A-Type Chicken Cages for 5,000 Layers & 5,000 Pullets Poultry Farm in Liberia

Project Overview

In Mar 2025, Livi Machinery provided cage equipment for a poultry project in Liberia, which includes two separate chicken houses: one for 5,000 laying hens and the other for 5,000 pullets. The goal was to build a basic yet efficient production line from pullet rearing to egg laying, using simple and durable systems suitable for local conditions.

Solution and Equipment Supplied

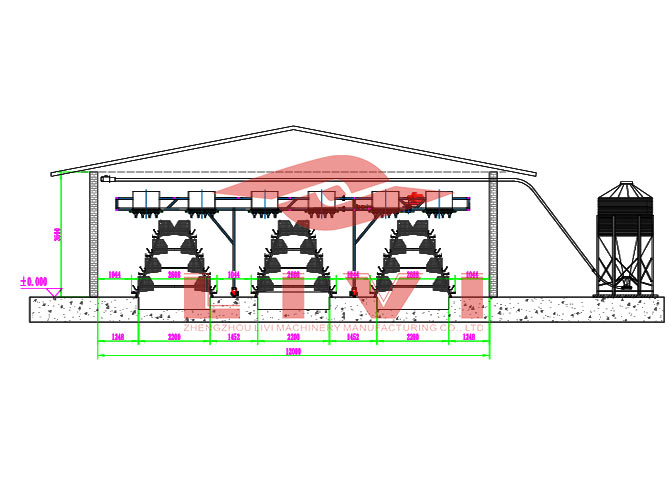

For the layer house, Livi supplied:

- 32 sets of A-Type Layer Chicken Cages, 4-tier

- Cage dimensions: 195 × 45 × 41 cm

- Layout: 2 rows × 16 sets per row

- Total birds: 5,120 layers

- Drinking system: Nipple drinking system with water tanks

- Feeding and manure handling: Manual

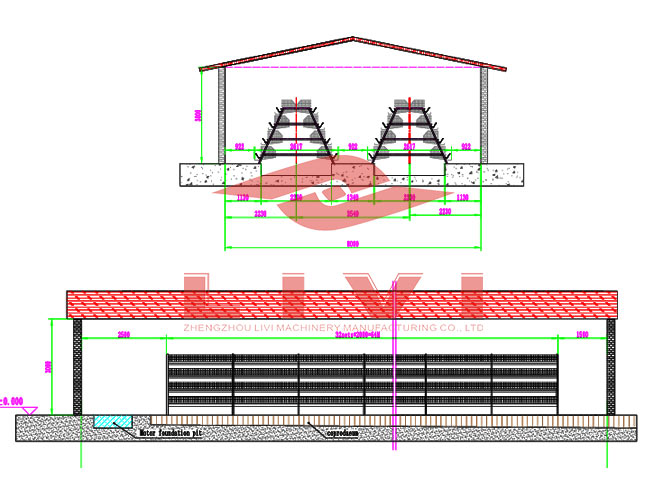

For the pullet house, Livi supplied:

- A-Type Brooder Cages, suitable for early-stage pullet rearing

- Simple layout adapted to local shed size

- Manual feeding and cleaning systems

The entire project was configured without automatic feeding or manure removal systems, prioritizing cost-efficiency and hands-on control for local farm workers.

Why Choose Livi’s A-Type Chicken Cages?

Livi’s A-Type Chicken Cages are built for flexibility, especially for small to medium-scale farms in Africa. Whether raising layers or pullets, Livi provides:

- Hot-dip galvanized cages with long service life

- Simple manual operation suited for local labor conditions

- Full-farm planning support and layout optimization

- Practical solutions for staged poultry growth