Automatic H Type Layer Cages for 35,000-Chicken Poultry Project in Argentina

Project Overview

In 2021, a large-scale poultry farm in Argentina chose to modernize its egg production by installing Automatic H Type Layer Cages supplied by LIVI Machinery. The client aimed to house 35,000 layers in a single closed chicken house with reliable automation, optimized space use, and high productivity under Argentina’s variable climate.

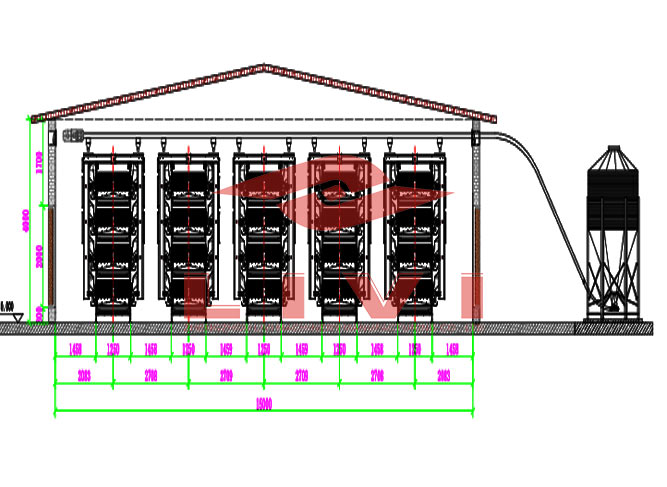

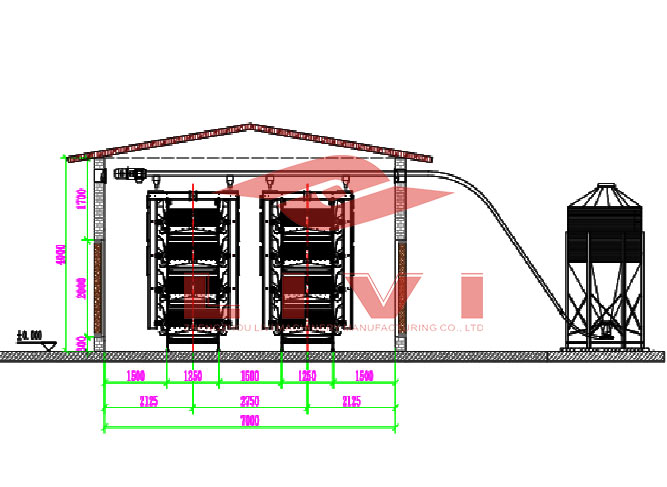

LIVI designed a 3-row layout using 5-tier H-type cages, along with a complete set of automated systems. From feeding and egg collection to manure removal and climate control, the entire setup was engineered for long-term performance, minimal labor, and consistent output.

Project Details

Location: Argentina

Farming Scale: 35,000 laying hens

Cage Model: Automatic H Type Layer Cages – 5 Tiers

Chicken House Layout: Single house, 3 rows

Total Cage Sets: 243 sets (81 per row)

Birds per Cage Set: 144 birds

Total Capacity: 34,992 birds

House Size: Approx. 108 meters long × 10 meters wide

Client Requirements and LIVI’s Solution

Client Requirements:

- Accommodate 35,000 layers in a single poultry house

- Automate all major operations to reduce manual labor

- Ensure stable production across seasonal changes

- Use durable cage equipment with long-term value

LIVI’s Solution with Automatic H Type Layer Cages:

- Customized a 3-row layout with 5-tier cages to meet capacity needs

- Provided 243 sets of Automatic H Type Layer Cages

- Configured complete automation for feeding, egg collecting, manure cleaning, and drinking

- Designed the house as a fully enclosed system with advanced ventilation and cooling

- Offered full planning support with layout drawings and technical guidance

Configuration of Automation and Climate Control System

| Automation System | Configuration |

| Automatic Feeding System | 3 sets of feeding machines (1 per row) |

| Automatic Drinking System | Nipple drinking system with pressure regulators |

| Automatic Egg Collection System | 3 sets of automatic egg collection machines |

| Automatic Manure Cleaning | 3 sets of belt-type manure removal machines |

| Automatic Climate Control System | Cooling pads, exhaust fans, side windows, ventilation inlets |

The Automatic H Type Layer Cages were housed in a well-ventilated closed poultry house, allowing for efficient temperature control and year-round egg production. The five-tier configuration allowed higher stocking density without compromising bird welfare or operational convenience.

Client Feedback

The Argentinian client highlighted the project’s smooth implementation and impressive output. Despite a high number of birds, daily operations were managed by only a few workers, thanks to the automation system. The 5-tier cage design also helped reduce the overall building footprint while meeting production goals efficiently.

Why Choose LIVI Automated H Type Layer Cages

- Space-saving multi-tier cage design ideal for large-scale projects

- Automated feeding, cleaning, and egg collection reduce labor

- High bird density in limited house width with 5-tier system

- Closed-house environmental control ensures year-round performance

- Proven durability and corrosion resistance with hot-dip galvanized cages

- One-stop service from planning to post-sale support

Contact Us

ZHENGZHOU LIVI MACHINERY MANUFACTURING CO., LTD

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com

LIVI helps commercial poultry farms scale efficiently with Automatic H Type Layer Cages tailored to your capacity, environment, and management goals.