Battery Cage System for 20,000 Layers Poultry Project in Thailand

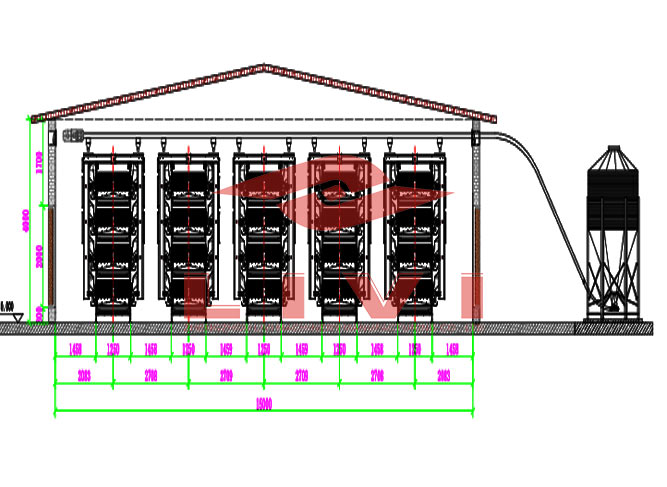

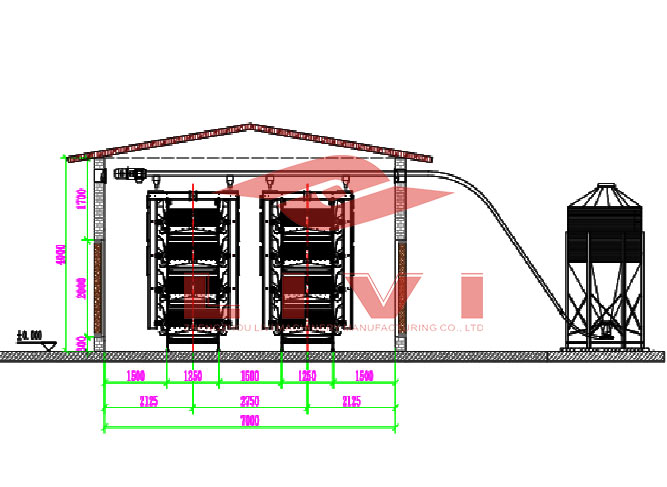

In this project, our client in Thailand invested in a fully automated battery cage system to raise 20,000 laying hens. It is aiming to reduce labor costs and optimize daily management. This poultry farm features a single chicken house equipped with 2 rows of H-type 4-tier chicken cages. A design well-suited for maximizing capacity in a limited space while ensuring bird health and egg safety.

Project Overview

The client operates a mid-scale commercial poultry business in central Thailand and needed a reliable, scalable cage system to raise 20,000 laying hens. Their main concerns included climate adaptability, manure handling efficiency, and stable egg output. Given Thailand’s hot and humid environment, proper ventilation and waste management were also crucial. After understanding the client’s farm layout and operation goals, we recommended our H-type 4-tier battery cage system for layers, featuring automatic feeding, drinking, egg collection, and manure removal systems.

Equipment Supplied

| Item | Specification | Quantity |

| H Type 4-Tier Layer Cages | 1200mm x 625mm x 480mm, 144 birds per set | 140 sets of h type chicken cage |

| Nipple Drinking System | With water pressure regulators | 2 sets |

| Automatic Feeding System | 2-row feeding machine | 2 sets |

| Manure Cleaning System | 2-row belt type | 2 sets |

| Egg Collection System | 2-row auto egg collection belt system | 2 sets |

| Frame & Installation Materials | Hot-dip galvanized steel | Included |

Note: 140 cage sets x 144 birds/set = 20,160 birds, fitting the 20,000-layers target.

Key Advantages of the Battery Cage System

This battery cage system for chickens is tailored to meet the specific challenges faced by poultry farms in Southeast Asia:

- Space Efficiency: The vertical 4-tier structure allows maximum utilization of chicken house height, fitting 20,000 layers in one house with just 2 rows.

- Labor Reduction: With automatic equipment for feeding, egg collection, and manure removal, daily operations require minimal manpower.

- Improved Hygiene: The scraper manure removal system ensures clean conditions and reduces disease risk caused by wet litter.

- Better Egg Protection: Eggs roll gently onto collection belts, minimizing breakage during transfer.

The H-type battery cage design also features strong galvanized materials that resist corrosion in humid environments, prolonging service life and lowering maintenance costs.

Client Feedback

“We are very satisfied with this battery cage system. The automated features greatly simplify our daily routine, and egg production is stable even in Thailand’s warm climate. The cage structure is strong, and cleaning is much easier now. We plan to expand our capacity using the same system next year.”

— Farm Manager, Thailand Poultry Project

Why Choose LIVI Battery Cage Systems for Chickens

LIVI has over a decade of experience providing battery cages for laying hens and full farm solutions across more than 70 countries. For this Thai project, our design team provided precise calculations, installation guidance, and system training, ensuring fast implementation and smooth operation from day one. Our battery cage systems are highly customizable based on climate, flock size, and management preferences.

Let’s Build Your Poultry Success Together

Whether you’re upgrading an existing facility or building a new egg farm, LIVI’s battery cage system offers the ideal solution for efficiency and reliability. Contact us to get a customized farm plan tailored to your capacity, land size, and local conditions.

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com