A-Type Automated Layer Cages for 20,000 Chickens Farm in Uganda

Project Overview

In 2019, Livi Machinery successfully delivered and assisted in the installation of A-Type Automated Layer Cages for a 20,000-layer poultry farm in central Uganda. The client, an experienced poultry operator looking to expand egg production while reducing operational labor, chose Livi’s fully automated A-type solution for its reliability, space efficiency, and long-term cost-effectiveness. The project marks another milestone in East Africa’s move toward modern, large-scale poultry farming.

Client Needs and Tailored Solution

The Ugandan client approached us with several specific needs:

- Housing 20,000 laying hens within a well-ventilated and compact facility

- Automating feeding, manure removal, and egg collection to reduce labor costs

- Ensuring cage durability in Uganda’s tropical climate

- Enhancing egg quality and improving bird management

After an on-site layout consultation and production goal analysis, we recommended our A-Type Automated Layer Cages in a 4-tier configuration, integrated with:

- Automatic gantry feeding system for uniform feed distribution

- Scraper manure removal system for improved hygiene and odor control

- Egg collection conveyor for fast, gentle egg gathering

- Nipple drinkers with pressure control and medication integration

This design ensured the client could manage 20,000 birds efficiently with minimal staff.

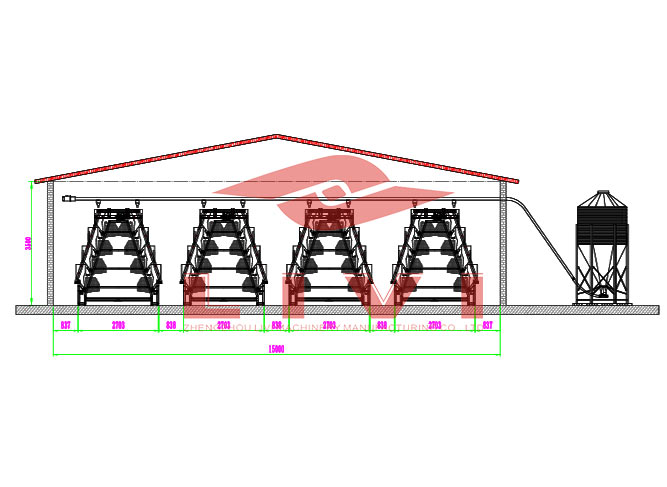

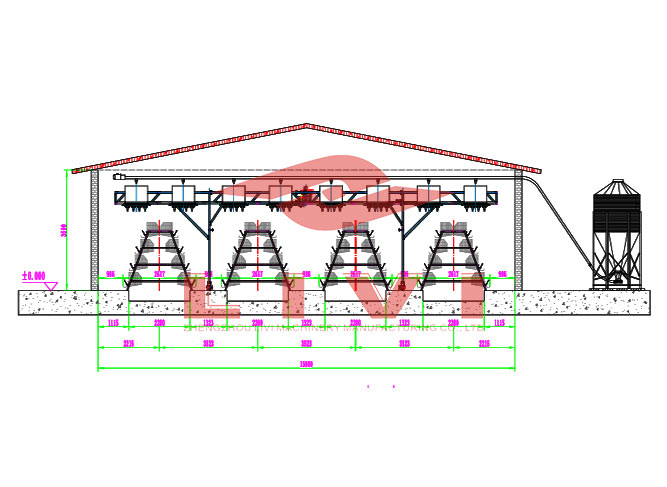

Poultry House Layout and Equipment Delivered

The layer house was constructed with a 3-row × 4-tier layout, offering high stocking density while maintaining proper ventilation and operational access.

Equipment Supplied:

- 126 sets of A-Type Automated Layer Cages (hot-dip galvanized steel)

- 1 automatic gantry feeding machine

- 1 set of Scraper manure removal system

- 2 egg collection conveyors with egg collection

- Water line system with tanks

- Spare parts package and full installation manuals

Installation and Technical Guidance

Livi Machinery provided full support throughout the project, including:

- Civil construction drawings and cage layout planning

- Remote video guidance during cage assembly

- On-site training (by local partners and remote engineers) on equipment operation, maintenance, and emergency troubleshooting

Thanks to detailed preparation and coordination, the system was installed and operational within 30 days.

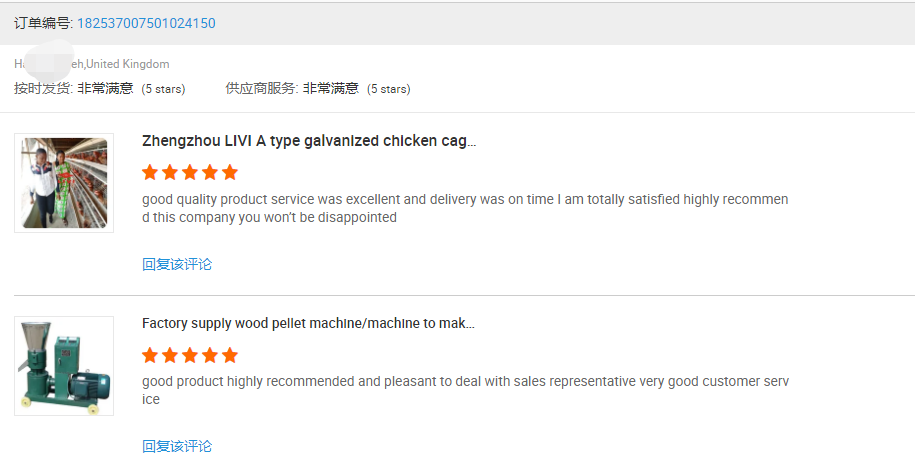

Client Feedback

The client reported excellent results shortly after launch:

- Over 95% laying rate within the first month

- Significant reduction in feed waste and labor cost

- Smooth daily egg collection with low breakage rate

- Easy cleaning and better overall hygiene in the poultry house

The farm now serves as a local model for modern poultry farming using A-Type Automated Layer Cages, and the client has expressed intent to double the farm size using Livi equipment.

Why Choose Livi’s A-Type Automated Layer Cages?

Livi Machinery’s A-Type Automated Layer Cages are ideal for poultry farms seeking:

- Large-scale egg production in compact space

- Durable, corrosion-resistant cage systems

- Full automation of feeding, cleaning, and egg collection

- Professional planning and after-sales support

With installations in over 70 countries, Livi helps poultry farmers worldwide upgrade to smarter, more productive operations.