A-Type Layer Chicken Cages for 15,040 Birds Poultry Farm in Zambia

Project Overview

In May 2022, Livi Machinery successfully supplied and installed a set of A-Type Layer Chicken Cages for a layer poultry farm in Zambia. The farm was designed to house 15,040 laying hens, adopting a well-ventilated open-style poultry house and semi-automated equipment to achieve stable, efficient egg production while controlling overall investment costs.

Client Requirements and Our Solution

The Zambian client required:

- A reliable cage system for over 15,000 laying hens

- Strong, anti-corrosion cages suitable for the local climate

- Equipment compatible with open-house ventilation

- Partial automation to reduce labor but keep operational costs reasonable

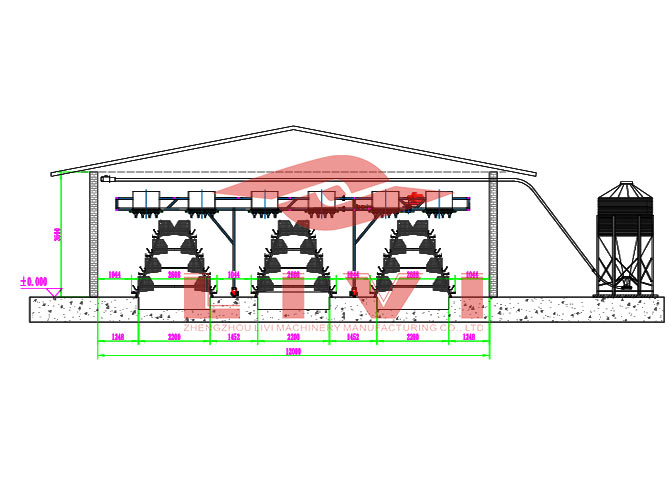

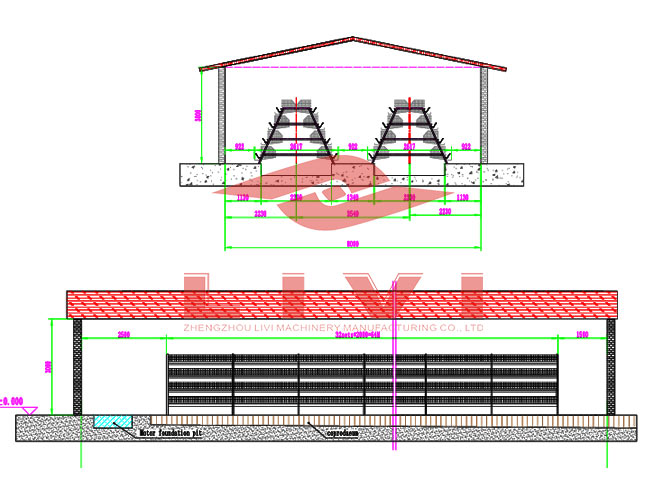

Livi Machinery designed a solution using 94 sets of A-Type Layer Chicken Cages, each with 4 tiers and 160-bird capacity. The cages were arranged in 2 rows, with 47 groups per row, housed inside a 98m × 10m open-sided poultry house. This setup was paired with gantry feeding and scraper-type manure cleaning systems.

Farm Layout and Equipment Supplied

- 94 sets of A-Type Layer Chicken Cages (4-tier, hot-dip galvanized)

- 1 gantry-type automatic feeding machine (serving both rows)

- 1 scraper-type manure cleaning machine (one-to-two system for 2 rows)

- Nipple drinking system with water pressure regulators

- Manual egg collection

The open-sided house design ensured natural ventilation, and the equipment configuration balanced productivity, labor reduction, and cost-efficiency.

Installation and Support

Livi Machinery provided:

- Detailed house layout and cage placement plans

- Remote installation guidance and video support

- Online training for local staff on operating gantry feeder and scraper system

- Ongoing after-sales service and spare parts support

The installation was completed in less than 4 weeks, with the farm quickly entering full production.

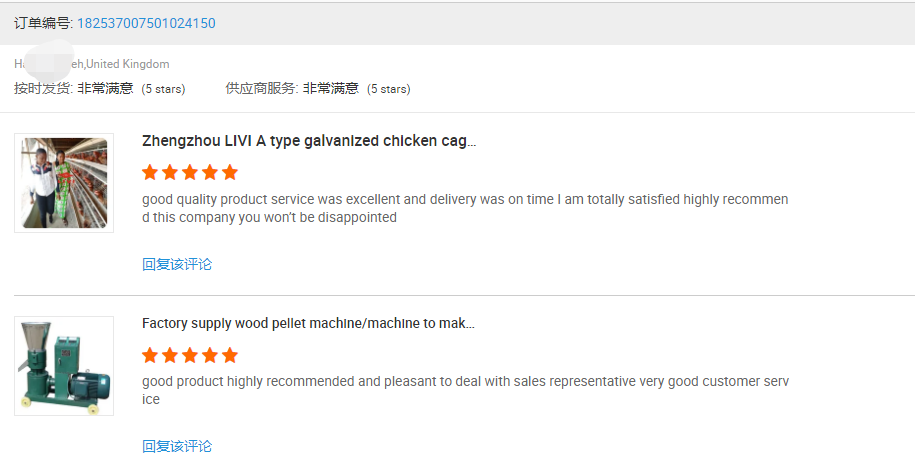

Customer Feedback

The client expressed high satisfaction with:

- The structural strength and rust resistance of the cages

- Efficient daily feeding using the gantry system

- Smooth and sanitary manure removal via scraper cleaner

- Responsive communication and technical support from Livi’s team

Why Partner with Livi Machinery?

As a leading supplier of poultry farming equipment, Livi Machinery has been dedicated to providing global poultry farmers with reliable, efficient, and customized layer cage systems since 2012. Our core advantages include:

- ✅ Rich Industry Experience

With over 12 years of experience and 1,000+ projects delivered in more than 70 countries, we understand the real needs of farmers and offer solutions that work. - ✅ High-Quality Manufacturing

All cages are made from hot-dip galvanized steel, ensuring long service life, excellent corrosion resistance, and safety for birds even in tropical or coastal environments. - ✅ One-Stop Farm Solutions

From farm design and layout to equipment production, shipping, installation guidance, and after-sales service—Livi offers one-stop poultry farm support. - ✅ Customization for Local Conditions

Whether you are building an open-sided house in Africa or a closed shed in the Middle East, we tailor equipment configuration to fit your climate, budget, and scale. - ✅ Professional Service Team

Our team of over 70 professionals provides technical consultation, CAD farm planning, multilingual support, and remote/on-site installation assistance. - ✅ Global Installation Network

We provide local installation teams or on-site supervisors in over 30 countries, helping customers start production faster and with peace of mind.