Automatic A-type Layer Cage System for 20,000 Chickens in Uganda

Project Background

In May 2025, a Ugandan poultry farm located near Kampala partnered with Livi Machinery to upgrade their layer chicken facility to a fully automated system. The goal was to expand their capacity to 20,000 birds while minimizing labor and maximizing efficiency. Based on the farm’s climate conditions, building size, and operational goals, we recommended the Automatic A-type Layer Cage System, known for its durability, space optimization, and seamless automation.

Client Needs and Solution Provided

The client sought a modernized cage system that would allow:

- Housing 20,000 laying hens with minimal manual labor

- Automatic feeding and manure removal to reduce workload

- Smooth egg collection with minimal breakage

- Durable cages that withstand Uganda’s humid and warm climate

To meet these requirements, we provided a complete Automatic A-type Layer Cage System, which included:

- A-type 4-tier hot-dip galvanized cages

- Automatic feeding machine (gantry type)

- Belt conveyor-type manure cleaning system

- Semi-automatic egg collection system

- Nipple drinking system with pressure regulators and water tanks

- Ventilation fans and environmental control units

This integrated system significantly reduced the farm’s dependency on labor while improving egg output and cleanliness.

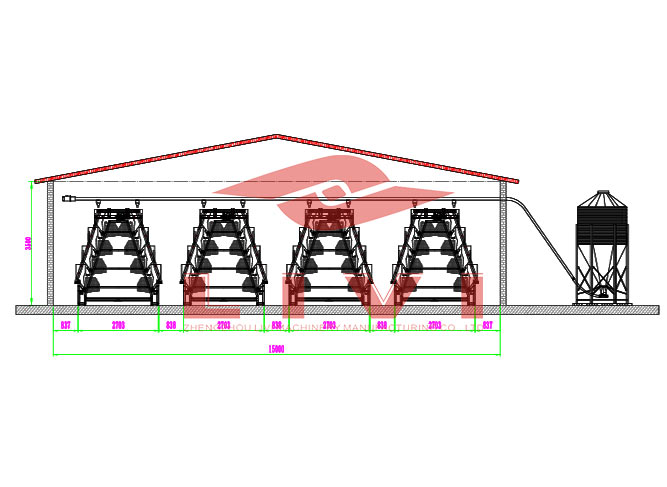

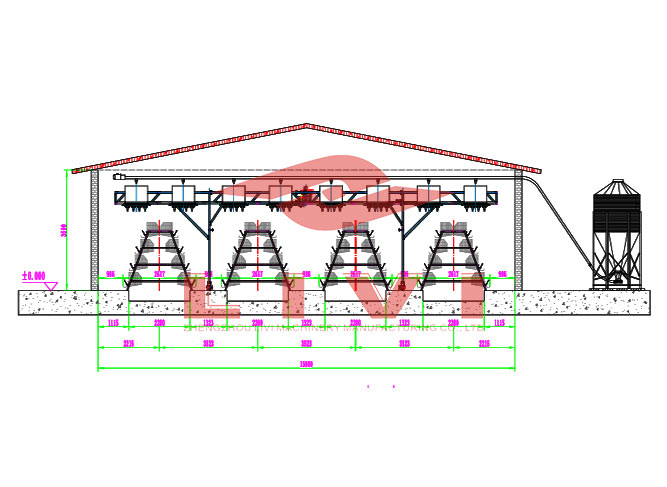

Farm Layout and Equipment Overview

The farm was designed with a 3-row × 43-unit configuration, ensuring even airflow and ease of access for maintenance. Each row accommodated over 6,600 birds, totaling 20,000 layers.

Key Equipment Supplied:

- 125 sets of A-type 4-tier cages

- 1 set of gantry-type automatic feeders

- 3 manure removal machines with polypropylene conveyor belts

- Environmental control system

Installation and Technical Support

Our engineering team offered remote technical guidance along with detailed civil construction drawings and assembly manuals. Livi Machinery’s local partner in Uganda assisted in on-ground coordination, helping complete installation within three weeks. Our team also trained the client’s farmworkers on how to operate and maintain the Automatic A-type Layer Cage System efficiently.

Customer Feedback

The Ugandan client reported significant improvements in egg production efficiency and hygiene. Labor costs dropped by over 40% due to automation, and the manure handling process became much cleaner and faster. The client also appreciated the structural stability and rust-proof quality of our cages, especially under the local humid conditions. Plans are already underway for a future 10,000-bird expansion.

Why Choose Livi’s Automatic A-type Layer Cage System?

Livi Machinery specializes in delivering high-performance poultry equipment tailored to your regional needs. Our Automatic A-type Layer Cage Systems are widely used across Africa due to their:

- Compact and stable design

- Full automation for feeding, manure removal, and egg collection

- Longevity with hot-dip galvanized materials

- Customization options for different climate zones

We provide one-stop service from design to delivery and after-sales technical support to ensure your poultry business grows sustainably.