H Type Battery Chicken Cage System for 50,000 Layers in Kenya

Project Overview

In 2023, a large-scale egg farm in Kenya cooperated with LIVI Machinery to set up a commercial layer house for 50,000 chickens using the H Type Battery Chicken Cage System. This system was selected for its high space efficiency, automated operation, and suitability for closed poultry houses in hot climates.

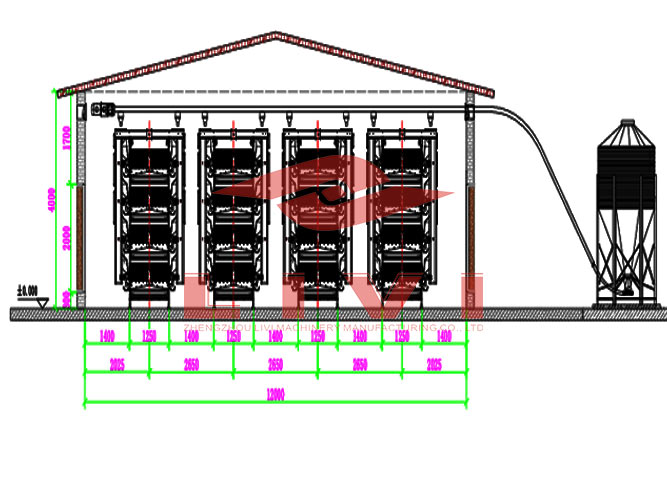

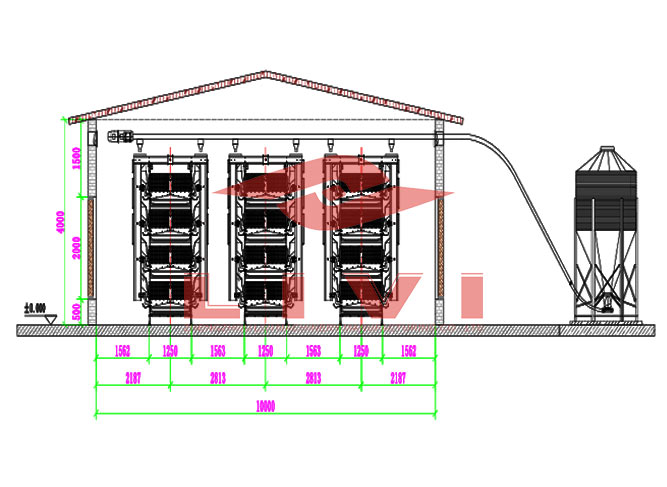

To meet the customer’s large-capacity requirement within a single chicken house, LIVI designed a customized 5-row layout using 4-tier H type cages, fully equipped with automatic systems for feeding, egg collection, manure removal, and environmental control. The project helped the client achieve high-density farming with stable performance and reduced labor costs.

Project Details

Location: Kenya

Farming Scale: 50,000 laying hens

Cage Model: H Type Battery Chicken Cage System – 4 Tiers

Chicken House Layout: Single house, 5 rows

Total Cage Sets: 350 sets (70 sets per row × 5 rows)

Birds per Cage Set: 144 birds

Total Capacity: 50,400 birds

Chicken House Size: Approx. 93 meters long × 12 meters wide

Client Requirements and LIVI’s Solution

Client Requirements:

- Housing system for 50,000 layers within a single modern poultry house

- Full automation to support intensive production with minimal labor

- Effective temperature and ventilation control for a closed house

- Durable equipment with long service life

LIVI’s Solution with H Type Battery Chicken Cage System:

- Designed a closed poultry house with 5 rows of H type battery cages, 4 tiers per set

- Provided 350 sets of cages, each capable of housing 144 birds

- Integrated automatic systems for feeding, manure removal, egg collection, and drinking

- Configured climate control with cooling pads, fans, side inlets, and ventilation tunnels

- Supported the client with design drawings, equipment layout, and remote technical guidance

Configuration of Automation and Climate Control System

| Automatic System | Configuration |

| Automatic Feeding System | 5 sets of feeding machines (1 per row) |

| Automatic Drinking System | Nipple drinking system with pressure regulators |

| Automatic Egg Collection System | 5 sets of automatic egg collection machines |

| Automatic Manure Cleaning | 5 sets of belt-type manure removal machines |

| Automatic Climate Control System | Cooling pads, exhaust fans, side windows, ventilation inlets |

The H Type Battery Chicken Cage System was installed inside a fully enclosed chicken house, designed to support year-round egg production and better control of environmental factors such as humidity, temperature, and airflow.

Client Feedback

The client in Kenya expressed great satisfaction with the performance of the H Type Battery Chicken Cage System. With 50,000 hens managed in one house, the system delivered consistent production and required minimal daily labor. The fully automated setup and enclosed structure improved biosecurity and management efficiency.

Why Choose LIVI H Type Battery Chicken Cage System

- Ideal for large-scale commercial layer farms

- Modular design fits various house layouts (2 to 5 rows)

- High space utilization and bird density

- Full automation reduces labor and increases efficiency

- Climate control integration supports closed house operations

- Durable and corrosion-resistant steel structure

- More than 1,000 successful cases worldwide

Contact LIVI today to start building your professional poultry farm with the H Type Battery Chicken Cage System.