H-Type 4-Tier Chicken Cages for 25,000 Layers in Ghana

As Ghana’s demand for commercial egg production rises, more poultry farmers are investing in efficient cage systems to boost output and improve farm hygiene. In this 2024 project, a Ghanaian poultry farm selected LIVI’s H-Type 4-Tier Chicken Cages to establish a modern facility designed to house 25,000 laying hens in a single automated chicken house.

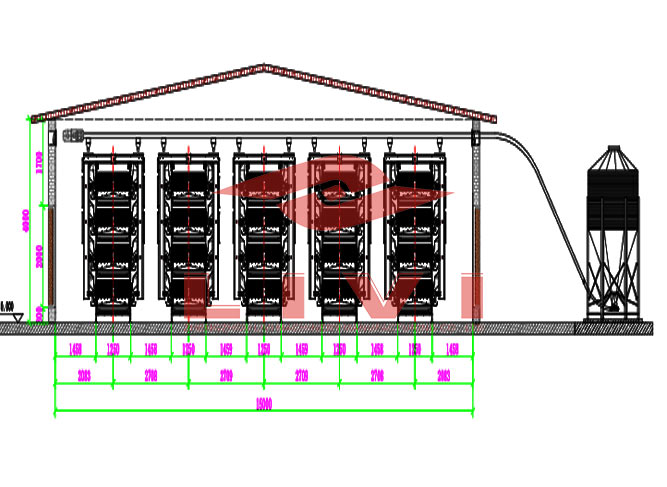

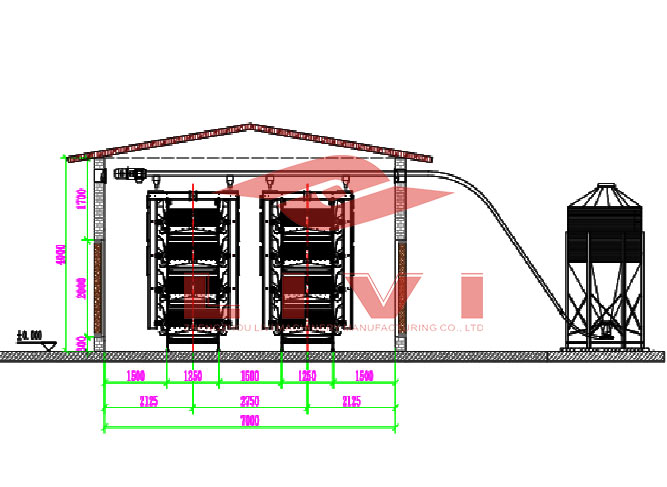

The project uses a high-density H-type battery cage system with four vertical tiers and two rows in the building. This layout optimizes available space while ensuring proper ventilation and ease of management. The system integrates automation for feeding, manure removal, egg collection, and water supply, allowing efficient daily operation with reduced manual labor.

Project Overview

Location: Ghana

Total Layers: 25,000 birds

Cage Model: H-type 4-tier battery cages

Cage Layout: Single poultry house with 2 rows

Number of Cage Sets: 174 sets

Birds per Set: 144 birds

Total Capacity: 25,056 birds

Automation Included: Automatic feeding, egg collection, manure cleaning, and nipple drinking system

Using 174 sets of H-type 4-tier cages, each housing 144 birds, the farm reaches a total capacity of 25,056 layers—perfectly matching the production scale while providing a buffer for flock management.

Equipment Supplied

| Equipment Lists | Quantity | Description |

| H-Type 4-Tier Layer Cage Sets | 174 sets | 144 birds per set, total 25,056 birds |

| Automatic Feeding Machine | 2 sets | Even feed delivery across both rows |

| Automatic Manure Cleaning System | 2 sets | One per cage row |

| Egg Collection Machines | 2 sets | Fully automatic egg collection per row |

| Nipple Drinking System with Water pressure regulator | Full set | Provides consistent and clean water to each cage |

| Climate Control System | Customized | Fans, air inlets, and side curtains for airflow |

Why Choose H-Type 4-Tier Chicken Cages in Ghana?

In Ghana’s hot and humid climate, maintaining good sanitation and ventilation is essential for healthy layer production. The H-Type 4-tier cage system is built with hot-dip galvanized steel, offering excellent corrosion resistance and a long service life under tropical conditions.

Automation greatly reduces the farm’s dependence on manual labor, which can be costly and unreliable in rural regions. The full cage system helps improve egg cleanliness, reduce breakage, and simplify bird management, making it ideal for farms aiming to scale up with confidence.

Client Feedback

“We were starting from scratch and wanted a reliable system for raising layers on a large scale. LIVI’s H-type chicken cages gave us everything—easy installation, strong materials, and full automation. Our first batch of layers is already producing steadily, and we’re very satisfied with the results.”

— Poultry Farm Owner, Ghana

Benefits of LIVI’s H-Type 4-Tier Battery Cage System

- High-density layout for maximum space utilization

- Hot-dip galvanized steel construction for tropical durability

- Automated feeding, cleaning, and egg collection for labor savings

- Improved biosecurity and cleaner egg output

- Easy to manage and scalable for future expansion

Build Your Poultry Business with LIVI’s Layer Cage Solutions

LIVI Machinery has served over 70 countries with expert poultry equipment and design services. Whether you’re starting a new farm or upgrading your current system, our H-Type 4-Tier Chicken Cages help you achieve better performance, cleaner operations, and more consistent egg production.

Contact Us

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com