Battery Cages for Laying Hens: 20,000-Bird Poultry Project in Mozambique with H-Type 4-Tier Cage System

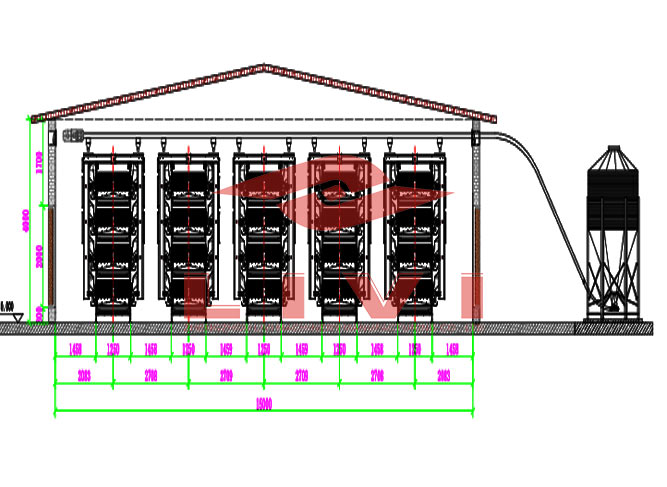

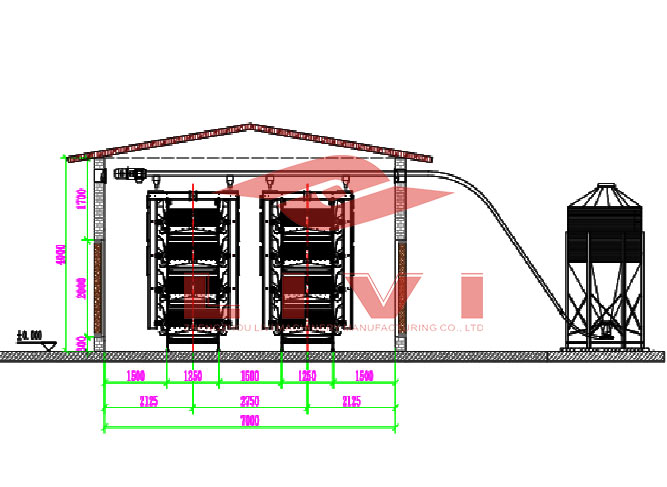

Mozambique’s poultry farm adopted LIVI’s battery cages for laying hens to house 20,000 layers in a single poultry house. The system features a high-density H-type 4-tier cage system arranged in four rows, with 140 sets of cages accommodating a total of 20,160 birds. Automation for feeding, egg collection, manure removal, and water supply is integrated to enhance efficiency and maintain hygiene throughout the farm.

The customer used A-type chicken cages for laying hens before, but he encountered the problem of chicken manure falling on the chickens and causing chicken diseases, so he wanted to upgrade to an H-type layer chicken cage system. He contacted us through a friend’s introduction, and we provided the customer with a detailed H-type automated battery cage poultry farming solution to meet his needs.

Project Overview

- Location: Mozambique

- Total Layers: 20,000 birds

- Cage Model: H-type 4-tier battery cages for laying hens

- Cage Layout: Single poultry house with 2 rows

- Number of Cage Sets: 140 sets

- Birds per Set: 144 birds

- Total Capacity: 20,160 birds

- Automation Included: Automatic feeding, manure cleaning, egg collection, and drinking system

Using 140 sets of H-type chicken battery cages, each housing 144 birds, the farm reaches a total installed capacity of 20,160 layers—perfectly aligning with the target of 20,000 hens while leaving room for management flexibility.

Equipment Supplied in Mozambique 20,000-Bird Poultry Project

| Equipment Lists | Quantity | Description |

| H-Type 4-Tier Layer Cage Sets | 140 sets | 144 birds per set, 20,160 layers total |

| Automatic Feeding Machine | 2 sets | Delivers feed evenly across both rows |

| Automatic Manure Cleaning System | 2 sets | One set for each cage row |

| Egg Collection Machines | 2 sets | Fully automatic, per row |

| Nipple Drinking System with Water pressure regulator | Full set | Ensures consistent water supply |

| Climate Control System | Customized | Includes fans, air inlets, curtains |

Why Use Battery Cages for Laying Hens in Mozambique?

Mozambique’s climate is warm and humid, which makes sanitation and disease control major concerns in poultry production. By using hot-dip galvanized H-type layer cages, the farm ensures rust resistance and long service life, even in tropical conditions.

The layer cage system features vertical stacking with 4 tiers, allowing high-density stocking while maintaining airflow. With just two rows in a single building, the layout is easy to manage, clean, and expand in the future.

Automation was essential to reduce daily labor. The gantry feeding machine, belt manure removal systems, and egg collection belts allow a small team to manage the entire farm efficiently. The battery cage system for layers not only saves time but also helps improve egg quality by reducing breakage and contamination.

Client Feedback

“We chose LIVI’s battery cages for laying hens because we wanted a long-lasting, easy-to-manage system that fits our budget and farm size. After installing the equipment, we immediately saw improvements in cleanliness, egg production, and worker efficiency. The automatic systems made everything easier to control, and the cage quality is excellent. We are happy with the results and planning to build another house next year.”

— Poultry Farm Owner, Mozambique

Advantages of H-Type Chicken Battery Cages for Egg Production

- Compact and space-saving layout

- Hot-dip galvanized materials for long-term use

- Full automation reduces labor needs

- Clean environment with better disease control

- Gentle egg handling with automatic collection belts

- Ideal for tropical climates and scalable operations

Build a Better Egg Farm with LIVI’s Battery Cage Systems

With more than 70 countries served and over 1,000 successful farm installations, LIVI Machinery provides professional poultry cage solutions tailored to your region, budget, and production goals. Our battery cages for laying hens are trusted by poultry farmers across Africa and beyond for their efficiency, reliability, and performance.

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com