Automatic H Type Layer Cages for 20,000-Chicken Poultry Project in Bolivia

Project Overview

In 2025, a poultry farm in Bolivia partnered with LIVI Machinery to upgrade its layer farming capacity by adopting Automatic H Type Layer Cages. The project aimed to house 20,000 laying hens in a single, well-ventilated closed chicken house while maintaining stable production, high efficiency, and minimal labor.

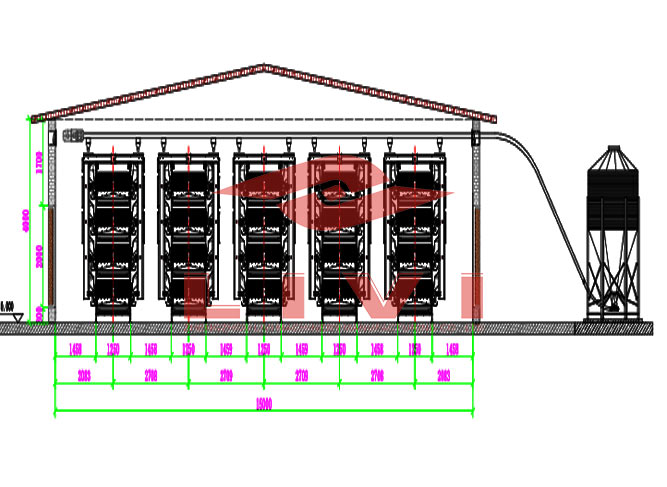

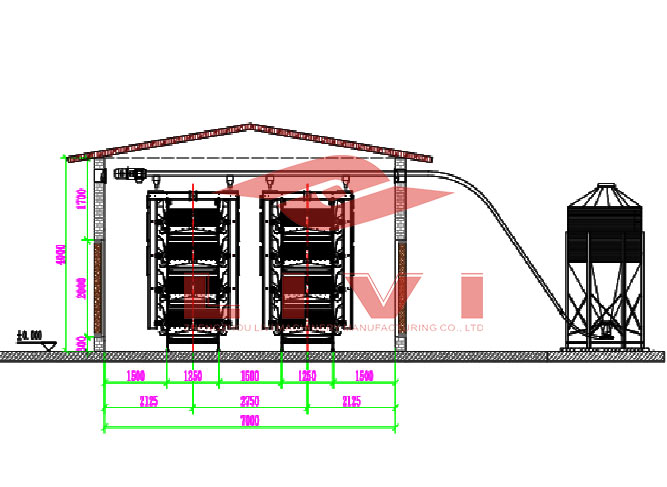

To meet these goals, LIVI customized a 3-row layout of 4-tier H-type layer cages, integrated with fully automated systems for feeding, manure removal, egg collection, and climate control. The cage system was built for durability, automation compatibility, and adaptability to Bolivia’s variable climate conditions.

Project Details

Location: Bolivia

Farming Scale: 20,000 laying hens

Cage Model: Automatic H Type Layer Cages – 4 Tiers

Chicken House Layout: Single house, 3 rows

Total Cage Sets: 141 sets (47 sets per row × 3 rows)

Birds per Cage Set: 144 birds

Total Capacity: 20,304 birds

House Size: Approx. 66 meters long × 10 meters wide

Client Requirements and LIVI’s Solution

Client Requirements:

- Efficient cage system to accommodate 20,000 layers in a single closed house

- Full automation to reduce labor input

- Reliable ventilation and temperature control

- Durable cage structure with long service life

LIVI’s Solution with Automatic H Type Layer Cages:

- Supplied 141 sets of 4-tier H-type cages with 3-row layout

- Configured a closed house with automated systems for feeding, egg collection, and manure cleaning

- Installed a ventilation system with cooling pads, exhaust fans, and air inlets

- Provided a nipple drinking system with pressure regulators to ensure consistent water supply

- Delivered full technical drawings, on-site planning, and remote support

Configuration of Automation and Climate Control System

| Automatic System | Configuration |

| Automatic Feeding System | 3 sets of feeding machines (1 per row) |

| Automatic Drinking System | Nipple drinking system with pressure regulators |

| Automatic Egg Collection System | 3 sets of automatic egg collection machines |

| Automatic Manure Cleaning | 3 sets of belt-type manure removal machines |

| Automatic Climate Control System | Cooling pads, exhaust fans, side windows, ventilation inlets |

The Automatic H Type Layer Cages were installed in a sealed house environment, ideal for consistent egg production and reduced disease risk. The client successfully minimized daily labor while improving the flock’s overall performance and output.

Client Feedback

The Bolivian client was highly satisfied with the automated cage system. With only a few workers, the farm achieved stable egg production, reduced operating costs, and improved environmental conditions. The structure proved reliable and efficient under local climate conditions, helping the farm transition into modern commercial layer farming.

Why Choose LIVI Automatic H Type Layer Cages

- Designed for commercial layer farms seeking full automation

- High-density layout optimized for 3-row or 5-row configurations

- Smooth integration of feeding, cleaning, and egg collection systems

- Hot-dip galvanized frame ensures long lifespan and corrosion resistance

- Excellent environmental adaptability for enclosed poultry houses

- Technical guidance and after-sales support included

Contact Us

ZHENGZHOU LIVI MACHINERY MANUFACTURING CO., LTD

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com

Upgrade your egg farm with LIVI’s Automatic H Type Layer Cages and experience the difference in efficiency and performance.