Automated Battery Cage System for 30,000 Layers Poultry Farm Project in Senegal

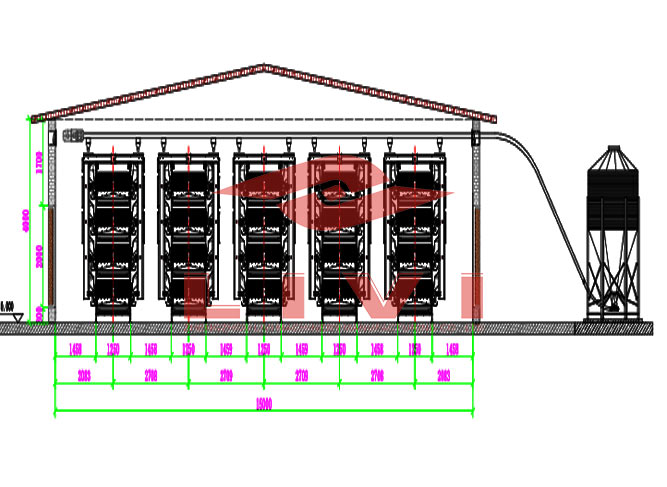

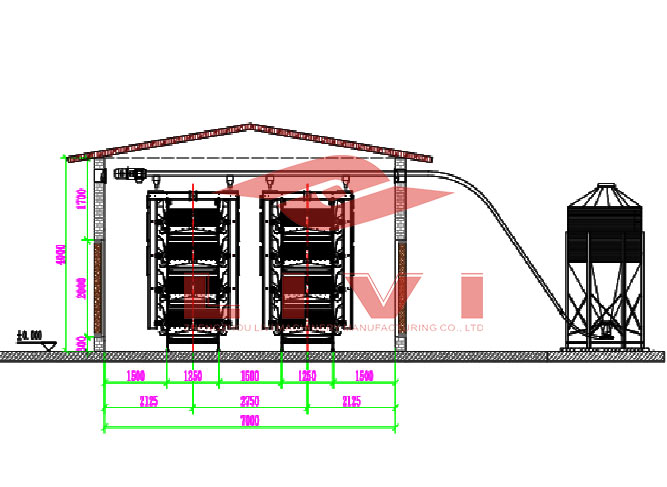

In this 2025 project, a commercial poultry farm in Senegal installed LIVI’s automated battery cage system to raise 30,000 laying hens in a single house. The farm adopted a 3-row layout of H-type 4-tier cages, integrating full automation for feeding, manure cleaning, egg collection, and drinking water supply. This high-density poultry solution delivers reliable performance and is well suited for large-scale layer operations.

The farm made this investment after facing increasing operational pressure due to labor shortages, inconsistent egg quality, and the challenges of maintaining hygiene in a humid tropical climate. By upgrading to an automated system, the farm aimed to stabilize production, reduce disease risks, and simplify day-to-day management with minimal human intervention.

Project Overview

Location: Senegal

Total Layers: 30,000 birds

Cage Model: H-type 4-tier battery cages

Cage Layout: Single poultry house with 3 rows

Number of Cage Sets: 208 sets

Birds per Set: 144 birds

Total Capacity: 29,952 birds

Automation Included: Automatic feeding, manure cleaning, egg collection, and nipple drinking system

By using 208 sets of H-type 4-tier battery cages, each set accommodating 144 birds, the farm reaches nearly 30,000 layers capacity. The 3-row layout allows optimal space usage while keeping the environment clean and well ventilated.

Equipment Supplied in This Poultry Farm

| Equipment Lists | Quantity | Description |

| H-Type 4-Tier Layer Cage Sets | 208 sets | 144 birds per set, total 29,952 layers |

| Automatic Feeding Machine | 3 sets | Even feed distribution across all rows |

| Automatic Manure Cleaning System | 3 sets | One for each cage row |

| Egg Collection Machines | 3 sets | Fully automated, per cage row |

| Nipple Drinking System with Water pressure regulator | Full set | Stable water supply throughout the house |

| Climate Control System | Customized | Fans, air inlets, curtains tailored for tropical climate |

Why Choose an Automated Battery Cage System in Senegal?

Senegal’s tropical climate demands poultry housing solutions that balance high production density with good airflow and hygiene. The hot-dip galvanized H-type battery cages offer durability against rust and corrosion. Their vertical 4-tier stacking maximizes bird capacity while maintaining sufficient ventilation.

Automation is vital in this farm to reduce labor and maintain consistent feeding, cleaning, and egg collection. The gantry feeding system ensures precise feed distribution, while belt manure removal and automatic egg collection reduce manual workload and contamination risks. This battery cage system not only enhances operational efficiency but also improves egg quality and bird health.

Client Feedback

“We are very satisfied with LIVI’s automated battery cage system. It perfectly fits our need for a scalable, reliable poultry farm solution. The automation has reduced our labor costs and improved overall farm hygiene. Egg production has become more consistent, and workers find the system easy to manage. We plan to expand with LIVI’s solutions in the near future.”

— Poultry Farm Owner, Senegal

Advantages of H-Type Automated Battery Cage System

- High-density, space-saving design

- Durable hot-dip galvanized cages for tropical use

- Fully automated feeding, manure cleaning, and egg collection

- Improved farm hygiene and disease control

- Efficient water supply with nipple drinking system

- Easy management and scalability for future expansion

Build Your Poultry Farm with LIVI’s Automated Battery Cage Systems

With extensive experience serving over 70 countries and thousands of poultry farms worldwide, LIVI Machinery offers professional, customizable solutions to meet your farm’s specific needs. Our automated battery cage systems combine quality, efficiency, and innovation to help you maximize egg production while minimizing labor and maintenance.

Contact Us

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com