A-type Layers Cages for 20,000 Chickens Project in Zambia

Project Overview

In early 2025, Livi Machinery successfully delivered and installed a large-scale A-type Layers Cages system for a 20,000 laying hens poultry farm in Zambia. The client, an experienced poultry farmer expanding their operations, needed a high-efficiency, space-saving solution that ensures excellent egg production and ease of management. After thorough consultation and farm layout planning, we customized a full set of A-type layer cages along with automatic poultry equipment.

Client Requirements and Customized Solution

The Zambian client emphasized the need for:

- Housing 20,000 laying hens in a well-ventilated, easy-to-clean environment

- Automatic feeding and manure removal to reduce labor costs

- Efficient egg collection system to ensure minimal egg breakage

- Long-lasting cages with rust-resistant materials suitable for local climate conditions

To meet these needs, we recommended our proven A-type Layers Cages system in a 4-tier design, combined with:

- Automatic feeding machine

- Automatic manure removal system

- Egg collection conveyor

- Water nipple drinkers with pressure regulators

This comprehensive setup ensured the client’s farm achieved high production efficiency with reduced daily labor.

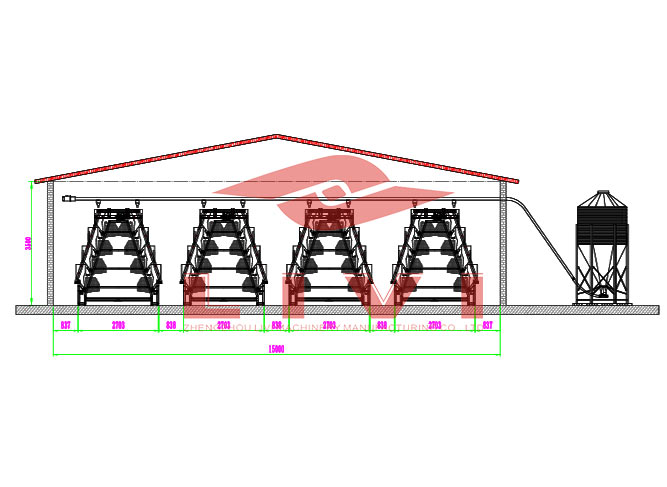

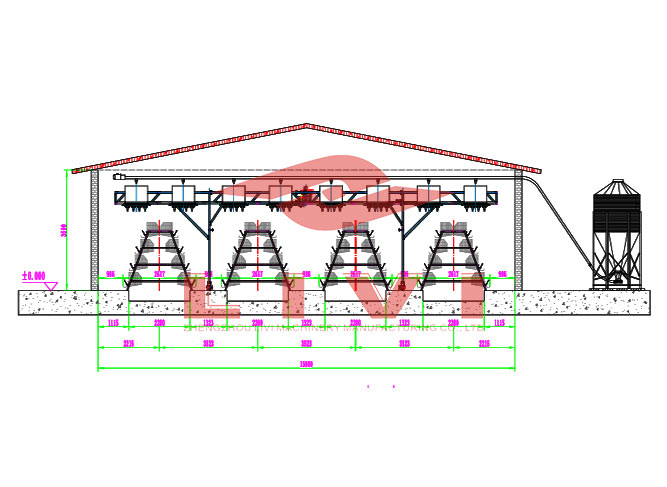

Farm Layout and Equipment List

The 20,000-bird layer project used a 4-row × 33-unit house structure, housing 5,280 birds per row. The poultry house size was carefully planned to not exceed 15 meters in width, 70 meters in length, ensuring optimal airflow and ventilation.

Equipment Supplied:

- A-type 4-tier layer cages (132 sets)

- Automatic gantry feeding system

- Belt-type manure cleaning system

- Egg collection system with side conveyor

- Drinking system with water tanks

- Installation tools and technical manuals

Installation and Local Support

Installation and Local Support

The Livi installation team provided detailed layout drawings in advance and dispatched experienced technicians to Zambia to supervise and assist in the installation. With the help of local labor, the entire system was assembled within 1 month. The client also received training on equipment maintenance and daily management of layer hens.

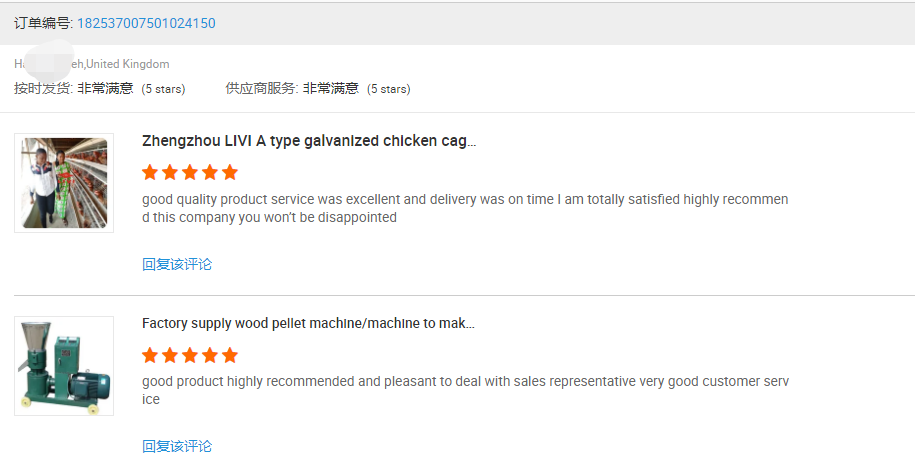

Customer Feedback

The client expressed high satisfaction with the project, especially with the cage quality, feed efficiency, and manure removal system. The A-type Layers Cages performed beyond expectations in terms of space utilization, hen welfare, and daily egg collection efficiency. The client is now planning a second phase expansion and has chosen Livi Machinery again for future cooperation.

What Livi Machinery Can Do for You

Whether you are starting a new poultry farm or upgrading an existing one, Livi Machinery offers full-service solutions with A-type chickens cages for layers, customized designs, and on-site installation support. We have over 12 years of experience and have delivered poultry cage systems to more than 70 countries. Our mission is to help poultry farmers achieve long-term profitability with efficient, durable, and automated equipment.