Automated Chicken Battery Cage System for 100,000 Layers Poultry Project in China

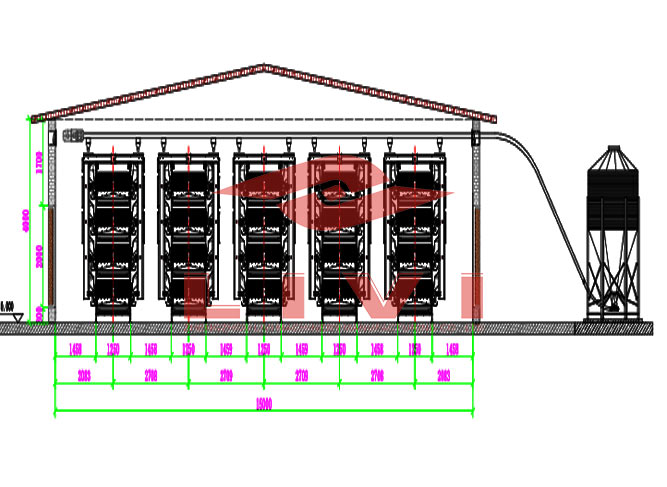

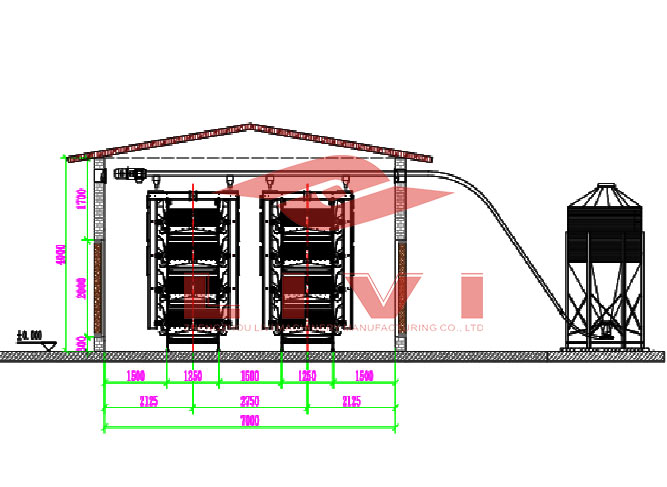

With China’s large-scale egg farms rapidly adopting automation, this 2023 project showcases how modern poultry operations are achieving high-density, low-labor production. A commercial poultry farm in China selected LIVI’s automated chicken battery cage system to raise 100,000 laying hens within a single poultry house using H-type 8-tier cages in a 5-row layout.

This project represents one of the densest cage configurations available, utilizing vertical space with 8 tiers of cages while integrating full automation for feeding, egg collection, manure removal, and drinking. The farm benefits from increased capacity, improved hygiene, and reduced labor costs.

Project Overview

Location: China

Total Layers: 100,000 birds

Cage Model: H-type 8-tier battery cages

Cage Layout: Single poultry house with 5 rows

Number of Cage Sets: 348 sets

Birds per Set: 288 birds

Total Capacity: 100,224 birds

Automation Included: Automatic feeding, manure cleaning, egg collection, and nipple drinking system

The farm uses 348 sets of H-type 8-tier layer cages, each holding 288 birds, reaching a total installed capacity of 100,224 birds—meeting the farm’s production goals with precision and efficiency.

Equipment Supplied

| Equipment Lists | Quantity | Description |

| H-Type 8-Tier Layer Cage Sets | 348 sets | 288 birds per set, total 100,224 birds |

| Automatic Feeding Machine | 5 sets | Feeds all rows uniformly |

| Automatic Manure Cleaning System | 5 sets | One system per cage row |

| Egg Collection Machines | 5 sets | Fully automatic egg collection per row |

| Nipple Drinking System with Water pressure regulator | Full set | Stable, clean water supply for all birds |

| Climate Control System | Customized | Fans, air inlets, and side curtains for airflow |

Why Choose an Automated Battery Cage System in China?

Large-scale poultry farms in China often face challenges related to land use, labor shortages, and biosecurity. The H-type 8-tier system maximizes vertical space usage, making it possible to house more layers per square meter while maintaining proper airflow and sanitation.

Automation greatly reduces manual workload, enabling the farm to manage 100,000 birds efficiently with minimal staff. In addition, automated feeding and manure systems help control feed wastage and maintain a clean environment, improving overall egg quality and production stability.

Client Feedback

“We were looking for a high-capacity cage system with full automation for our new facility. LIVI’s 8-tier battery cages allowed us to raise 100,000 hens in a single house without compromising hygiene or efficiency. The cages are well-made and the support from LIVI’s team was excellent from planning to installation.”

— Poultry Farm Manager, China

Benefits of LIVI’s H-Type 8-Tier Automated Chicken Battery Cage System

- Ultra-high density: 8-tier, 5-row layout for maximum capacity

- Hot-dip galvanized materials for long service life

- Full automation cuts labor costs and improves management

- Excellent ventilation and waste removal ensure clean environment

- Gentle egg handling system reduces breakage and contamination

- Ideal for large-scale, high-efficiency egg farms

Build Your High-Capacity Poultry Farm with LIVI

LIVI Machinery offers complete automated cage systems tailored for both new and expanding poultry farms. Our automated chicken battery cage systems are trusted in over 70 countries, helping producers like you improve yield, reduce labor, and scale efficiently.

Contact Us

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com