A Type Poultry Battery Cage

Breeds: layers, and baby chicks

Rearing Quantity / House: 5,000-30,000 birds

Service life: 15-20 years

Warranty period: 3 years

Material: International Q235 steel, hot-dip galvanized.

Certificate: ISO9001, CE, SONCAP, PVOC

Product Introduction

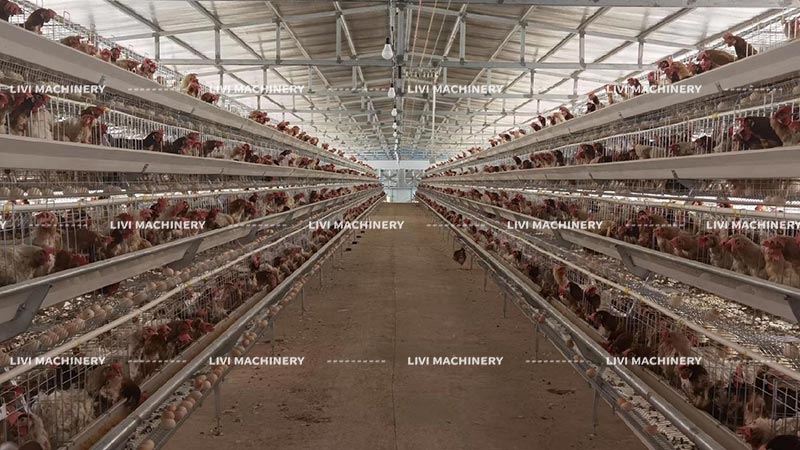

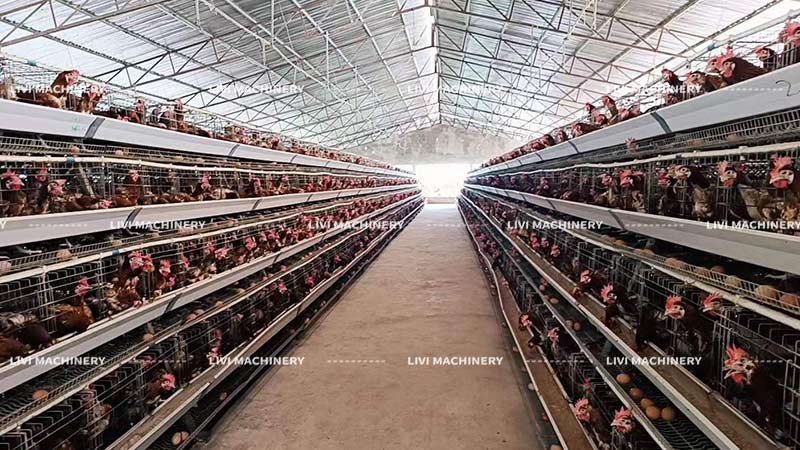

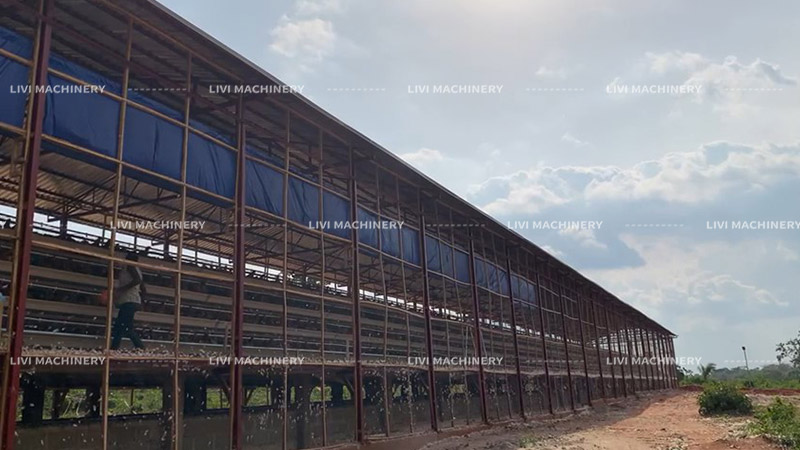

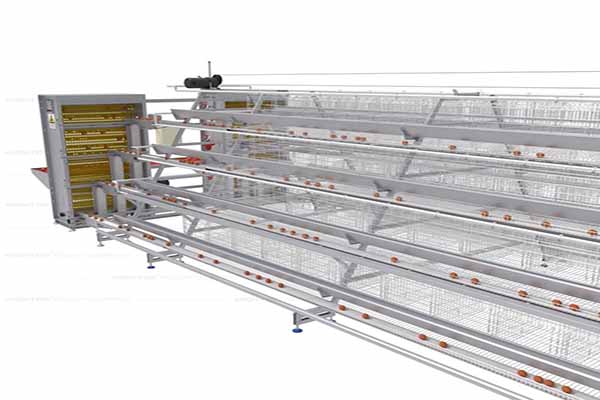

A-Type Poultry Battery Cage is a cost-effective cage system designed for medium layer chicken farms. With a tiered structure design, this poultry cage system maximizes the use of space while ensuring optimal comfort and productivity for your poultry farms. It is suitable for open and closed chicken houses and is widely used in farms across Africa, Southeast Asia, and Latin America.

