H Type Battery Chicken Cage System for 30,000 Layers Automated Poultry Farm in Nigeria

Project Overview

In 2021, a poultry farm in Nigeria launched a modern layer breeding facility for 30,000 hens using the H Type Battery Chicken Cage System for Layers. This project was designed and supported by LIVI Machinery, with the goal of achieving high-density, low-labor, and fully automated egg production.

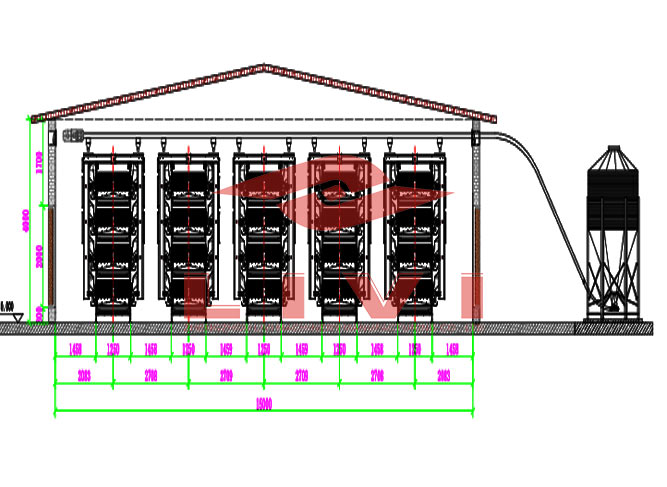

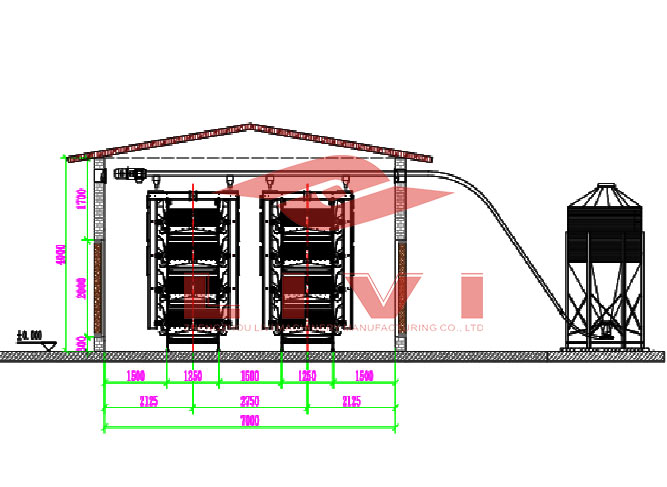

The customer required a single chicken house solution with optimal ventilation and climate adaptability. LIVI delivered a 3-row layout of 4-tier H type cages, integrated with a complete automation system and a closed-house environmental control system, perfectly suited for Nigeria’s tropical climate.

Project Details

Location: Nigeria

Farming Scale: 30,000 laying hens

Cage Model: H Type Chicken Cage for Layers – 4 Tiers

Chicken House Layout: Single house, 3 rows

Total Cage Sets: 210 sets (70 sets per row × 3 rows)

Birds per Cage Set: 144 birds

Total Capacity: 30,240 birds

Chicken House Size: Approx. 93 meters long × 10 meters wide

Client Requirements and LIVI’s Solution

Client Requirements:

- Efficient cage system to house 30,000 layers in a single chicken house

- Automated feeding, manure removal, and egg collection

- Closed-house design to manage heat and disease control

- Durable, easy-to-maintain structure

LIVI’s Solution with H Type Battery Chicken Cage System for Layers:

- Provided 210 sets of 4-tier H Type Battery Chicken Cages arranged in 3 rows

- Designed the house to be 93 meters long and 10 meters wide

- Configured full automation for feeding, egg collection, manure cleaning, and drinking

- Installed an automatic climate control system tailored for a closed poultry house

- Supplied installation layout, drawings, and after-sales technical support

Configuration of Automation and Climate Control System

| Automatic System | Configuration |

| Automatic Feeding System | 3 sets of feeding machines (1 per row) |

| Automatic Drinking System | Nipple drinking system with pressure regulators |

| Automatic Egg Collection System | 3 sets of automatic egg collection machines |

| Automatic Manure Cleaning | 3 sets of belt-type manure removal machines |

| Automatic Climate Control System | Cooling pads, exhaust fans, side windows, ventilation inlets |

This poultry house was built as a fully enclosed system, enhancing ventilation, temperature regulation, and biosecurity. The Automatic H Type Chicken Cage System for Layers significantly improved egg production efficiency and reduced operational workload.

Client Feedback

The Nigerian client was very satisfied with the results. The cage layout and automation helped reduce labor costs and ensured the chickens remained in good condition despite high ambient temperatures. With only a small team, the farm achieved stable daily egg output and excellent operational efficiency.

Why Choose LIVI H Type Battery Chicken Cage System for Layers

- Supports high bird density with efficient space utilization

- Fully automated operation reduces labor and improves consistency

- Climate-adaptive design for enclosed poultry houses

- Durable hot-dip galvanized steel structure

- Easy to install, operate, and maintain

- Proven success in over 70 countries with local installation service

Contact Us

ZHENGZHOU LIVI MACHINERY MANUFACTURING CO., LTD

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com

Build a successful automated poultry farm with LIVI’s professional H Type Battery Chicken Cage System for Layers.