Efficient Battery Cage System in Poultry: 50,000-Layer Farm Project in Pakistan with H-Type 4-Tier Cages

High-Density Poultry Farming with Advanced Battery Cage System in Pakistan

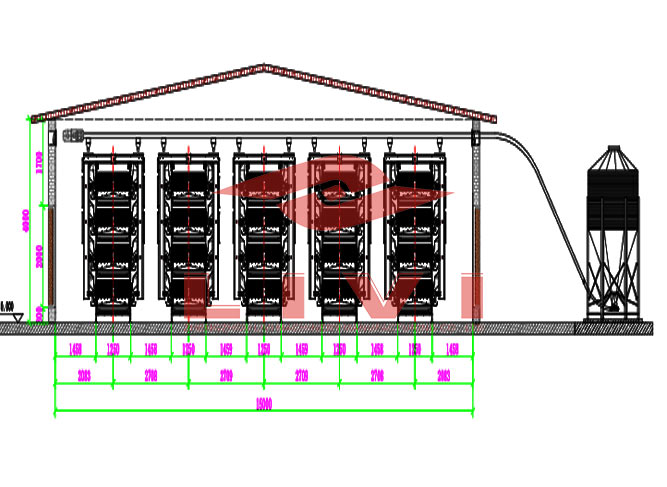

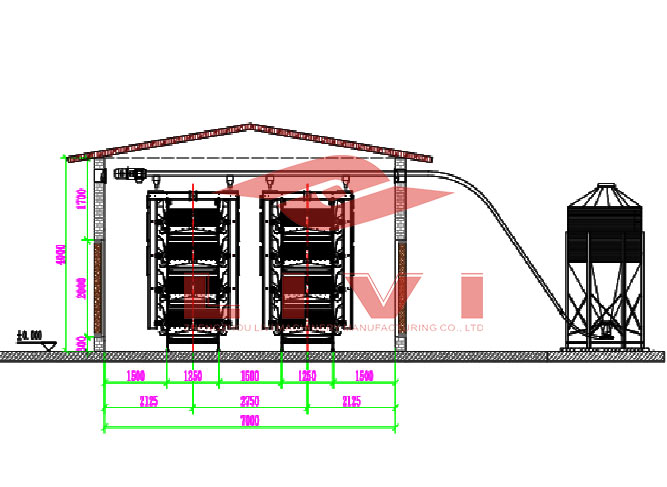

In Pakistan, where poultry farming is a vital agricultural sector, scaling up egg production efficiently is crucial. This project involved the installation of a modern battery cage system in poultry designed to house 50,000 laying hens in a single, well-organized poultry house. The farm features an H-type 4-tier layer cage system arranged in 5 columns to maximize capacity and streamline farm management.

The use of battery cage systems in poultry farming like this not only addresses the challenges of space limitation but also reduces labor intensity and improves flock health.

Project Overview

- Location: Pakistan

- Total Layers: 50,000 hens

- Cage Type: H-type 4-tier battery cages

- Cage Arrangement: Single house, 5 rows (columns)

- Number of Cage Sets: 350 sets

- Birds per Cage Set: 144 birds

- Total Capacity: 50,400 birds

- Automation: Full automation including feeding, egg collection, manure removal, and drinking system

By using H type battery cages, each holding 144 birds, the farm achieves a compact and highly efficient housing solution for 50,000 layers, all under one roof.

Why Choose Poultry Battery Cage System for This Project?

Maximize Space with 5-Column, 4-Tier Cage Layout

The H-type battery cage system uses vertical space smartly with 4 tiers, and horizontal space effectively with 5 columns, optimizing the poultry house footprint while maintaining bird welfare standards.

Durable and Corrosion-Resistant Cages

Manufactured with hot-dip galvanized steel, the cages offer excellent resistance to Pakistan’s diverse climate conditions, ensuring a lifespan of 15 to 20 years.

Integrated Full Automation for Labor Efficiency

This project includes:

- Five automatic feeding machine

- Five belt-type manure cleaning machines (one per column)

- Five egg collection machines

- Nipple drinking system with water tanks

The automation drastically cuts manual labor costs and increases operational efficiency.

Equipment List

| Equipment | Quantity | Description |

|---|---|---|

| H-Type 4-Tier Battery Cage Sets | 350 sets | 144 birds per set, total capacity 50,400 birds |

| Automatic Feeding Machine | 5 sets | Centralized feeding system across all cage rows |

| Belt Manure Cleaning Machines | 5 sets | One machine per cage column |

| Automatic Egg Collection System | 5 sets | One per column for efficient egg collection |

| Nipple Drinking System | Full set | Includes water tanks for each cage column |

| Climate Control System | Customized | Ensures stable environment inside poultry house |

Client Feedback

“The battery cage system in poultry provided by LIVI Machinery has revolutionized our production. Housing 50,000 layers in one poultry house with full automation significantly reduced our labor and improved hygiene. The durability and design of the H-type cages are ideal for Pakistan’s environment.”

— Poultry Farm Owner, Pakistan

Advantages of Using Battery Cage System in Chicken Farming

- High stocking density for large-scale farms without expanding land

- Automation-compatible design improves efficiency and reduces labor costs

- Cleaner environment through effective manure management and drinking systems

- Robust galvanized cages for long-term use in humid and variable climates

- Modular and scalable system, easy to expand or replicate

Partner with LIVI Machinery for Your Battery Cage System in Poultry

With over a decade of expertise in poultry equipment manufacturing and international project experience, LIVI Machinery delivers tailored solutions based on your farm’s scale and environment.

Contact us for a consultation to design your ideal battery cage system for optimized egg production.

📩 Email: [email protected]

📱 WhatsApp/WeChat: +86 155 3717 9350

🌐 Website: www.livimachinery.com