H-Type Battery Cage System for 20,000 Layers Farm in Tanzania

Project Overview

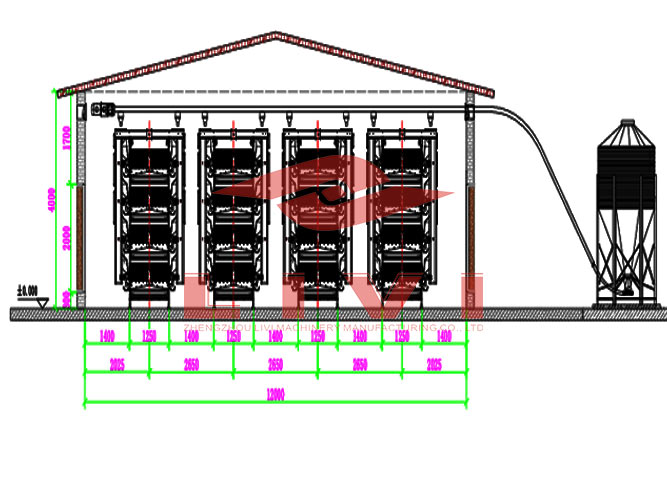

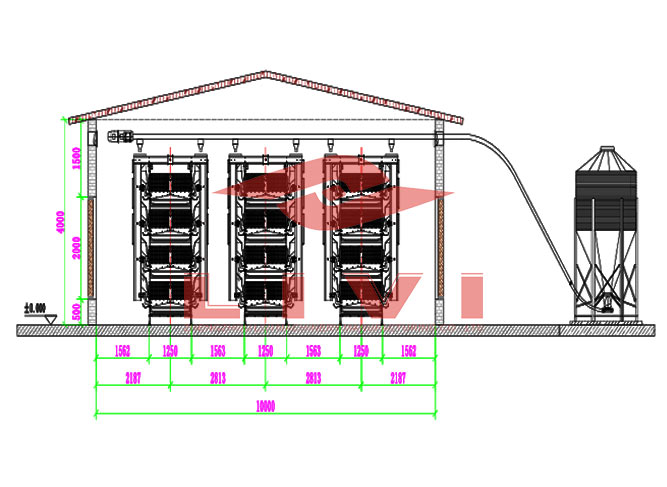

To meet the growing demand for high-efficiency egg production, a poultry farmer in Tanzania invested in a modern H-Type Battery Cage System designed to raise 20,000 laying hens. The farm features a single chicken house, equipped with H-type 4-tier chicken cages for layers, arranged in 2 rows. This compact yet efficient layout enables maximum space utilization, high-density rearing, and smooth daily management.

Client Requirements and Tailored Solution

The client aimed to set up a fully automated, easy-to-manage poultry house with stable egg production and reduced labor costs. Key concerns included durability, cleanliness, and automation.

Based on the farm size and operational goals, LIVI provided a complete H-type layer cage system solution. Our design team delivered a layout using 140 sets of 4-tier H-type chicken cages, each set capable of housing 144 birds. The project was supported with professional guidance, from layout design to equipment installation.

Equipment Supplied

- 140 sets of H-Type 4-tier battery cages (144 birds per set, hot-dip galvanized)

- Nipple drinking system with water tanks

- 2 set of automatic feeding machine (per house)

- 2 sets of belt manure removal system (one per row)

- 2 sets of automatic egg collection machine (one per row)

All systems were integrated for seamless automation, ensuring daily operations such as feeding, watering, waste removal, and egg collection are efficient and hygienic.

Key Features of the H-Type Battery Cage System

- Durability: Hot-dip galvanized cages ensure corrosion resistance and a service life of over 15 years

- Compact design: The 4-tier, 2-row layout maximizes bird capacity within limited floor space

- Full automation: Reduces manual labor and improves farm hygiene and egg quality

- Easy management: Centralized control of feeding and manure cleaning systems saves time and effort

Feedback from the Farm

The Tanzanian client expressed strong satisfaction with the performance of the H-type battery cage system. They highlighted the system’s efficiency in daily operations, cleaner environment, and noticeable improvement in egg production compared to previous methods. The automation significantly lowered labor costs while increasing productivity.

Why Choose LIVI’s H-Type Layer Cage System?

LIVI specializes in supplying professional poultry farming solutions to clients in Africa, Asia, and Latin America. Our H-Type Battery Cage Systems are widely used in modern poultry farms for their structural strength, high-density rearing capability, and excellent automation features.

With over a decade of experience and service in more than 70 countries, LIVI offers not just equipment, but full technical support—from layout planning to on-site or remote installation.

Contact Us for Your Poultry Project

Looking to build or upgrade your poultry farm in Tanzania or East Africa?

LIVI is ready to support your success.

📧 Email: [email protected]

📞 WhatsApp/WeChat: +86 155 3717 9350

🌐 Website: www.livimachinery.com