H-type Battery Cage System for 20,000 Layers Poultry Farm in Burkina Faso

Project Overview

In 2025, a poultry farm in Burkina Faso collaborated with LIVI Machinery to establish a modern layer breeding facility designed for 20,000 laying hens. The customer opted for the H-type Battery Cage System, a reliable and automated solution suitable for high-efficiency egg production under West African climate conditions.

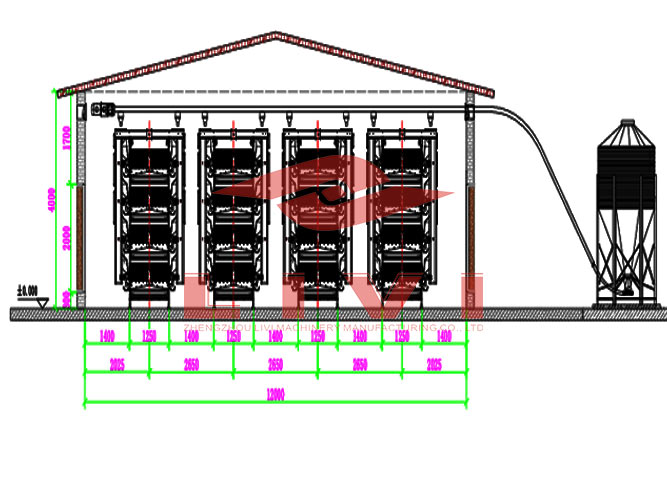

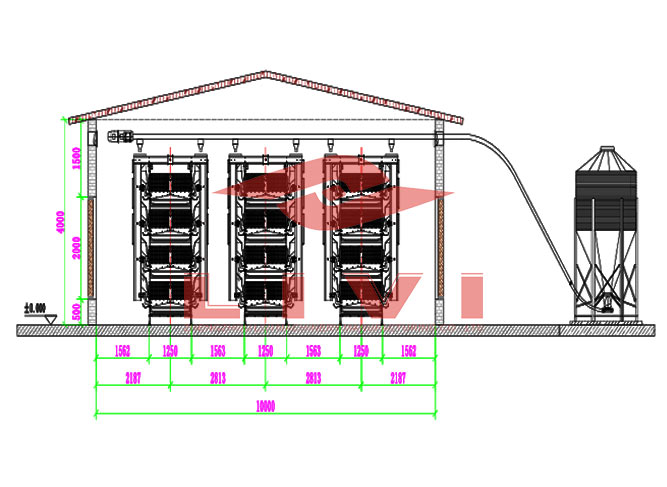

To meet the capacity and space limitations, LIVI designed a compact 2-row layout using 4-tier H-type cages, equipped with full automation for feeding, egg collection, manure removal, and environmental control. The system not only maximized house utilization but also minimized labor costs and disease risks through closed-house design.

Project Details

Location: Burkina Faso

Farming Scale: 20,000 laying hens

Cage Model: H-type Layer Battery Cage System – 4 Tiers

Chicken House Layout: Single house, 2 rows

Total Cage Sets: 140 sets (70 per row)

Birds per Cage Set: 144 birds

Total Capacity: 20,160 birds

House Size: Approx. 93 meters long × 7 meters wide

Client Requirements and LIVI’s Solution

Client Requirements:

- Efficient layout to house 20,000 layers in a compact building

- Automated systems to reduce labor and improve productivity

- Equipment durable enough for use in hot and dusty climates

- Closed house structure to reduce heat stress and improve egg output

LIVI’s Solution with H-type Battery Cage System:

- Supplied 140 sets of 4-tier H-type cages in a 2-row configuration

- Designed a 93m x 7m closed poultry house with optimized ventilation

- Installed automated systems for feeding, egg collection, manure cleaning, and drinking

- Integrated climate control with cooling pads, exhaust fans, and fresh air inlets

- Provided full project support including technical layout and installation guidance

Configuration of Automation and Climate Control System

| Automation System | Configuration |

| Automatic Feeding System | 2 sets of feeding machines (1 per row) |

| Automatic Manure Cleaning System | 2 sets of belt-type manure removal machines |

| Automatic Egg Collection System | 2 sets of automatic egg collection machines |

| Automatic Drinking System | Nipple drinking system with pressure regulators |

| Automatic Climate Control System | Cooling pads, exhaust fans, side windows, ventilation inlets |

The H-type Battery Cages Poultry Farming System was built to withstand the local environment while ensuring high levels of hygiene, efficiency, and egg production. The compact 2-row design allowed for easier house management and effective ventilation.

Client Feedback

The customer in Burkina Faso expressed satisfaction with the equipment performance and after-sales service. The automated design greatly reduced the need for manual labor, and the chickens adapted well to the indoor environment. The cage system has maintained stable production since operation began.

Why Choose LIVI H-type Layer Battery Cage System

- Space-saving cage layout for small and medium farms

- Full automation improves efficiency and reduces labor costs

- Strong structural durability for hot and dusty conditions

- Proven performance in closed-house egg farming systems

- Custom layout design, technical drawings, and on-site support available

- Delivered to over 70 countries with reliable customer satisfaction

Contact Us

ZHENGZHOU LIVI MACHINERY MANUFACTURING CO., LTD

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com

Partner with LIVI to upgrade your layer farm using the H-type Battery Cage System for reliable and cost-effective egg production.