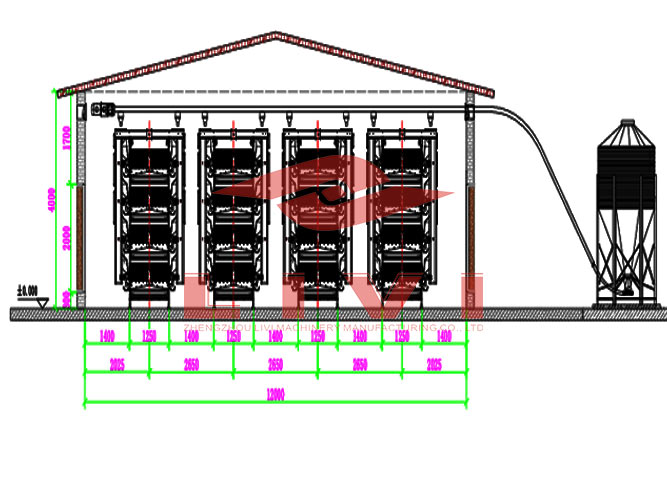

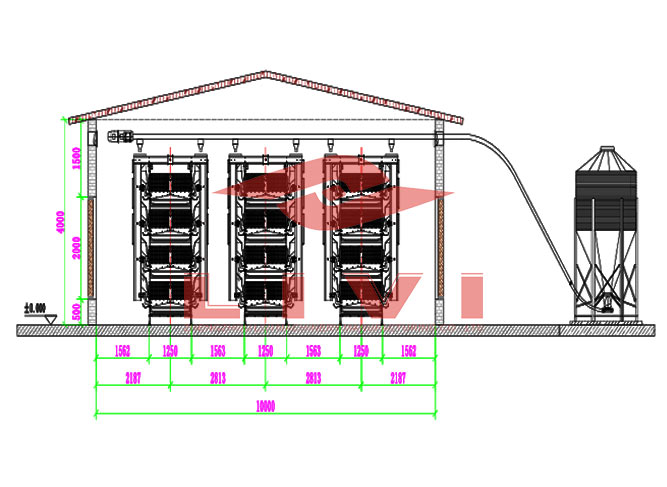

20,000-Bird Poultry Housing System in Saint Kitts and Nevis Featuring Advanced H Type Layer Cages

Project Overview

This project in Saint Kitts and Nevis is designed to accommodate 20,000 laying hens using an advanced H-Type 3-tier battery cage system within a single poultry house. The design focuses on maximizing space efficiency while ensuring optimal ventilation, bird welfare, and ease of farm management.

Client Requirements and Solutions Provided

The client required a reliable and scalable cage system capable of supporting 20,000 layers under tropical island climate conditions. Key requirements included:

- Space-efficient vertical cage design.

- Automated feeding and drinking systems to ensure bird health.

- Effective manure removal to maintain a hygienic environment.

- Robust egg collection system to streamline operations.

- Durable construction suitable for the local climate.

Our Solution:

- Advanced H-Type 3-Tier Battery Cage System: Vertical design with 3 tiers arranged for maximum space utilization.

- Nipple Drinking System with Water Tanks: Provides clean, continuous water supply.

- Gantry Feeding Machine: One set per poultry house for automated and uniform feeding.

- Belt System Manure Cleaning Machine: One unit per cage column for efficient manure removal.

- Egg Collecting Machine: One per column for easy egg collection.

This system ensures improved productivity, better bird health, and reduced labor costs.

Project Equipment List

| Equipment | Quantity | Notes |

| H-Type 3-Tier Battery Cages | Calculated for 20,000 birds | Single house, cage groups per calculation |

| Automatic Drinking System | As per cage groups | Stable water supply |

| Automatic Feeding System | As per cage columns | Automated feeding machine |

| Automatic Manure Cleaning Machine | As per cage columns | Efficient manure removal |

| Automatic Egg Collecting System | As per cage columns | Automated egg collection |

Customer Feedback

The client praised the cage system’s robustness and suitability for the island’s tropical climate, noting the following benefits:

- Improved bird health and comfort.

- Easy farm operation due to automation.

- Effective manure management, keeping the environment clean.

- Prompt professional support from LIVI Machinery.

Contact Us

For more details or custom poultry housing solutions, please contact us:

- Email: [email protected]

- WhatsApp/WeChat: +86 155 3717 9350

- Website: www.livimachinery.com

Our expert team is ready to assist with customized designs, installation, and ongoing support.