H-type 4-Tier Battery Cages for 40,000 Layers Poultry Farm Project in Malawi

Project Overview

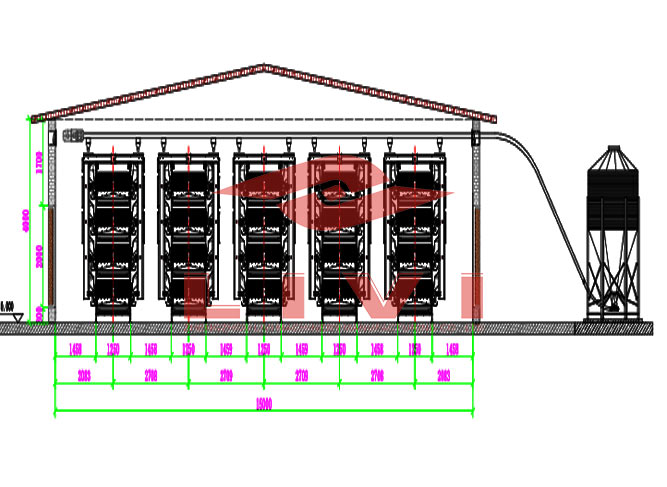

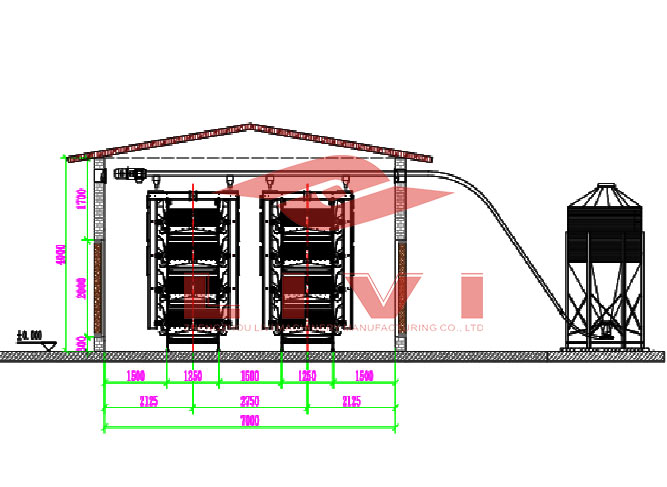

Malawi’s growing poultry industry demands efficient and hygienic housing solutions. This project installed LIVI’s H-type 4-tier battery cages in a single poultry house to accommodate 40,000 laying hens. The system uses four rows of cages with 139 sets each, providing a total capacity of 40,032 birds. Automated equipment manages feeding, egg collection, manure removal, and drinking water supply, improving farm productivity and hygiene.

The farm chose this system to prevent egg contamination during Malawi’s rainy season by utilizing the enclosed cage design and automatic egg collection, which maintains cleaner eggs and healthier birds.

- Location: Malawi

- Total Layers: 40,000 birds

- Cage Model: H-type 4-tier battery cages

- Cage Layout: Single poultry house with 4 rows

- Number of Cage Sets: 278 sets

- Birds per Set: 144 birds

- Total Capacity: 40,032 birds

- Automation Included: Automatic feeding machine, automatic manure cleaning systems, automatic egg collection machines, automatic nipple drinking system and automatic environmental control system.

Equipment Supplied in This 40,000 Layers Poultry Farm Project

| Equipment Lists | Quantity | Description |

| H-Type 4-Tier Layer Cage Sets | 278 sets | 144 birds per set, total capacity 40,032 birds |

| Automatic Feeding Machine | 4 sets | Even feed delivery across all 4 rows |

| Automatic Manure Cleaning System | 4 sets | One set per cage row for efficient manure removal |

| Egg Collection Machines | 4 sets | Fully automatic egg collection per row |

| Nipple Drinking System with Water pressure regulator | Full set | Provides stable water supply for all layers |

| Climate Control System | Customized | Includes fans, air inlets, and curtains etc. for ventilation |

Why Choose H-type Battery Cages in Malawi?

Malawi’s hot and humid climate requires durable and corrosion-resistant equipment. LIVI’s hot-dip galvanized H-type battery cages ensure long service life and rust protection under tropical conditions. The 4-tier vertical design optimizes space while maintaining proper airflow and easy management.

Automation helps reduce labor costs significantly. The gantry feeding machine, belt manure cleaning systems, and automatic egg collection belts improve cleanliness and egg quality. This battery cage system supports efficient, large-scale layer farming with better biosecurity and productivity.

Client Feedback

“We chose LIVI’s H-type 4-tier battery cages to increase capacity while minimizing labor. The equipment quality and automation greatly improved our farm’s efficiency and egg production. The system is easy to manage and maintain. We plan to expand soon.”

— Poultry Farm Owner, Malawi

Advantages of H-type 4-tier Battery Cages for Layers

- Space-saving vertical design with 4 tiers

- Hot-dip galvanized materials for tropical durability

- Fully automated feeding, manure cleaning, and egg collection

- Cleaner environment reduces disease risks

- Ideal for large-scale commercial layer production

Build a Modern Egg Farm with LIVI Machinery

LIVI Machinery has supplied professional poultry cage solutions to over 70 countries with more than 1,000 successful projects. Our H-type 4-tier battery cages combine durability, automation, and efficiency to help you build a modern and productive egg farm.

Contact Information:

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com