Type H Battery Cage System for 50,000 Layers Chicken Farm in Nepal

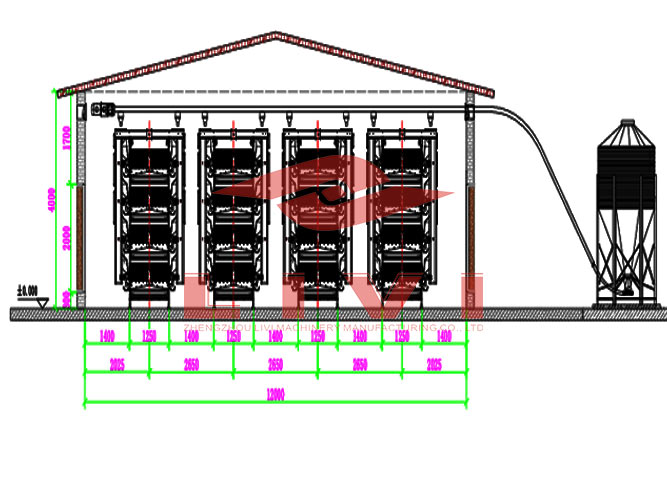

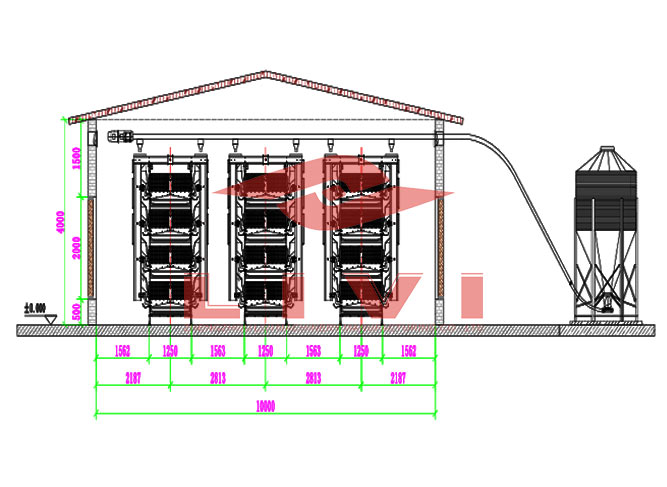

As Nepal’s commercial egg market grows to meet rising domestic consumption, large poultry farms are investing in efficient and scalable cage systems. In this 2023 project, a poultry farm in Nepal installed LIVI’s Type H battery cage system to house 50,000 layers in a single poultry house using H-type 4-tier cages in a 5-row layout.

The farm adopted a fully automated cage solution including systems for feeding, manure removal, egg collection, and water supply. This modern layout allows the farm to maximize bird density and maintain a hygienic, low-labor operation that performs reliably year-round in Nepal’s subtropical highland climate.

Project Overview

Location: Nepal

Total Layers: 50,000 birds

Cage Model: H-type 4-tier battery cages

Cage Layout: Single poultry house with 5 rows

Number of Cage Sets: 348 sets

Birds per Set: 144 birds

Total Capacity: 50,112 birds

Automation Included: Automatic feeding, egg collection, manure cleaning, and nipple drinking system

Using 348 sets of H-type 4-tier layer cages, each set housing 144 birds, the farm reaches a total installed capacity of 50,112 laying hens, meeting the client’s production target with efficiency and flexibility.

Equipment Supplied

| Equipment Lists | Quantity | Description |

| H-Type 4-Tier Layer Cage Sets | 348 sets | 144 birds per set, total 50,112 birds |

| Automatic Feeding Machine | 5 sets | Uniform feed delivery across 5 rows |

| Automatic Manure Cleaning System | 5 sets | One system per cage row |

| Egg Collection Machines | 5 sets | Fully automatic, one per row |

| Nipple Drinking System with Water pressure regulator | Full set | Provides clean and steady water |

| Climate Control System | Customized | Fans, inlets, curtain systems as needed |

Why Choose H-Type Battery Cages for Poultry Farming in Nepal?

In recent years, Nepal has seen a growing demand for local egg production, particularly in urban markets like Kathmandu and Pokhara. However, traditional open housing systems often suffer from poor waste management, disease outbreaks, and labor inefficiencies.

To establish a new, large-scale layer operation, the client needed a space-efficient, hygienic, and low-maintenance system that could operate consistently in Nepal’s mixed climate conditions. LIVI’s Type H battery cage system provided the ideal solution—with durable hot-dip galvanized materials, automated processes, and a well-organized cage layout that ensures both bird health and egg quality.

Client Feedback

“This was our first large-scale commercial farm, and we wanted a system that could support our business long-term. LIVI’s Type H battery cages are strong, well-designed, and easy to manage. The automatic feeding and egg collection made daily work much easier. We’re planning to add another house soon.”

— Poultry Farm Owner, Nepal

Advantages of the Type H Battery Cage System

- Compact, high-density layout with 4-tier, 5-row configuration

- Hot-dip galvanized construction for long-term durability

- Full automation of daily operations

- Improved hygiene and lower mortality

- Ideal for Nepal’s seasonal climate and hilly terrain

- Easy to expand as demand increases

Grow Your Poultry Farm with LIVI’s Cage Solutions

With more than 70 countries served, LIVI Machinery delivers complete poultry cage systems tailored to your location, climate, and goals. Our Type H battery cage system helps you raise layers efficiently while maintaining biosecurity and production performance.

Contact Us

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com