A Type Chicken Cages for 10,000 Layers Farm in Zimbabwe

Project Introduction

In March 2025, Livi Machinery successfully supported the development of a commercial egg production farm in Zimbabwe by supplying a complete set of A Type Chicken Cages for Layers. The client, located in Mashonaland West Province, aimed to expand their laying hen capacity to 10,000 birds while ensuring operational efficiency, durability, and reduced labor costs. After evaluating the farm’s needs and structure, Livi provided a tailored A-type cage system with semi-automatic functionality and full installation support.

Client Objectives and Our Solution

The Zimbabwean client was looking to:

- House 10,000 layers in a well-ventilated and hygienic environment

- Improve feed conversion rate and egg production efficiency

- Minimize daily labor for feeding and cleaning

- Use a proven, long-lasting cage system adaptable to local climate

Based on these needs, Livi Machinery recommended a 4-tier A Type Chicken Cages for Layers system with the following components:

- High-quality hot-dip galvanized A-type layers cages

- Semi-automatic feeding machine

- Belt-type automatic manure removal system

- Nipple drinking lines with water tanks

This configuration balances automation and cost control, helping the client grow sustainably.

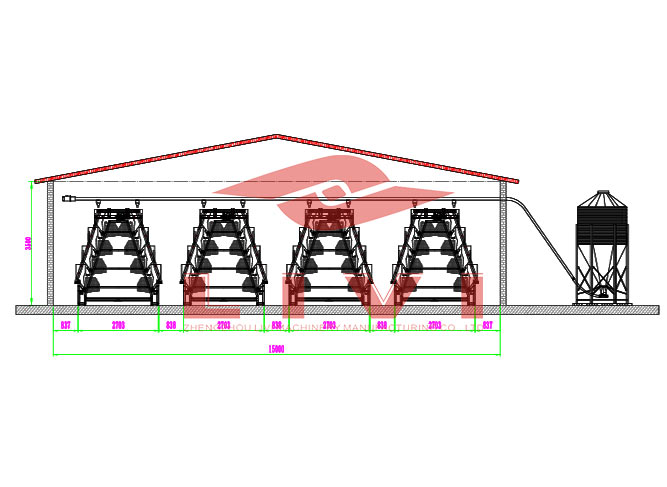

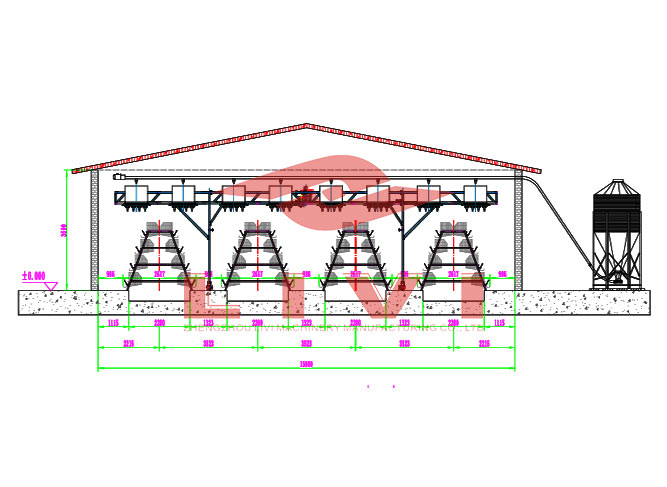

Farm Design and Equipment Configuration

The chicken house was designed with a 2-row × 32-unit structure, housing roughly 5,120 layers per row. The layout ensured optimal ventilation and allowed for natural light exposure while simplifying feeding and manure removal operations.

Supplied Equipment Includes:

- 64 sets of A Type 4-tier layer cages

- 1 semi-automatic feeding machine

- 2 automatic manure removal machines with belts

- Complete drinking system with PVC pipes and filters

- House layout design and construction guidance

- Spare parts and technical manuals

Installation and Technical Support

Although the installation was locally managed, Livi provided full engineering support via online consultation, 3D layout drawings, and detailed video instructions. The local team successfully completed the setup within three weeks. Our technical support team also trained farmworkers on daily operation and maintenance of the A Type Chicken Cages for Layers system.

Client Feedback

The client was highly satisfied with the project’s results. The cages demonstrated excellent ventilation, solid construction, and ease of cleaning. Daily egg collection became more efficient, and the mortality rate dropped significantly due to improved bird management. The client has already recommended Livi Machinery to other poultry farmers in the region.

Why Choose Livi’s A Type Chicken Cages for Layers?

Livi Machinery specializes in high-quality poultry cage systems for global markets. Our A Type Chicken Cages for Layers offer:

- Compact design ideal for medium to large-scale farms

- Long service life with anti-rust galvanized materials

- Reduced feed waste and improved hygiene

- Scalable configurations with automation options

Whether you’re raising 5,000 or 50,000 layers, Livi provides customized solutions backed by expert support.