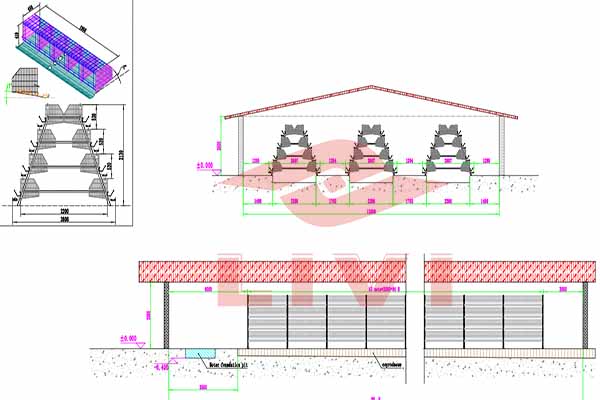

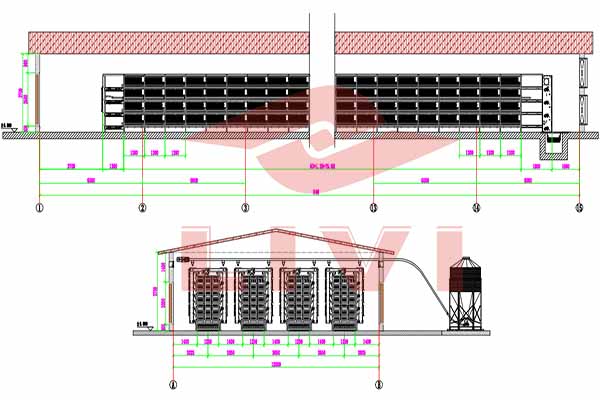

Design Considerations for 130,000 Birds

When designing a broiler housing facility for 130,000 birds, it is important to consider the following factors:

- Space Allocation: Adequate space per bird is crucial for the overall health and performance of the flock. Typically, 1.5 square meters per bird is recommended.

- Layout: A well-thought-out layout minimizes stress and maximizes the efficiency of the equipment.

- Biosecurity: Implementing biosecurity measures to prevent disease is critical in large-scale poultry operations.

- Renewable Energy: Using renewable energy sources, such as solar panels, can reduce operating costs and carbon footprint.

According to the Tanzania Poultry Board, the poultry industry in Tanzania is expected to grow by 6% annually. Therefore, investing in a well-designed broiler housing system can lead to significant financial gains.

Conclusion

Investing in the right broiler housing equipment for your 130,000-bird operation in Tanzania can significantly impact your farm’s success. By following best practices and utilizing the latest technologies, you can achieve high productivity and efficient management of your poultry flock.

For a detailed free design plan and equipment quote for your broiler housing needs, please feel free to leave a comment or contact us directly. Our team at Livi Machinery is committed to helping you build a sustainable and profitable poultry operation.