H Type Battery Cage System for 50,000 Broiler Automated Poultry Farm in Kazakhstan

Introduction

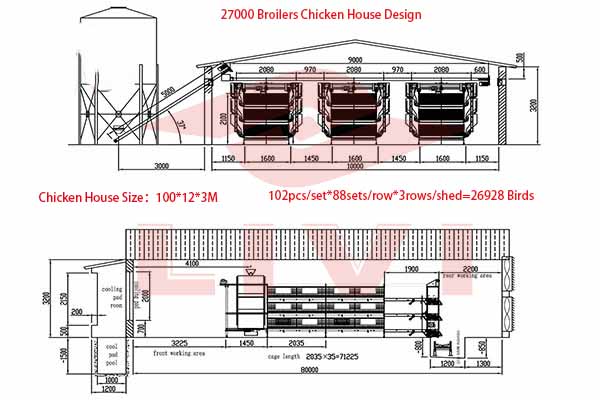

The H Type Battery Cage System is a highly efficient and automated solution for large-scale broiler farming. This case study explores its successful implementation in a 50,000-broiler automated poultry farm in Kazakhstan, highlighting the advantages of H-type broiler cages in meat production.

Project Overview

- Location: Kazakhstan

- Farm Capacity: 50,000 broilers

- Cage System: H-type battery cage system ( 4-tier configurations)

- Automation Level: Full automation (feeding, watering, ventilation, and manure removal)

- Key Benefits: High-density farming, labor savings, improved biosecurity, and enhanced growth performance

Client Requirements and Solutions Provided

Client Requirements:

- Housing for 50,000 broiler chickens in a controlled environment.

- Efficient feeding and watering systems to reduce feed waste.

- Automated manure cleaning to maintain hygiene and improve air quality.

- Reliable ventilation and temperature control suitable for Kazakhstan’s climate.

- Durable and easy-to-maintain cage system to withstand long-term usage.

- Integration of monitoring systems to track feed intake, water consumption, and environmental parameters.

Our Solutions:

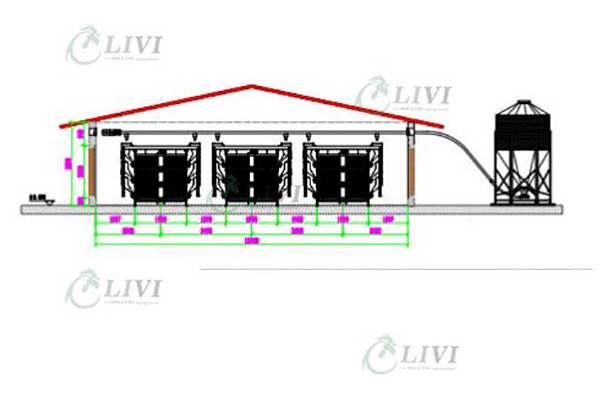

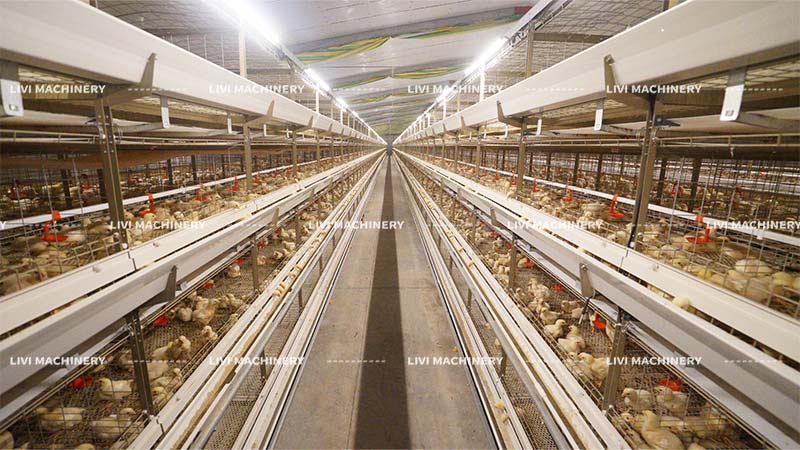

- H Type Battery Cage System:

The H Type design features robust, multi-tiered cages tailored for broiler chickens, optimizing space use and ensuring birds’ comfort. The modular system allows easy expansion and maintenance. - Automated Feeding System:

Gantry feeding machines deliver feed evenly and on schedule, minimizing waste. The system is designed for 1 gantry machine per poultry house, ensuring efficient feed distribution. - Nipple Drinking System with Water Tanks:

Provides clean water supply to all birds, reducing contamination risks and water wastage. - Automated Manure Cleaning System:

Belt manure cleaning machines are installed per cage column, enabling fast, continuous removal of manure to keep the environment clean and reduce ammonia buildup. - Ventilation and Climate Control:

Custom ventilation design includes fans, air inlets, and temperature sensors to maintain optimal air quality and temperature throughout the year, adapted to Kazakhstan’s harsh winters and hot summers. - Egg Collection (if layer birds used in future):

Although this farm is for broilers, the system is designed to be upgradeable with egg collecting machines if layer production is considered later.

Why Choose H-Type Battery Cage System for Broilers?

1. High-Density Farming with Optimal Space Utilization

The H-type broiler cages allow vertical stacking, maximizing floor space while ensuring proper ventilation and easy management.

2. Automated Feeding & Watering Systems

- Feeding: Equipped with chain or pan feeding systems for uniform feed distribution.

- Watering: Nipple drinkers with pressure regulators ensure clean water supply, reducing spillage and disease risk.

3. Efficient Manure Management

- Belt-type manure removal system keeps the environment dry and hygienic.

- Reduced ammonia levels, improving air quality and broiler health.

4. Enhanced Growth Performance

- Controlled environment (temperature, humidity, and ventilation) ensures optimal growth.

- Lower mortality rates due to reduced stress and disease exposure.

Technical Specifications

| Parameter | Specification |

|---|---|

| Cage Type | H-Type Battery Cages for Broilers |

| Tiers | 4-tier |

| Capacity per Cage | 136 broilers |

| Material | Hot-dip galvanized steel |

| Automation | Feeding, watering, ventilation, manure removal |

| Lifespan | 15-20 years |

Conclusion

The H Type Battery Cage System is an ideal solution for large-scale broiler farming, offering automation, efficiency, and improved meat production. This 50,000-broiler farm in Kazakhstan demonstrates how H-type broiler cages enhance productivity while reducing operational costs.