H Frame Layer Battery Cage System for 30,000 Chickens Commercial Layer Farm in Zambia

Project Overview

In early 2019, a commercial poultry farm in Zambia partnered with LIVI Machinery to build a high-efficiency layer production facility for 30,000 laying hens. The farm adopted the H Frame Layer Battery Cage System to ensure large-scale production with minimal labor and maximum operational stability. The solution was tailored to suit the regional climate, modern management requirements, and the customer’s long-term expansion plan.

LIVI provided a comprehensive design, equipment supply, and installation support service, enabling the Zambian client to complete a closed chicken house equipped with fully automated systems.

Project Details

Location: Zambia

Farming Scale: 30,000 laying hens

Cage Model: Layer Battery Cage System –H Frame, 4 Tiers

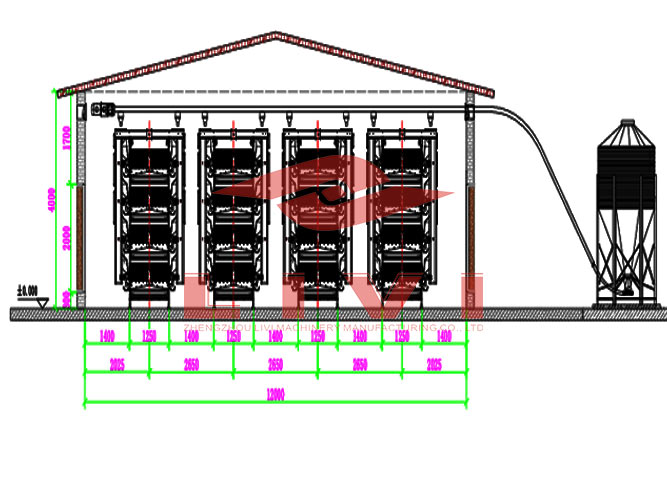

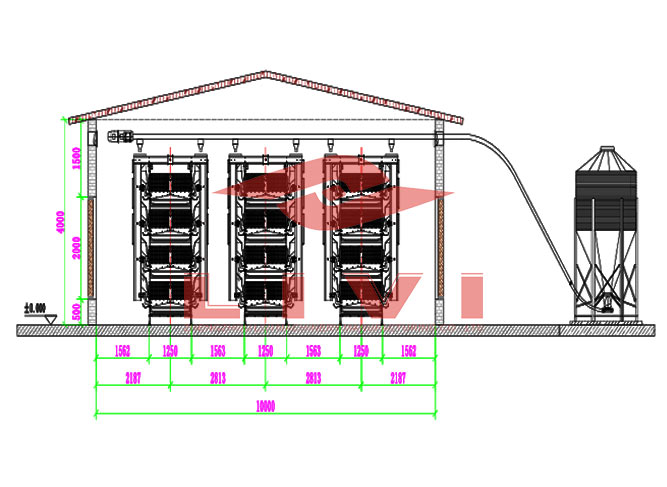

Chicken House Size: Approx. 93 meters long × 10 meters wide

Total Cage Sets: 210 sets arranged in 3 rows

Birds per Cage Set: 144 birds

Total Capacity: 30,240 birds

Client Requirements and LIVI’s Solution

Client Requirements:

- High-density cage layout to fit 30,000 hens in one house

- Full automation to reduce labor costs

- Environmental control to ensure productivity in Zambia’s hot and dry season

- Strong and durable cage structure for long-term use

LIVI’s Solution with H Frame Layer Battery Cage System:

- Designed a 93m × 10m closed chicken house, configured for 3 cage rows

- Supplied 210 sets of 4-tier H Frame Layer Battery Cages

- Implemented a complete automatic system for feeding, manure removal, egg collection, drinking, and ventilation

- Integrated a modern environmental control system suitable for closed housing in hot climates

- Provided technical guidance and support throughout installation and operation

Configuration of Automation and Climate Control System

| System | Configuration |

| Automatic Feeding System | 3 sets of feeding machines (1 per row) |

| Automatic Drinking System | Nipple drinking system with pressure regulators |

| Automatic Egg Collection System | 3 sets of automatic egg collection machines |

| Automatic Manure Cleaning | 3 sets of belt-type manure removal machines |

| Automatic Climate Control System | Cooling pads, exhaust fans, side windows, ventilation inlets |

The H Frame Layer Battery Cage System was applied inside a fully enclosed chicken house to ensure reliable egg production, better disease prevention, and stable performance in Zambia’s climate.

Client Feedback

The Zambian farm owner praised the system for its efficiency and ease of operation. The automation system allowed only a few workers to manage 30,000 birds while keeping production levels high. The climate control system was especially effective during the dry season. The H Type Layer Battery Cage System offered both reliability and long-term economic benefit.

Why Choose LIVI H Frame Layer Battery Cages for Your Poultry Farm?

- Designed for intensive commercial egg farms

- Optimized for space usage, ventilation, and hygiene

- Fully automated operation for feeding, manure removal, egg collection, and ventilation

- Corrosion-resistant structure with long service life

- Suitable for closed houses in hot climate regions

- Exported to over 70 countries with installation support

Contact Us

Start building your high-efficiency poultry business today with our professional H Frame Layer Battery Cage System.