Application: Layer chickens & Baby chicks

Capacity Range: 5,000–30,000 birds per house

Material: Hot-dip galvanized steel, anti-corrosion and durable up to 15–20 years

Types: A-type layer cages, A-type baby chick cages/brooder cages

Optional Automatic Equipment for A-Type Poultry Cages

- ✅Automatic drinking system

- ✅Automatic feeding system

- ✅Automatic manure cleaning system

- ✅Automatic egg-collection system (for layer cages)

Technical Parameters

| Model | Type | Bird Use | Tier Options | Cage Size (mm) | Capacity / Unit |

| A-195 | Layer Cages | Laying hens | 3-4 tiers | 1950*350*380 1950*450*410 | 90/96/120/160 |

| AP-195 | Brooder Cages | baby chicks | 3-4 tiers | 1950*500*350 | 180/240 birds |

We supply poultry farmers with One-on-one customized poultry house design and quotations based on your breeding volume or chicken house size.

Features of A Type Poultry Battery Cage

- ✅ Quality Material : Hot-dip galvanized steel for 15-20 years long-lasting durability

- ✅ High Stocking Density: 3–4 tiers design allows space-saving layouts and optimized land usage

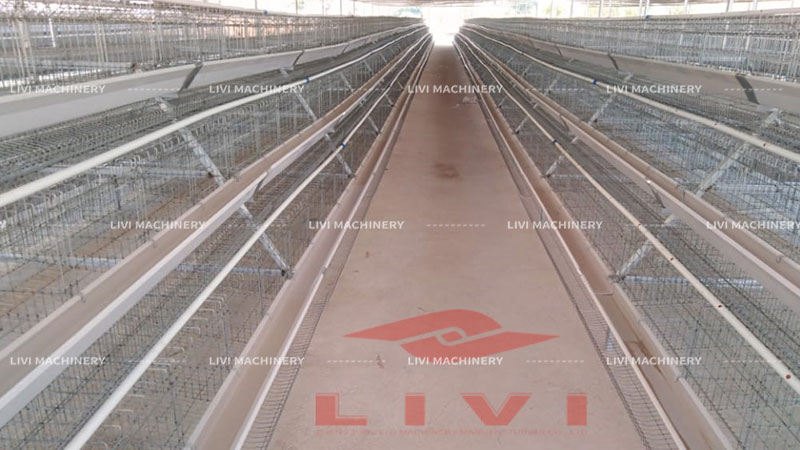

- ✅ Easy Maintenance: Simple A-type design allows for quick assembly, and repairs

- ✅ Reliable Drinking System: Nipple drinkers with water tanks provide hygienic, automatic hydration

- ✅ Customized Layout: Available in 2–4 rows per house, with flexible capacity planning

- ✅ Application: both open and closed chicken houses

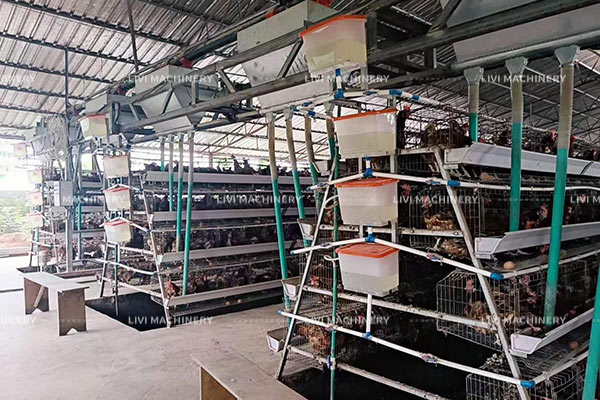

Project Cases

📍 20,000 Layers in Nigeria – 4-Tier A-Type Layer Cages

📍 15,000 Layers in Tanzania– A-Type Chicken Cages

📍 20,000 Layers in Zambia – Auto A-Type Layer Cage System

What Our Customers Say

“LIVI’s A-type cages helped me double my layer capacity with the same space. The support team was very professional.”

— Mr. Isaac, Poultry Farm Owner, Nigeria

“We chose LIVI because of their quality and experience. The cages are durable, and the egg breakage rate is very low.”

— Ms. Maria, Layer Farmer, Tanzania

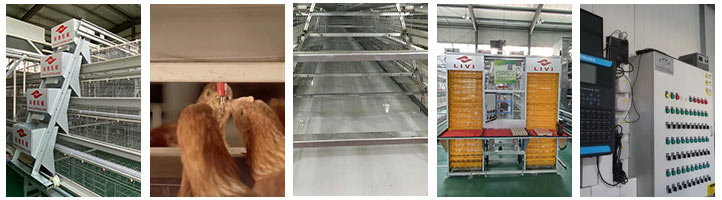

Testing of High quality A Type layer Battery Cage

A Type Layer Battery Cage

The bottom net of the cage is tilted to facilitate egg collection.

Tensile test of cage mesh, can withstand 500N tensile force.

Push-pull cage door for laying hens.

Cage load test: can withstand the weight of 3 adults.

Why Choose LIVI A-Type Poultry Battery Cage System

- ✅ Over 12 Years of Industry Experience

- ✅ Serving 70+ Countries with 1000+ Global Projects

- ✅ One-Stop Poultry Farm Solution – From layout design to equipment delivery and local installation

- ✅ Fast Production & Delivery – Optimized supply chain for rapid export

- ✅ Customized Solutions – Designs tailored for different climate zones and farm sizes

- ✅ 24/7 Customer Support – Technical assistance and training after-sales