Automatic Chicken Cage System for 30,000 Chickens in Uganda: A Comprehensive Guide

Introduction to the Automatic Chicken Cage System

The poultry industry in Uganda is experiencing significant growth, with an increasing demand for efficient and scalable solutions. For large-scale chicken farming operations, an automatic chicken cage system is a game-changer. This article explores the benefits and implementation of an automatic chicken cage system designed for a 30,000 chicken capacity.

Key Features of the Automatic Chicken Cage System

– Automated Feeding: With the capacity to feed up to 30,000 chickens, the system ensures a consistent and balanced diet, leading to healthier birds.

– Water Supply: Automated water supply ensures that chickens have access to clean water at all times.

– Climate Control: The system includes climate control mechanisms to maintain optimal temperatures for the chickens, reducing stress and improving growth rates.

– Health Monitoring: Integrated health monitoring systems track the well-being of the chickens, alerting farmers to potential issues early.

Benefits of Implementing an Automatic Chicken Cage System

– Increased Productivity: The system allows for a higher density of chickens per square meter, maximizing land use.

– Reduced Labor Costs: Automation reduces the need for manual labor, leading to cost savings.

– Improved Hygiene: Automated systems minimize the risk of disease transmission among chickens.

– Better Egg Quality: The controlled environment contributes to better egg quality and higher yields.

Case Study: Success Story in Uganda

In a recent implementation, a 30,000 chicken capacity automatic chicken cage system was installed in Uganda. The results were impressive:

– Increased Egg Production: The farm saw a 20% increase in egg production within the first year.

– Cost Savings: The farm achieved a 15% reduction in operational costs.

– Healthier Chickens: The chickens were healthier with a lower incidence of disease.

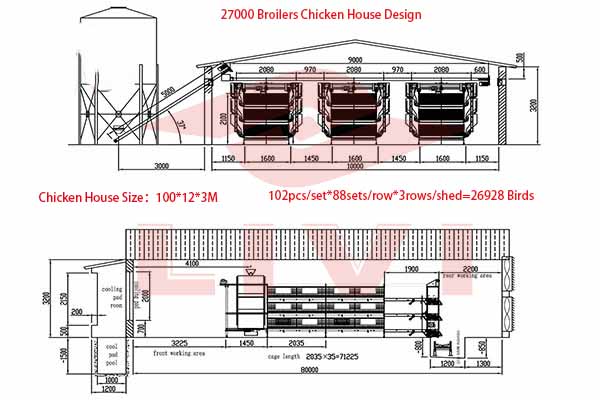

Technical Specifications

– Cage Capacity: 30,000 chickens

– Feeding System: Automated feeding with capacity for 100 kg/hour

– Water Supply: Automated water supply with a capacity of 10,000 liters/day

– Climate Control: Temperature and humidity control with a range of 18-25°C and 40-60% humidity

Implementation Process

1. Site Assessment: A thorough assessment of the farm’s layout and infrastructure is conducted.

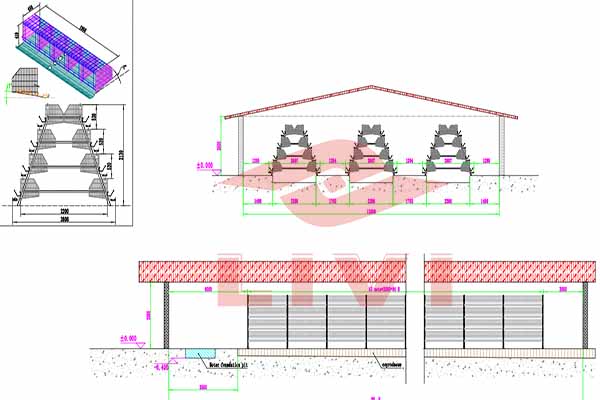

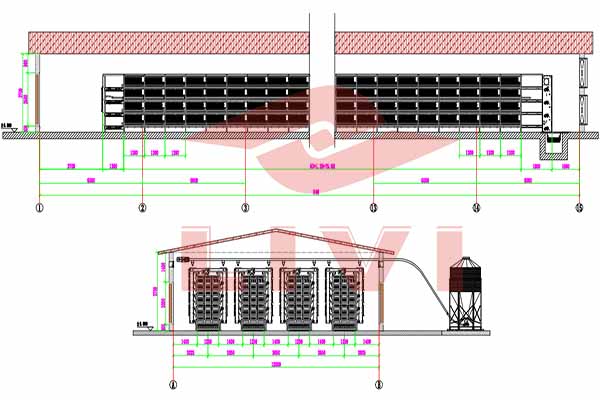

2. System Design: Customized design based on the farm’s specific needs.

3. Installation: Professional installation by trained technicians.

4. Training: Comprehensive training for farm staff on system operation and maintenance.

Conclusion

Investing in an automatic chicken cage system for a 30,000 chicken capacity in Uganda can revolutionize your poultry farming operation. With increased productivity, reduced labor costs, and improved health outcomes, it’s a smart choice for any poultry farmer or investor.

For more information or to discuss your specific needs, please leave a comment below. We offer free, customized chicken farming design plans and equipment quotes from LIVI Machinery. Contact us today to get started!