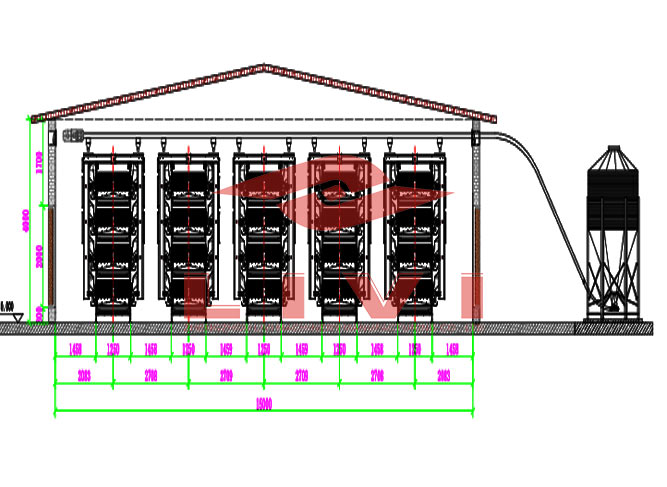

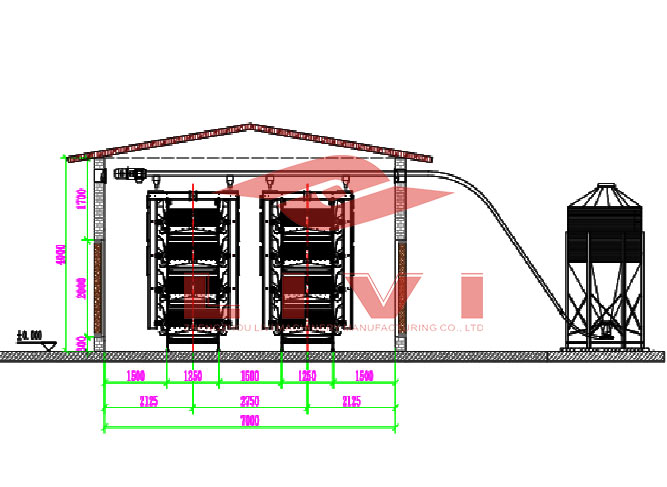

H Type Battery Cages for Layers: 30,000-Bird Poultry Project in Mexico with 3-Row H-Type 4-Tier Cage System

In 2019, a new poultry farm in Mexico selected LIVI’s H Type battery cages for layers to build their first large-scale egg production facility. The project uses a high-density H Type 4-tier layer cage system arranged in 3 rows, providing efficient housing for 30,000 laying hens. Full automation in feeding, manure removal, egg collection, and water supply helps ensure smooth, hygienic daily operations.

The client, new to poultry farming, aimed to start a large-scale farm with a reliable and efficient system to meet growing market demand. The H Type battery cage system perfectly supports these goals with its space-saving design and advanced automation.

Project Overview

Location: Mexico

Total Layers: 30,000 birds

Cage Model: H Type 4-Tier Battery Cages

Cage Layout: Single poultry house, 3 rows

Number of Cage Sets: 210 sets

Birds per Set: 144 birds

Total Capacity: 30,240 birds

Automation Included: Automatic feeding, manure cleaning, egg collection, nipple drinking system and automated environmental control systems

Equipment Supplied in This 30,000-Bird Poultry Project

| Equipment Lists | Quantity | Description |

| H-Type 4-Tier Layer Cage Sets | 210 sets | 144 birds per set, total ~30,000 birds |

| Automatic Feeding Machine | 3 sets | Feeds all rows uniformly |

| Automatic Manure Cleaning System | 3 sets | One system per cage row |

| Egg Collection Machines | 3 sets | Fully automatic egg collection per row |

| Nipple Drinking System with Water pressure regulator | Full set | Stable, clean water supply for all birds |

| Climate Control System | Customized | Fans, air inlets, and side curtains for airflow |

Why Choose H Type Battery Cages in Mexico?

Mexico’s warm climate and production scale demand poultry cages that resist corrosion and provide good ventilation. LIVI’s hot-dip galvanized H Type battery cages offer excellent durability in these conditions. The 4-tier vertical design allows high stocking density while maintaining airflow and bird welfare.

Automation reduces labor costs and improves hygiene. Gantry feeding, belt manure removal, and egg collection systems enable a small team to efficiently manage the farm. The battery cage system ensures better egg quality with less breakage and contamination.

Client Feedback

“LIVI’s H Type battery cages fit perfectly with our farm’s needs. The automated systems save time and labor, and the birds are healthier and more productive. Management is easier, and we plan to expand using this system.”

— Poultry Farm Owner, Mexico

Advantages of H Type Battery Cages for Layers

- Space-saving 4-tier vertical layout

- Corrosion-resistant hot-dip galvanized steel

- Full automation of feeding, manure cleaning, and egg collection

- Improved hygiene and disease control

- Suitable for Mexico’s climate and commercial-scale operations

Build a Modern Egg Farm with LIVI’s H Type Battery Cages

LIVI Machinery has delivered over 1,000 successful poultry cage projects worldwide, including Mexico. Our H Type battery cages combine durability, automation, and efficiency for your poultry farm’s success.

Contact Us:

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com