Automatic Type A 4-Tier Chicken Cages for 25,000 Layers in Tanzania

Project Overview

In April 2023, Livi Machinery successfully supplied and supported the installation of a fully automated layer cage system for a large-scale poultry farm located in Morogoro, Tanzania. The client, aiming to increase their production capacity and reduce labor dependency, selected Livi’s Automatic Type A 4-Tier Chicken Cages system to house 25,000 laying hens. The project was designed to meet the needs of industrial-scale egg farming with a focus on durability, hygiene, and automation.

Client Requirements and Our Tailored Solution

The Tanzanian client was upgrading from a semi-automated setup to a fully automated operation. Their key requirements included:

- Housing 25,000 layers in a compact, efficient layout

- Full automation for feeding, manure cleaning, and egg collection

- Strong, corrosion-resistant cage materials suitable for humid and warm environments

- Reduced labor costs and improved egg hygiene

Livi Machinery proposed a customized solution featuring:

- Automatic Type A 4-Tier Chicken Cages (hot-dip galvanized for long service life)

- Automatic gantry feeding machine for even feed distribution

- Belt-type manure removal system for clean and odor-free operation

- Egg collection conveyor system for rapid and gentle egg gathering

- Nipple drinking system with pressure regulators and medicator integration

This solution provided the perfect balance between performance and maintenance ease, ideal for large poultry farms in East Africa.

