Battery Cage Poultry Farming with 40,000 Layers in Kenya

How H-Type 4-Tier Chicken Cages Enable Efficient Large-Scale Egg Production

Raising 40,000 laying hens in one poultry house may seem complex, but with the right equipment, it’s not only achievable — it’s efficient. In 2020, a professional poultry farmer in Kenya partnered with LIVI Machinery to build a fully automated battery cage poultry project using H-type 4-tier chicken cages, solving key challenges like land limitation, labor shortages, and climate adaptability.

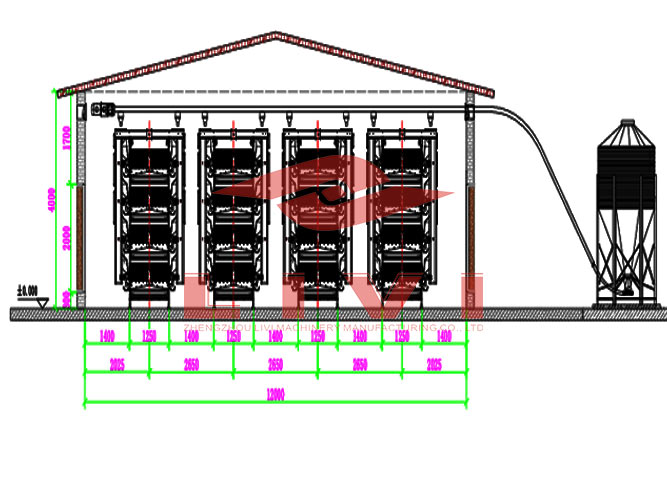

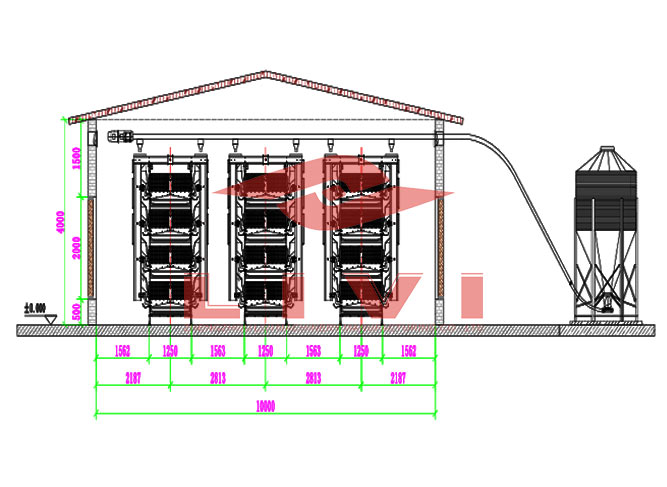

The system is housed in a single closed chicken house with 4 cage rows, designed to maximize bird density, simplify daily management, and ensure long-term durability under Kenya’s diverse weather conditions.

Project Summary

- Location: Kenya

- Total Bird Capacity: 40,000 laying hens

- Cage Model: H-type 4-tier chicken cages

- Cage Layout: Single house, 4 rows

- Number of Cage Sets Installed: 280 sets

- Birds per Cage Set: 144 birds

- Total Birds in Operation: 40,320 birds

- Automation Level: Full automatic feeding, egg collection, and manure removal

By installing 280 sets of H type battery cages, each holding 144 birds, the farm efficiently supports over 40,000 layers in a single building with minimal manual intervention.

Why the Client Chose H Type Battery Cages for the Kenya Project

Maximize Bird Capacity Within One Building

With 4-tier cage sets and 4 rows inside the house, the system makes full use of vertical and horizontal space. This high-density design reduces building and land costs while maintaining ventilation and accessibility.

Built for Kenyan Climate

The system is installed in a closed poultry house with environmental control, suitable for both dry and humid regions of Kenya. The cages are made of hot-dip galvanized steel, offering excellent corrosion resistance and a 15–20 year lifespan — ideal for farms in regions with variable temperatures and humidity.

Automation Reduces Labor Costs

To overcome rising labor expenses and improve daily efficiency, the farm includes:

- 4 sets of feeding machine

- 4 belt-type manure cleaning machines (one per row)

- 4 automatic egg collection systems

- Nipple drinking lines

The farm now runs smoothly with just a few trained staff members managing over 40,000 layers.

Equipment Supplied

| Equipment | Quantity | Description |

|---|---|---|

| H-type 4-Tier Chicken Cage Sets | 280 sets | 144 birds per set, 40,320 birds total |

| Automatic Feeding System | 1 set | For centralized feeding across all rows |

| Belt Manure Cleaning Systems | 4 sets | One per cage row |

| Egg Collection Machines | 4 sets | One per row, integrated egg belt system |

| Nipple Drinking System | Full set | Includes water pressure regulator |

| Climate Control System | Customized | Includes fans, cooling pads, air inlets |

Client Feedback

“We were looking for a system that could hold 40,000 birds in one house, reduce daily workload, and run reliably year-round. LIVI’s h type battery cages exceeded our expectations. From feeding to egg collection, everything is automated and well-structured. We’ve already seen improvements in productivity and egg quality.”

— Farm Owner, Kenya

The client highlighted the durability of the cage material, improved egg collection efficiency, and the cleaner environment as key benefits.

Benefits of H-Type 4-Tier Chicken Cages for Large-Scale Farms

- High density per square meter, ideal for commercial layer farms

- Compatible with full automation, reducing manual labor

- Clean environment thanks to effective waste removal

- Long-lasting galvanized structure for tropical climates

- Modular design, easy to expand or replicate for scaling

For poultry businesses aiming to expand production while maintaining efficiency and hygiene, LIVI’s h-type 4-tier chicken cages offer a smart and scalable solution.

Build Your High-Efficiency Poultry Project with LIVI Machinery

With more than a decade of experience and successful installations in over 70 countries, LIVI Machinery delivers customized poultry cage systems and complete farm solutions based on your climate, capacity, and operational goals.

📩 Email: [email protected]

📞 WhatsApp/WeChat: +86 155 3717 9350

🌐 Website: www.livimachinery.com