Automated H-Type Layer Chicken Cages for 30,000-Chicken Farm in Uganda

Objective Performance Data: Why H Type 4-Tier Layer Cage System Works for Medium-Scale Egg Farms

Ugandan poultry farmers expanding to 30,000 layers often ask:

- How can I efficiently manage 30,000 chickens with limited land and labor?

- Which cage system is durable in humid tropical climates?

- Is full automation realistic for a mid-size egg farm?

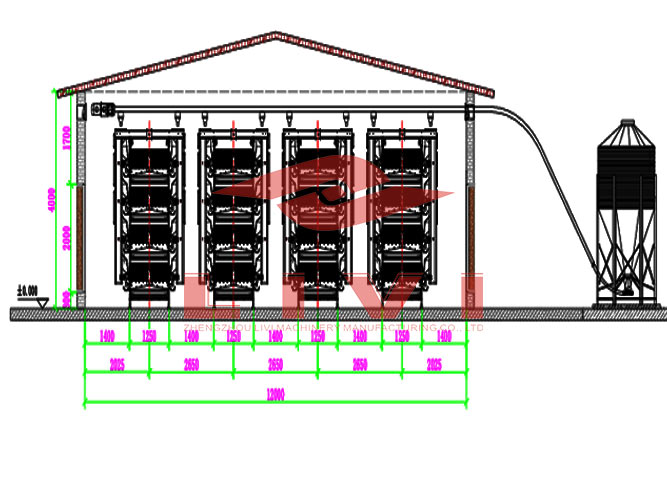

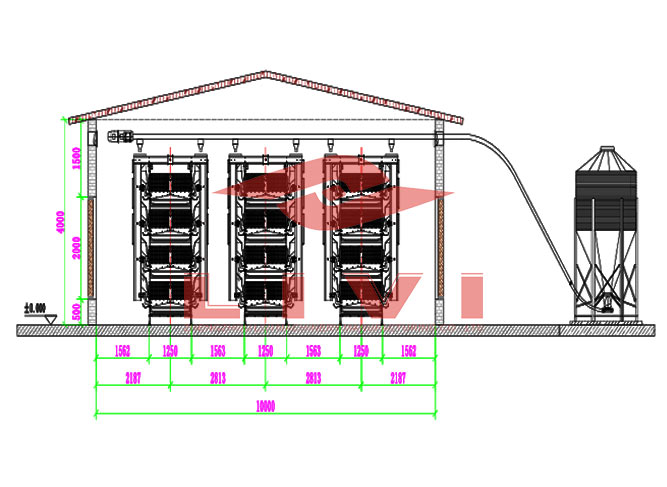

This project answers those questions. In 2025, a Ugandan poultry farm selected the Automated H Type 4-Tier Layer Cage System from LIVI Machinery, installing it in a single, fully enclosed chicken house with a 3-row cage layout. The system achieved excellent bird density, smooth automation, and long-term equipment reliability — all tailored to the local conditions.

Project Summary

- Location: Uganda

- Total Layer Capacity: 30,000 birds

- Cage System: H Type 4-Tier Layer Chicken Cages

- Cage Layout: 3 rows inside one chicken house

- Number of Cage Sets Installed: 210 sets

- Birds per Set: 144 birds

- Total Birds in Operation: 30,240 birds

- Automation Level: Fully automatic feeding, manure removal, egg collection

With 210 cage sets of the H Type 4-Tier model, the farm now manages over 30,000 layers within a single house, benefiting from reduced labor demands and improved hygiene.

Why the H Type Layer Chicken Cages Are a Smart Fit for Ugandan Poultry Farms

High Bird Capacity with Efficient Land Use

Using H-Type Battery Cages for Layers, the farm achieves high density without overcrowding. The 4-tier structure maximizes vertical space, enabling 30,240 birds to be housed in one building without sacrificing ventilation or accessibility.

Built to Last in Humid, Tropical Climates

Uganda’s warm and humid conditions can shorten equipment life. LIVI’s cages are made of hot-dip galvanized steel, resistant to corrosion and designed for a service life of 15–20 years even in tropical environments.

Full Automation Solves Labor Constraints

Rural Ugandan farms often operate with limited manpower. This system is designed for efficient daily operation with minimal staff and includes:

- 3 automatic feeding machine

- 3 belt-type manure cleaning systems (one per row)

- 3 automatic egg collection machines (one per row)

- Nipple drinking system with water tanks

These systems ensure consistent feed, egg collection, and waste disposal, reducing manual workload and boosting daily efficiency.

Equipment Supplied

| Equipment | Quantity | Description |

|---|---|---|

| H Type 4-Tier Layer Cage Sets | 210 sets | 144 birds per set, 30,240 birds total |

| Automatic Gantry Feeding Machine | 3 sets | One per house for centralized feeding |

| Belt Manure Cleaning System | 3 sets | One for each cage row |

| Egg Collection Machine | 3 sets | One per row, integrated collection system |

| Nipple Drinking System | Full set | With water tanks for all cage rows |

| Climate Control System | Customized | Includes fans, air inlets, and curtains |

Customer Feedback

“We wanted a solution that could hold 30,000 birds in one house without hiring a huge team. With LIVI’s H Type Layer Chicken Cage System, everything is automated and the birds stay healthy and productive. The system is durable and very clean. We’re confident this setup will serve us for many years.”

— Farm Owner, Uganda

The client appreciated how automation simplified operations and how the cage structure supported excellent bird health and egg output — even under humid conditions.

What Makes H-Type Battery Cages for Layers Ideal for Africa?

- Maximized bird capacity with minimum land

- Compatible with automated systems for efficiency

- Hot-dip galvanized steel resists rust and wear

- Clean, dry environment reduces disease risk

- Expandable and modular, ideal for future growth

The H Type 4-Tier Layer Cage System is well-suited for medium-to-large poultry farms looking to improve productivity, reduce labor, and ensure long-term ROI in African farming conditions.

Build Your Poultry Farm with LIVI Machinery

With over 1,000 successful projects in 70+ countries, LIVI Machinery offers end-to-end poultry farming solutions, from farm design to installation. We provide customized plans for various climates and capacities, ensuring you get the most from every square meter and every bird.

📩 Email: [email protected]

📞 WhatsApp/WeChat: +86 155 3717 9350

🌐 Website: www.livimachinery.com