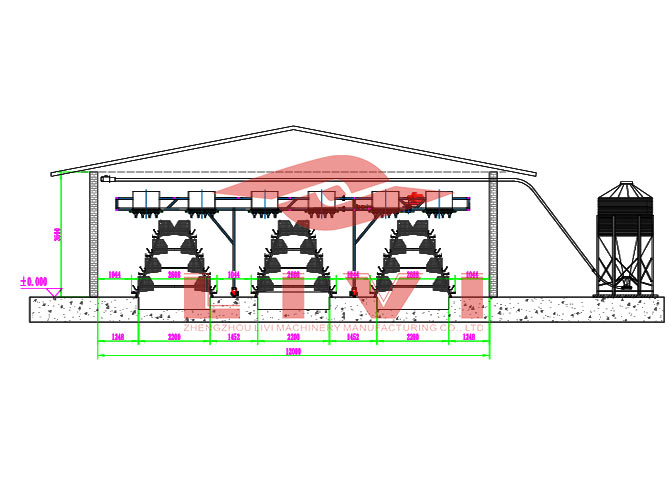

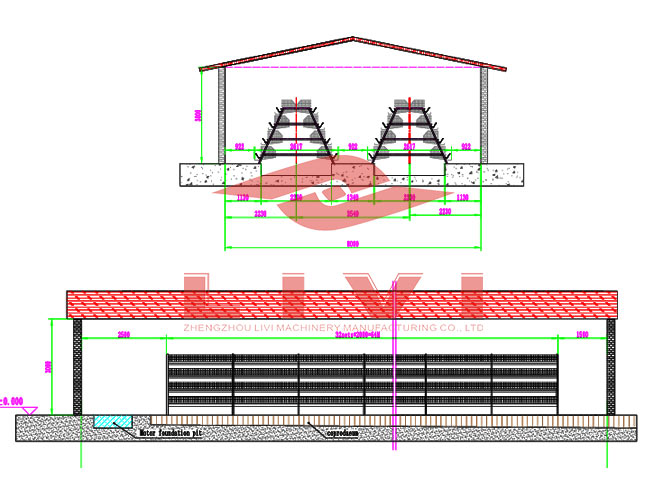

Farm Layout and Equipment Supplied

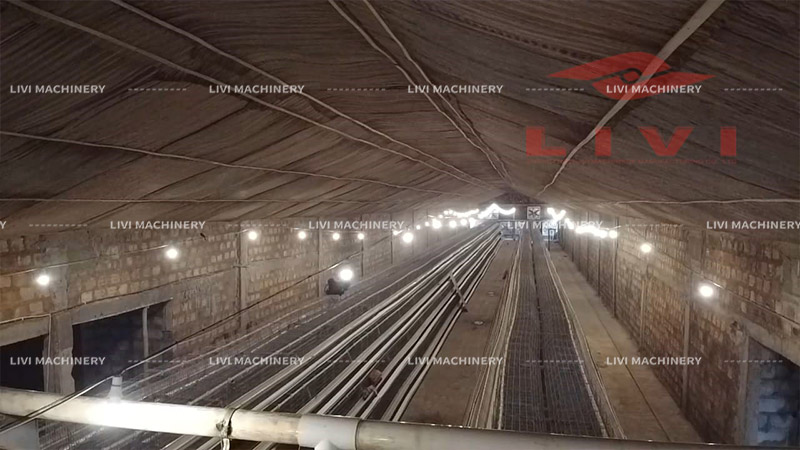

The poultry house was designed with 4 rows of A-type cages, each row holding over 6,000 birds, with a total system capacity of 25,000 layers. The design ensured optimal ventilation and efficient workflow.

Equipment Delivered:

- 158 sets of Automatic Type A 4-Tier Chicken Cages

- 4 automatic feeding machine

- 4 belt-driven manure removal systems

- 4 egg collection lines with egg conveyor belts

- Water tank system with filters and dosing medicator

- Installation tools, spare parts, and operation manuals

Installation and Technical Support

Livi provided 3D layout designs, concrete civil construction plans, and full remote installation support. The client also arranged for two Livi technicians to visit the site for hands-on guidance. With their assistance, the entire setup was completed in just over 4 weeks.

We trained the farm staff on:

- Automatic equipment operation

- Daily system inspection and maintenance

- Emergency procedures and troubleshooting

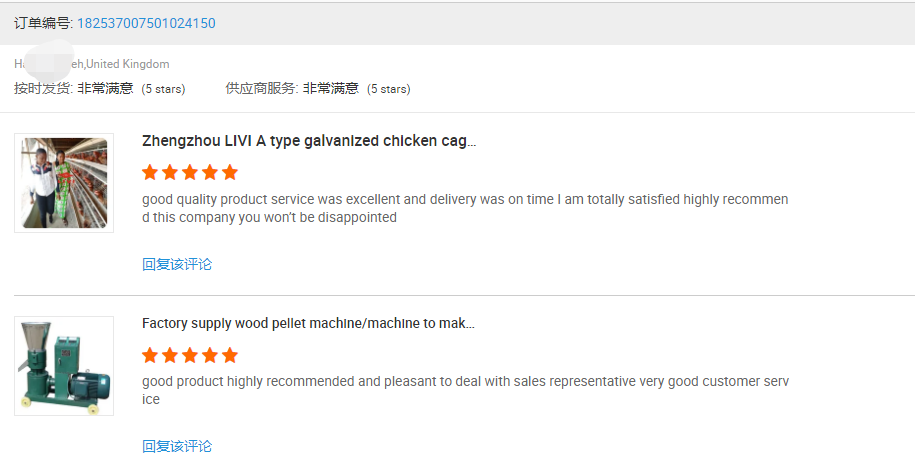

Customer Feedback

The Tanzanian client expressed great satisfaction with the Automatic Type A 4-Tier Chicken Cages, especially noting:

- Significant labor savings (over 50%)

- Smooth, uninterrupted egg collection with minimal breakage

- Cleaner and healthier bird environment

- High equipment durability in the local climate

The farm now averages over 22,000 eggs/day, with further expansion plans underway.

Why Choose Livi’s Automatic Type A 4-Tier Chicken Cages?

Livi Machinery delivers proven, high-capacity poultry solutions to over 70 countries. Our Automatic Type A 4-Tier Chicken Cages are ideal for large-scale farms looking to improve efficiency, reduce costs, and boost egg production. Features include:

- Robust galvanized steel construction

- Full automation for key farm processes

- Flexible layout and design assistance

- Professional technical support from concept to operation

No matter your farm’s size, Livi has the expertise to help you grow.