Automatic Battery Cage System for 30,000 Layers Poultry Project in Tanzania

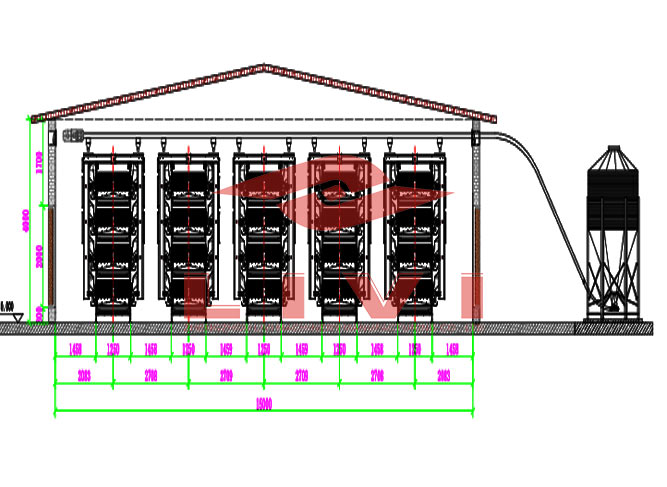

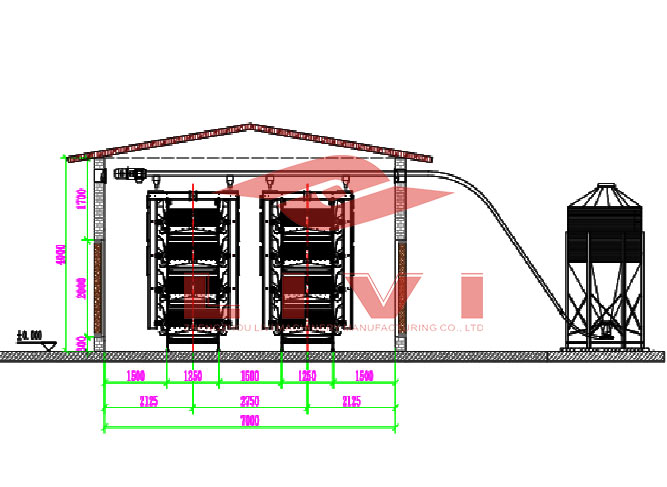

Facing increasing production pressure and rising labor costs, a commercial egg farm in Tanzania decided in 2023 to upgrade its poultry house with a fully automatic battery cage system. In this 2023 project, a large poultry farm in Tanzania adopted LIVI’s automatic battery cage system to raise 30,000 laying hens in a modernized, fully automated environment. The farm features a single-layer house with 5 rows of H-type 4-tier battery cages, maximizing capacity while ensuring cleanliness and efficiency.

Project Overview

Location: Tanzania

Total Layers: 30,000 birds

Cage Model: H-type 4-tier battery cages

Cage Layout: Single poultry house with 5 rows

Number of Cage Sets: 210 sets

Birds per Set: 144 birds

Total Capacity: 30,240 birds

Automation Included: Automatic feeding, manure cleaning, egg collection, and nipple drinking system

The farm used 210 sets of H-type 4-tier cages, each housing 144 birds, bringing total installed capacity to 30,240 layers. With a 5-row layout in a single house, the setup achieves high-density farming with efficient ventilation and workflow design.

Equipment Supplied in This Poultry Project

| Equipment Lists | Quantity | Description |

| H-Type 4-Tier Layer Cage Sets | 210 sets | 144 birds per set, total 30,240 birds |

| Automatic Feeding Machine | 5 sets | Feeds all rows uniformly |

| Automatic Manure Cleaning System | 5 sets | One system per cage row |

| Egg Collection Machines | 5 sets | Fully automatic egg collection per row |

| Nipple Drinking System with Water pressure regulator | Full set | Stable, clean water supply for all birds |

| Climate Control System | Customized | Fans, air inlets, and side curtains for airflow |

Why Choose an Automatic Battery Cage System in Tanzania?

Tanzania’s poultry farmers are increasingly shifting toward automation to solve challenges in hygiene, labor, and egg breakage. In warm and humid areas, cleanliness and ventilation are critical. LIVI’s hot-dip galvanized H-type battery cages offer superior durability, rust resistance, and a long service life under tropical conditions.

The 4-tier vertical layout and 5-row configuration enable large-scale farming within a single house. Automation simplifies daily management: feeding, egg collection, and manure cleaning are all mechanized, allowing a small team to maintain the farm efficiently. Clean water is continuously delivered through the nipple drinking system, improving bird health and egg yield.

Client Feedback

“We chose LIVI’s automatic battery cage system because it combines high capacity with easy operation. The system works very well—feeding and egg collection are automated, and we save a lot on labor. The cages are strong and easy to clean, and our egg production has been steady. We’re proud of how modern our farm looks now.”

— Poultry Farm Manager, Tanzania

Advantages of H-Type Automatic Battery Cage System

- Space-saving 5-row vertical cage layout

- Hot-dip galvanized steel for long-term durability

- Fully automated feeding, manure cleaning, and egg collection

- Enhanced sanitation and reduced disease risk

- Better egg quality due to clean handling systems

- Designed for tropical climates and large-scale operations

Build Your Poultry Farm with LIVI’s Automatic Battery Cage Solutions

LIVI Machinery has provided poultry equipment and solutions to over 70 countries worldwide. Our automatic battery cage systems are tailored to each farm’s goals, climate, and capacity needs. Whether you’re expanding or modernizing, LIVI helps your poultry business grow with confidence.

Contact Us

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com