Battery Layer Cage Systems for 50,000 Chickens in Uganda: A Comprehensive Guide

Understanding the Need for Efficient Chicken Caging in Uganda

In the fast-growing poultry industry of Uganda, raising 50,000 chickens requires a robust and efficient caging system. Battery layer cages are a popular choice for commercial poultry farming due to their space-saving design and ease of management. This article delves into the essential aspects of implementing a battery layer cage system for 50,000 chickens in Uganda.

Key Features of a Battery Layer Cage System

– Space Optimization: Battery cages are designed to maximize space utilization, allowing you to house more chickens per square meter compared to traditional floor systems.

– Easy Management: The structured design of battery cages makes it easier to manage and monitor the health of your chickens.

– Health Benefits: Battery cages reduce the risk of disease transmission and allow for easier cleaning and disinfection.

– Automated Feeding and Watering Systems: Integrating automated systems can significantly improve efficiency and reduce labor costs.

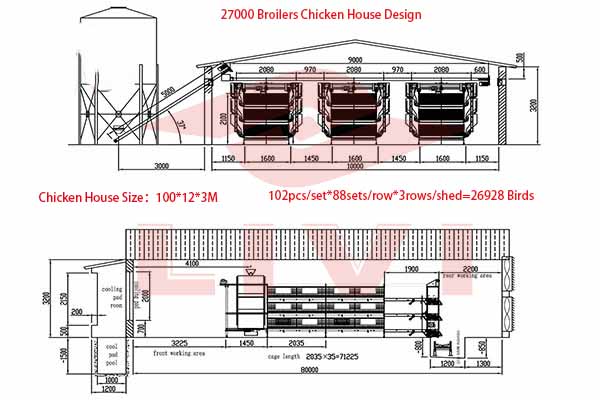

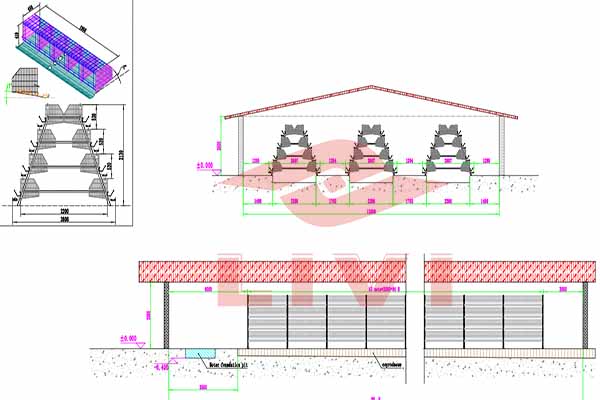

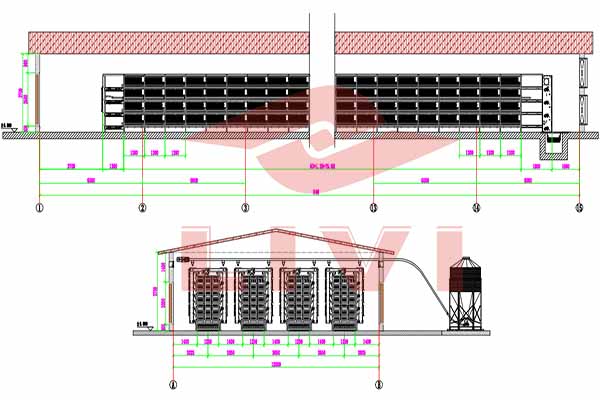

Designing a Battery Layer Cage System for 50,000 Chickens

To design an efficient battery layer cage system for 50,000 chickens, consider the following factors:

– Cage Size: Ensure each cage is large enough to accommodate the chickens comfortably. A typical cage size for laying hens is 2.5 square meters.

– Number of Cages: Divide the total number of chickens by the cage size to determine the number of cages required.

– Ventilation and Lighting: Proper ventilation and lighting are crucial for the health and productivity of your chickens. Ensure each cage has adequate ventilation and access to natural light.

– Flooring: Use a non-slip, easy-to-clean flooring material to maintain hygiene and prevent injury to the chickens.

Cost-Effectiveness and Return on Investment

The initial investment in a battery layer cage system can be substantial. However, the long-term benefits, such as increased productivity, reduced labor costs, and improved health of your chickens, can make it a worthwhile investment. According to a study by the International Poultry Council, a well-designed battery cage system can provide a return on investment of up to 20% within three years.

Conclusion

Implementing a battery layer cage system for 50,000 chickens in Uganda can significantly enhance your poultry farming operation. By considering the key features, designing an efficient system, and understanding the cost-effectiveness, you can make an informed decision for your business.

For more information and a free design consultation, please leave a comment below. Our team at LIVI Mechanical is here to help you with all your poultry farming needs.