Optimizing Chicken Battery Cages for 120,000 Chickens in Uganda: A Comprehensive Guide

Uganda’s poultry industry has been experiencing rapid growth, with a significant increase in the number of chickens being raised. One of the most critical components of large-scale chicken farming is the use of efficient and humane battery cages. In this article, we will discuss the design and implementation of battery cages for a 120,000-chicken operation in Uganda.

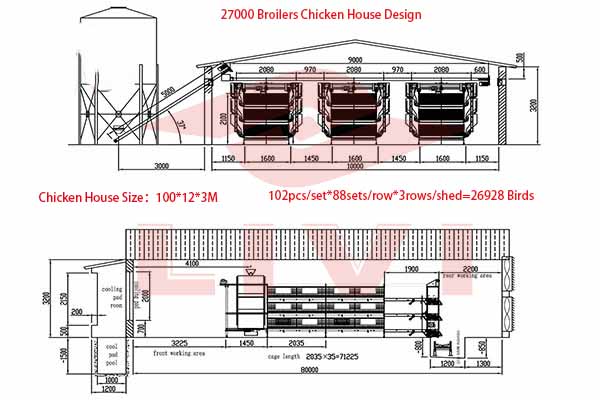

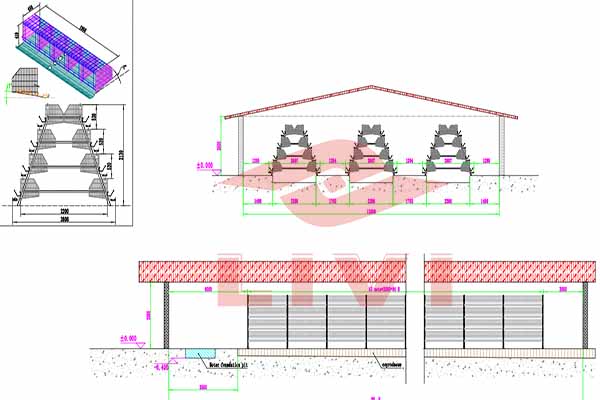

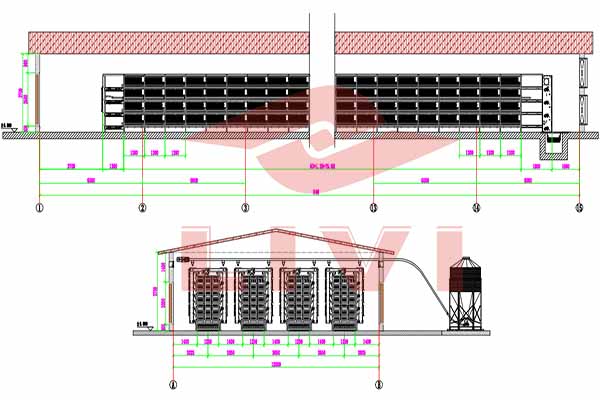

Designing Battery Cages for 120,000 Chickens

Properly designing battery cages for 120,000 chickens requires careful consideration of several factors:

- Space Allocation: Each chicken requires adequate space to move and spread its wings. A general guideline is to allocate approximately 0.2 square meters per bird.

- Airflow and Ventilation: Good airflow is essential for maintaining a healthy environment. Ensure that the cages are well-ventilated to prevent heat stress and the build-up of ammonia.

- Material Quality: Use durable materials that are resistant to corrosion and wear. Stainless steel or galvanized steel are ideal options.

- Ease of Cleaning: The design should allow for easy cleaning to prevent the spread of diseases.

For a 120 ,000-chicken operation, you can divide the birds into multiple batches of 20,000-30,000. This approach will make it easier to manage and maintain the chickens.

,000-chicken operation, you can divide the birds into multiple batches of 20,000-30,000. This approach will make it easier to manage and maintain the chickens.

Implementing Battery Cages in Uganda

Implementing battery cages in Uganda requires attention to several local factors:

- Compliance with Local Regulations: Make sure that your battery cage design complies with Ugandan animal welfare standards and environmental regulations.

- Local Supplier Availability: Identify local suppliers of materials and components to reduce shipping costs and lead times.

- Skilled Labor: Hire and train local labor to ensure that the installation and maintenance of the b

attery cages are carried out effectively.

attery cages are carried out effectively.

According to a study by the National Agricultural Research Organization (NARO), implementing battery cages can increase productivity by up to 20%. This means that a 120,000-chicken operation can produce an additional 24,000 birds per year, assuming optimal conditions.

Cost Analysis

The cost of installing battery cages for 120,000 chickens in Uganda can vary depending on the size and quality of the cages, as well as local labor and material costs. However, a general estimate is that it could cost around $150,000 – $200,000.

| Item | Cost Estimate (USD) |

|---|---|

| Material and Components | $75,000 – $100,000 |

| Installation | $30,000 – $40,000 |

| Labor and Training | $20,000 – $30,000 |

| Supervision and Management | $25,000 – $35,000 |

With the expected increase in productivity, the return on investment (ROI) can be realized within 2-3 years.

Conclusion

Designing and implementing battery cages for a 120,000-chicken operation in Uganda requires careful planning and consideration of various factors. By following the guidelines mentioned in this article, you can ensure that your operation is both efficient and humane.

For more information on our custom battery cage solutions and free design consultations, please feel free to leave a comment below or contact us directly.