H Type Battery Chicken Layer Cage System for 30,000-Bird Poultry Farm in South Africa

Project Overview

In 2025, a commercial poultry enterprise based in South Africa sought to expand its layer production to meet growing market demand for fresh eggs. The farm selected the H Type Battery Chicken Layer Cage System supplied by LIVI Machinery as the core equipment for its 30,000-bird automated layer house.

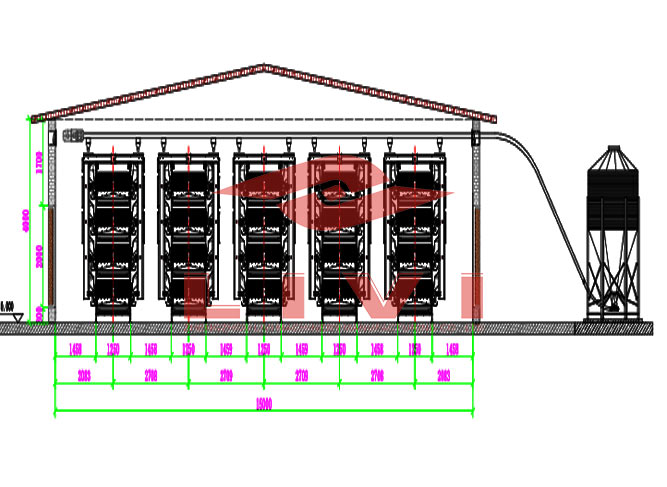

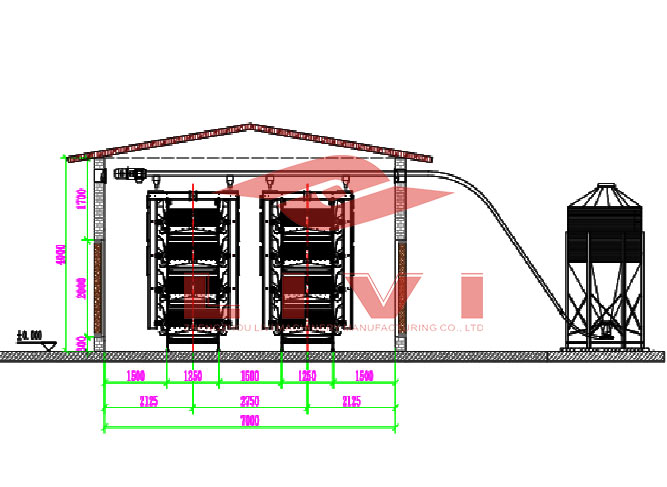

To ensure efficiency and stability, the client required a modernized housing solution with a high level of automation. LIVI’s team responded with a fully integrated 3-row cage system layout using 4-tier H-type cages, customized for a closed house environment. The project focused on reducing labor, improving egg yield, and ensuring a hygienic, controlled environment.

Project Details

Location: South Africa

Farming Scale: 30,000 laying hens

Cage Model: Battery Chicken Layer Cage System –H Type, 4 Tiers

Chicken House Layout: Single house, 3 rows

Total Cage Sets: 210 sets (70 per row)

Birds per Cage Set: 144 birds

Total Capacity: 30,240 birds

House Size: Approx. 93 meters long × 10 meters wide

Client Requirements and LIVI’s Solution

Client Requirements:

- Efficient and compact cage layout for 30,000 layers

- Full automation for key poultry house operations

- Strong, corrosion-resistant cages with long lifespan

- Stable climate control for egg production in varying weather

LIVI’s Solution with H Type Battery Chicken Layer Cage System:

- Designed a 3-row layout with 210 sets of 4-tier H-type cages

- Integrated all systems for feeding, egg collection, manure removal, and water supply

- Applied a closed house structure with environmental control for temperature and ventilation

- Delivered design drawings, installation guidance, and after-sales support

- Helped the client manage the entire flock with minimal labor and high efficiency

Configuration of Automation and Climate Control System

| Automatic System | Configuration |

| Automatic Feeding System | 3 sets of feeding machines (1 per row) |

| Automatic Drinking System | Nipple drinking system with pressure regulators |

| Automatic Egg Collection System | 3 sets of automatic egg collection machines |

| Automatic Manure Cleaning | 3 sets of belt-type manure removal machines |

| Automatic Climate Control System | Cooling pads, exhaust fans, side windows, ventilation inlets |

Client Feedback

The client reported that the Automated Chicken Layer Cage System significantly improved management efficiency. With fewer staff required for daily tasks, the automated systems ensured a constant and stable production flow. The cage structure proved to be durable and easy to maintain, and the enclosed house environment reduced mortality and disease risks.

Why Choose LIVI Automatic H Type Chicken Layer Cage System?

- Tailored for intensive commercial egg production

- Excellent ventilation and manure handling in closed houses

- Durable hot-dip galvanized structure resistant to rust and corrosion

- Compatible with full automation for large-scale farms

- Proven cage performance across Southern African climates

- Over 1,000 global poultry farm projects with professional support

Contact Us

ZHENGZHOU LIVI MACHINERY MANUFACTURING CO., LTD

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com

Start your successful poultry business with LIVI’s Automatic H Type Chicken Layer Cage System for maximum efficiency and production.