A-Type Chicken Cages for 10,000 Layers Project in Ghana

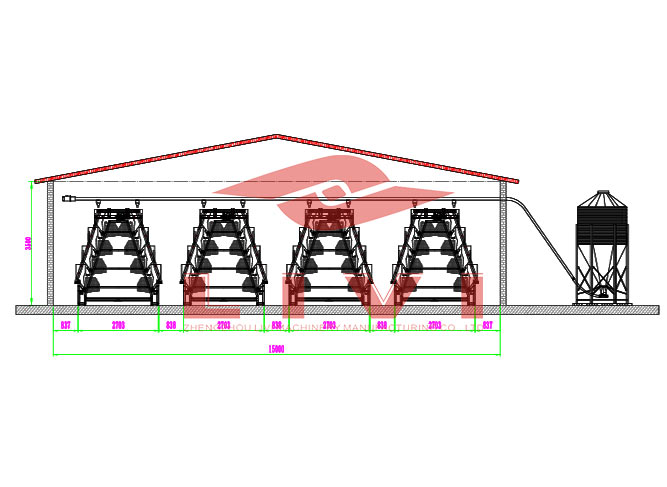

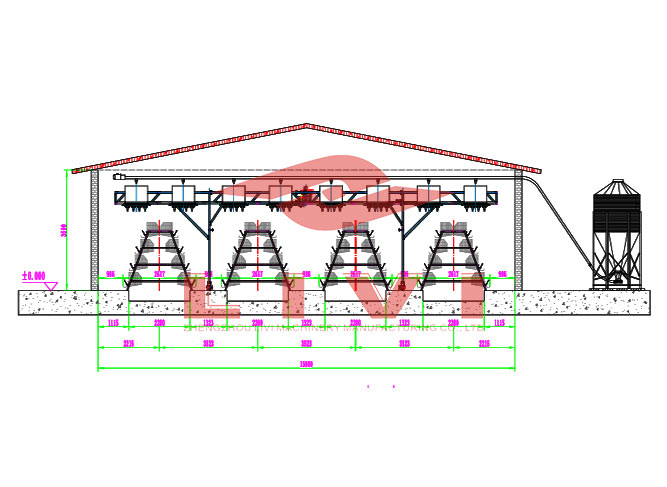

This project is a 10,000-bird egg production farm with A-type layers cages, implemented in 2020 in Tema, Ghana. The farm adopts our A-type chicken cages for layers in a 4-tier, 5-door configuration. Through a 2-row layout design equipped with fully automated feeding, manure cleaning systems, the farm achieves highly egg production.

Project Overview:

Chicken Shed Type: Open Type Chicken Shed

Chicken Shed Size: 68*8m

Client Background:

The client is a large-scale poultry farmer in Ghana looking to modernize their egg production facilities. With several years of experience in poultry farming, the client aims to increase egg yield efficiency and improve flock management through automation and scientifically designed housing.

Core Requirements:

Housing for 10,000 laying hens with sufficient space and ventilation

High-quality A-Type layer cages with 4 tiers to maximize space utilization

Automated feeding and watering systems for better resource management

Efficient manure removal system to maintain cleanliness and reduce labor

Durable, corrosion-resistant materials suitable for Ghana’s tropical climate

A layout design that ensures good ventilation, lighting, and easy maintenance

Local installation support and staff training for smooth operation

Our Solution: A-type layer cage system for 10240 layers in Ghana

We provided a customized A-Type layer cage system designed specifically for the client’s capacity and environmental conditions. The 4-tier cages offer a compact footprint while ensuring hens have enough space to live comfortably and lay efficiently. Our solution includes:

- Fully galvanized steel cages with anti-rust coating for longevity

- Automatic feeding troughs and nipple drinkers integrated within the cages

- A mechanized manure scraper system installed under each cage row for timely waste removal

- Ventilation planning with shed width limited to 15 meters to optimize airflow

- Professional layout design with options for 2, 3, or 4 cage rows to suit the shed size

- On-site installation and technical training provided by our experienced local team

- Ongoing support for maintenance and operation to ensure project success

This system significantly improves the client’s egg production efficiency, reduces manual labor, and enhances overall poultry health, positioning them well for expanding their business in Ghana’s growing poultry market.