A Type Layer Chicken Cages for 15,000 Birds Farm in South Africa

Project Overview

In early 2024, Livi Machinery completed a large-scale poultry equipment supply project for a commercial egg farm in the Free State province of South Africa. The farm was expanding to a capacity of 15,000 laying hens, and the client was in need of a reliable, high-yield solution. Based on local environmental factors, space planning, and production goals, Livi delivered a fully configured system using A Type Layer Chicken Cages, paired with semi-automatic equipment to ensure efficiency and ease of use.

Client Requirements and Livi’s Tailored Solution

The South African poultry farmer had several key requirements:

- Efficient housing for 15,000 layers in a well-ventilated house

- Long-lasting cages resistant to corrosion and wear

- Cost-effective feeding and manure removal systems

- Improved egg hygiene and ease of daily management

To meet these goals, Livi Machinery designed a poultry house layout using A Type Layer Chicken Cages in a 4-tier configuration with three rows. The cage system was integrated with:

- Galvanized A-type cages with strong frame and anti-rust coating

- Semi-automatic feeding trolleys for uniform feed distribution

- Belt-type manure removal system for cleaner environment

- Nipple drinkers with water pressure regulators and filters

- Egg collection trays positioned for easy gathering and minimal breakage

This configuration ensured optimal production while remaining affordable and simple to operate.

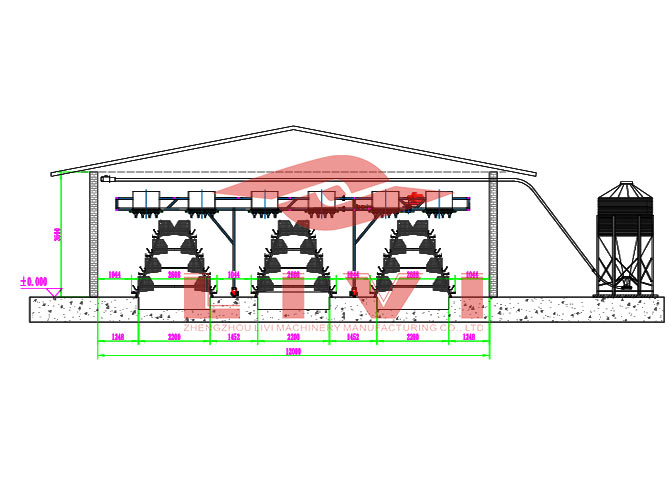

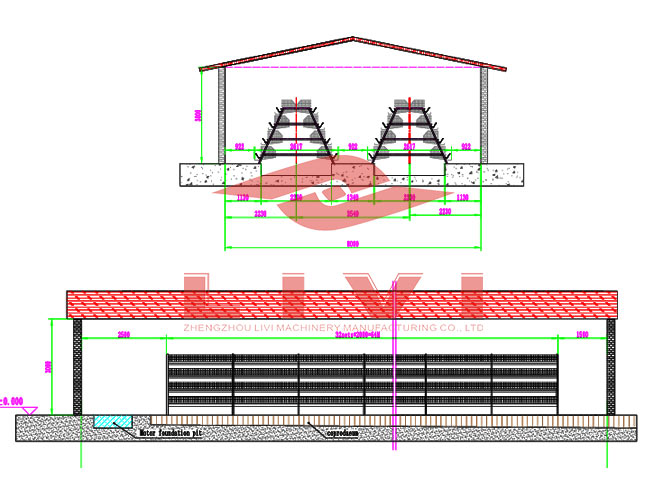

Farm Layout and Equipment Details

The poultry house measured approximately 75 meters long × 12 meters wide, following Livi’s recommended dimensions to ensure proper ventilation. The internal layout allowed for easy access to each cage unit, maintenance space, and smooth manure management.

Supplied Equipment Included:

- 30 sets of A Type 4-tier layer chicken cages

- 1 set of automatic gantry feeding machine

- Scraper manure cleaning system

- Drinking system with mainline water tank and distribution pipes

- Installation manuals, layout blueprints, and spare parts

Installation and On-Site Training

While the client had experience with smaller-scale layer operations, this was their first transition to a semi-automated cage system. Livi provided:

- Detailed construction and installation drawings

- Remote guidance via video and messaging apps

- Post-installation training on cage management, feeding schedules, and manure removal

The full installation was completed within four weeks, and the farm was fully operational shortly after.

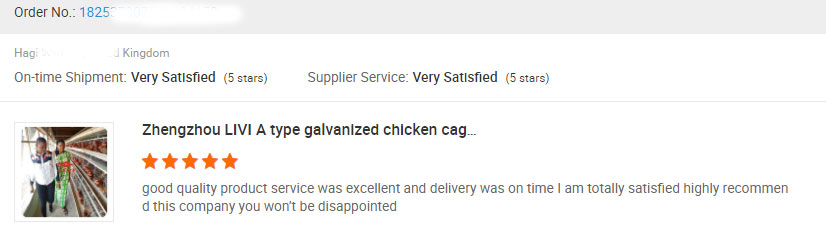

Customer Feedback

The client reported excellent performance from the A Type Layer Chicken Cages, noting:

- Improved egg cleanliness and shell quality

- Easier bird management with significantly reduced mortality

- Cleaner house environment with efficient manure handling

- Overall time savings in daily operations

They praised Livi’s timely delivery, responsive service, and professional guidance. Plans for future expansion to 30,000 birds are already under discussion.

Why Choose Livi’s A Type Layer Chicken Cages?

Livi Machinery has over 12 years of experience in poultry equipment manufacturing and export. Our A Type Layer Chicken Cages are trusted by farmers across Africa due to their:

- Hot-dip galvanized anti-corrosion materials

- Space-efficient, stable cage structures

- Optional automation upgrades

- Full technical support and one-stop service from layout to installation

Whether you’re starting or expanding a farm, we help you build for success.