H Type Layer Cage System for 60,000-Chicken Battery Cage Poultry Farming in Uzbekistan

Project Overview

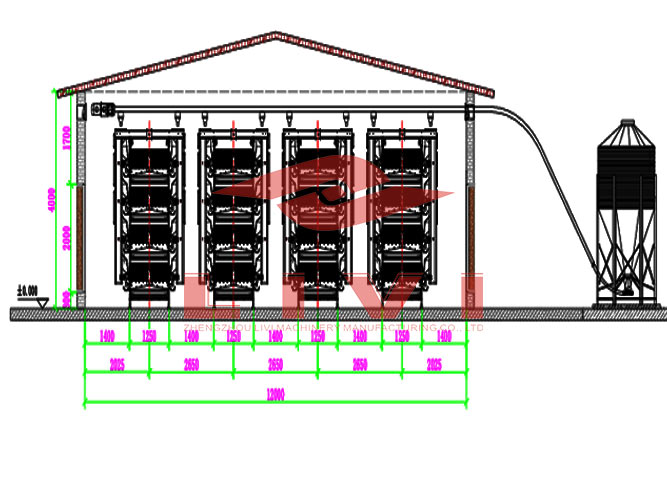

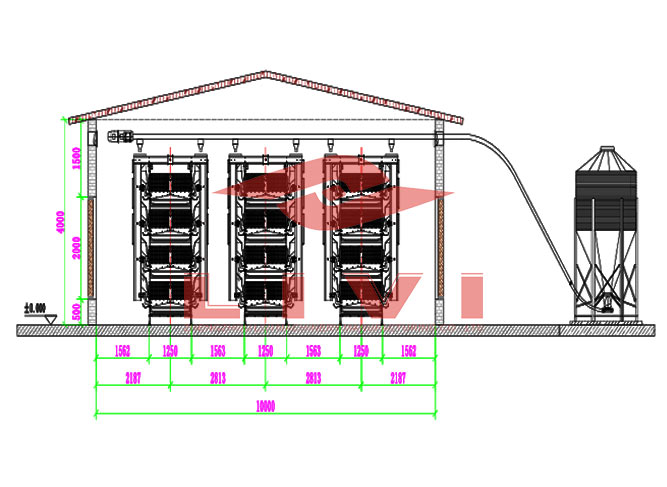

In 2025, a commercial poultry farm in Uzbekistan selected LIVI Machinery to provide a high-efficiency housing solution for 60,000 laying hens. To support this large-scale battery cage farming operation, the client adopted the H Type Layer Cage System featuring 5 tiers and a 4-row layout within a single closed house.

The project was designed to meet the client’s goals of maximizing space usage, reducing labor, and maintaining consistent egg production under Uzbekistan’s extreme seasonal climate conditions. With LIVI’s fully automated system integration and technical support, the poultry farm was able to achieve efficient operation from day one.

Project Details

Location: Uzbekistan

Farming Scale: 60,000 laying hens

Cage Model: Automatic Layer Cage System –H Type, 5 Tiers

Chicken House Layout: Single house, 4 rows

Total Cage Sets: 420 sets (105 sets per row × 4 rows)

Birds per Cage Set: 144 birds

Total Capacity: 60,480 birds

House Size: Approx. 117 meters long × 11 meters wide

Client Requirements and LIVI’s Solution

Client Requirements:

- Raise over 60,000 laying hens in a single poultry house

- Automate all key operations: feeding, manure removal, egg collection, and drinking

- Ensure equipment stability under Uzbekistan’s hot summers and cold winters

- Reduce manual workload and improve egg collection efficiency

LIVI’s Solution with H Type Layer Cage System:

- Configured 420 sets of 5-tier H Type Layer Cages in a 4-row layout

- Designed a 117-meter-long closed house to support full automation

- Installed complete systems for automatic feeding, egg collection, manure removal, and water supply

- Integrated ventilation and cooling components to ensure optimal airflow and temperature control year-round

- Provided installation layout, engineering support, and remote guidance

Configuration of Automation and Climate Control System

| System | Configuration |

|---|---|

| Automatic Feeding System | 4 sets of feeding machines (1 per row) |

| Automatic Manure Cleaning | 4 sets of belt-type manure removal machines |

| Automatic Egg Collection System | 4 sets of automatic egg collection machines |

| Automatic Drinking System | Nipple drinking system with pressure regulators |

| Automatic Climate Control System | Cooling pads, exhaust fans, side windows, ventilation inlets |

The H Type Layer Chicken Cage System was installed in a fully enclosed poultry house, allowing for effective disease prevention, consistent egg production, and efficient waste management in high-density conditions.

Client Feedback

The Uzbekistan client reported that the entire cage system and automation setup performed beyond expectations. Despite managing over 60,000 birds in one house, the operation remained organized and labor-efficient. The five-tier cage design helped save space while ensuring bird comfort and production stability.

Why Choose LIVI H Type Layer Cage System

- Five-tier configuration supports ultra-high-density farming

- Suitable for large-scale single-house projects with up to 60,000 birds

- Seamless integration with automatic feeding, cleaning, and egg collection systems

- Built for year-round operation under harsh climate conditions

- Made with hot-dip galvanized steel for durability and rust resistance

- Supported by technical drawings, layout design, and installation guidance

Contact Us

ZHENGZHOU LIVI MACHINERY MANUFACTURING CO., LTD

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com

Build your high-capacity poultry project with confidence using LIVI’s H Type Chicken Layer Cage System for large-scale egg production.