Broiler Ground Raising System

Specification: Customized according to customer’s breeding scale or chicken house size (Length*Width).

Raw Material: PP Plastic

Lifespan: 15-20 Years

Product Introduction

The Ground Raising System for Broilers is a traditional yet highly effective solution for raising broiler chickens directly on the floor of the poultry house. Combined with modern automation equipment, this system is ideal for large-scale broiler farms aiming to achieve fast growth, low mortality, and optimized labor management.

It allows chickens to move freely within the house, providing better comfort and natural growth conditions, while maintaining efficient feeding, drinking, manure management, and environmental control.

🐥 Applicable For:

- Open or closed poultry houses

- Broiler chickens (1–45 days)

- Commercial meat production

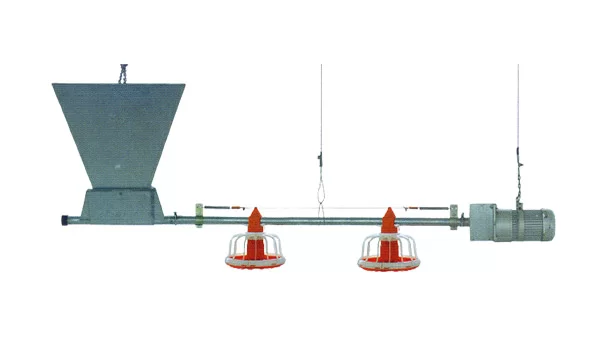

| Equipment Parts | Automatic Broiler Pan Feeding System |

| Feed Silo | Material: hot dip galvanized Sheet thickness: 1.00mm Capacity: recommended feed amount for 2-3 days. |

| Main Feeding Line | The capability of conveying food: 1400KG/h Material: High-carbon manganese steel Sensor imported from Germany |

| Pan Feeding Line | Hot galvanized pipe contains the auger, which can transfer the feed from the vice feed hopper to the end of the house. Broiler automatic feeder pan capacity: 30-35 broilers/per feed pan |

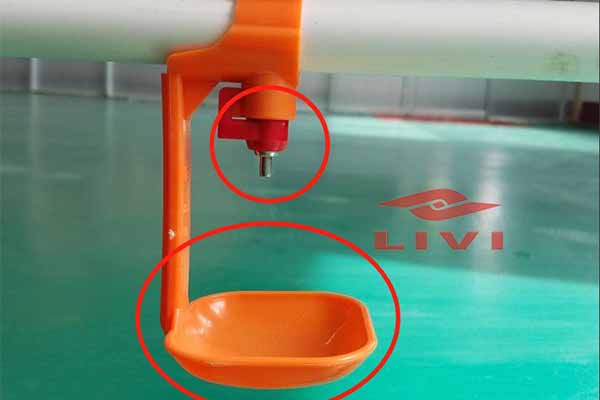

| Drinking Line | Water pipe with drinking nipples. Nipple capacity: 8-10 broilers/per nipple. |

Product Details and Ground Raising Equipment

A. Open Space Design

The design of the Broiler Ground Raising System emphasizes spaciousness, granting broilers the freedom of movement. This section provides an in-depth explanation of the layout and considerations for optimal density to ensure a stress-free environment for the broilers.

B. Feeding and Watering Systems

Efficient feeding and watering systems are critical for supporting broiler nutrition. This segment explores the features of automated systems that contribute to convenience and precision in maintaining the health of the broilers.

C. Shelter and Climate Control

The shelter design is crucial for protecting broilers against weather elements. This section discusses the elements of a well-designed shelter and the implementation of climate control measures to maintain optimal conditions for the broilers.

The water connection is sealed to prevent contamination.

The drinking nipple is highly sensitive and rotates 360 degrees.

Flexiable to adjust and a long lifespan

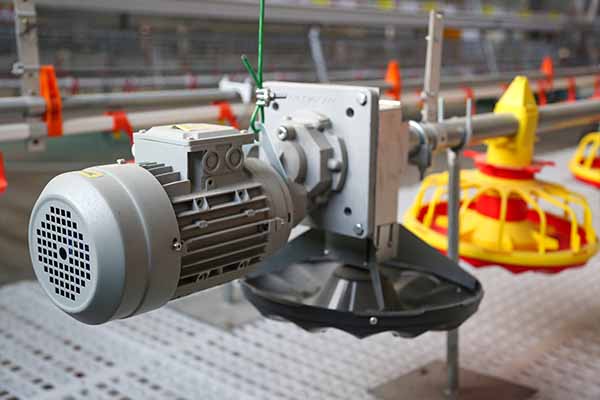

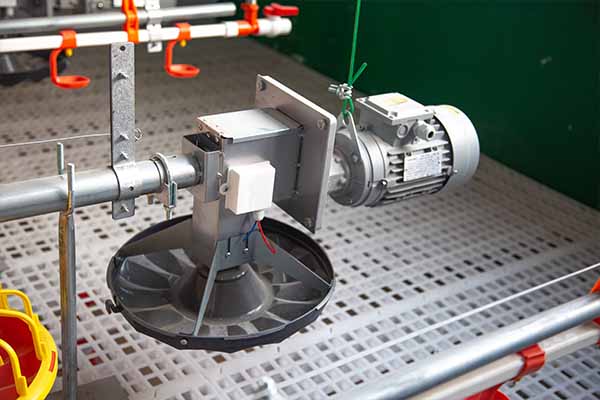

Voltage: 380V 50hz 3 phases

Rated power: 0.75-1.1KW

Taiwan brand

Capacity: 90-120KG

Material: Hot dip galvanized sheet Thickness: 1.00mm

Imported from German

Capacity: 30-35 broilers / per broiler feeder pan.

Deep Litter System Chicken Farm Design

A. Layout Considerations

A well-planned layout is essential for the efficiency of ground-raising operations. This part of the guide explores considerations for waste management and hygiene, ensuring a clean and organized environment.

B. Biosecurity Measures

To prevent disease outbreaks, biosecurity measures are imperative. This section delves into the incorporation of preventive measures in the ground-raising design to ensure the health and safety of the broilers.

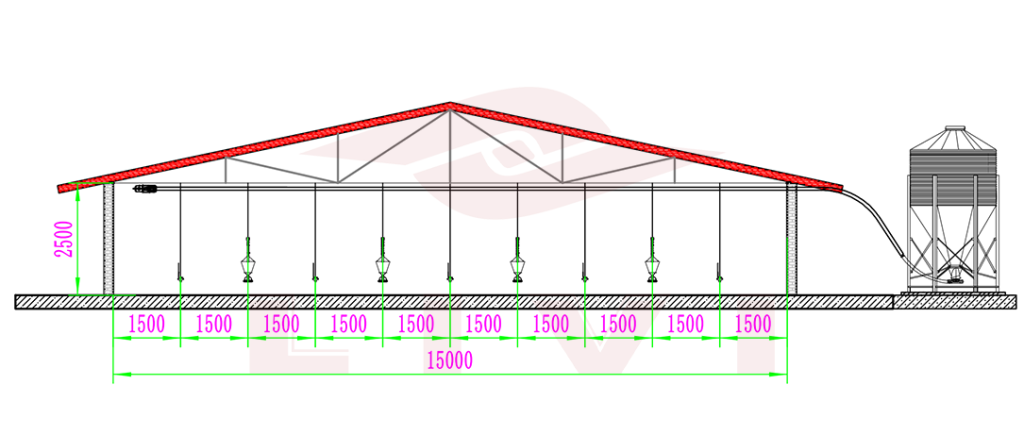

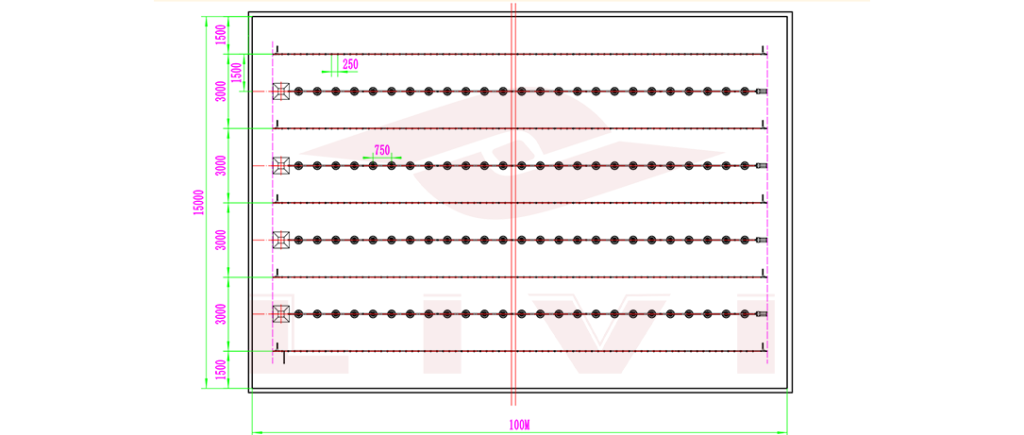

Layout Explanation: (Unit: mm)

1. Chicken Shed Size: 100000mm x 15000mm x 2500mm.

2. Configuration: 4 feed lines, 5 water lines.

3. Rearing Capacity: 15 birds/m².

The water line and the material line are staggered.

Generally, the water line and the material line are separated by 1.5M

The water trays are 25 cm apart

The trays are 75 cm apart

There is usually one more water line than the material line

Design the waterline layout according to the width of the chicken house.

Advantages of Broiler Ground Raising

A. Improved Broiler Welfare

Open space promotes natural behavior, leading to enhanced physical and mental well-being for the broilers. This segment discusses the positive impact of the ground-raising system on the overall welfare of the broilers.

B. Healthier Growth and Development

Reduced stress and improved air quality contribute to healthier growth and development in broilers. This part explores the influence of these factors on broiler weight gain and overall health.

C. Quality of Meat

Ground-raised broilers are known to yield better meat quality. This section provides insights into how natural exercise influences muscle development and, consequently, the quality of meat produced.

Project Cases

📍 Uzbekistan – 10,000 Birds Poultry Farm

📍 20,000 Broilers in Zimbabwe– Deep Litter System

📍 Tajikistan– 20,000 Broilers Poultry Farm

“We started using LIVI’s ground raising system for broilers in 2023. The equipment quality is excellent, and the automatic feeding and drinking lines have made daily management much easier. Our broilers grow uniformly and the mortality rate is very low. Even during the hot summer, the ventilation system kept the house environment stable. LIVI’s team gave us a complete farm design and remote installation support, which helped us a lot. We are very satisfied and plan to expand another house next year.”

— Mr. Niyazov, Poultry Farm Owner, Uzbekistan

Our Advantages

13+ Years of Manufacturing Excellence

Global Service in 70+ Countries

Flexible Farm Designs for Every Scale

Livi Machinery’s Service

From Farm Planning to After-Sales – One-Stop Poultry Farming Solution

- High quality Chicken Cage – 15-20 Years Lifespan

- Manufacturing & Delivery – 45-60 days

- On-Site Installation & Technical Training – 24-hour service

- Lifetime After-Sales Support – 3 Years Warranty