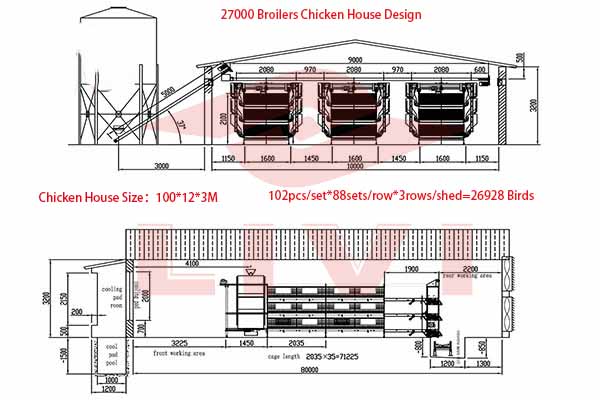

H Type Broiler Cages for 20,000-Chicken Poultry Farm in Ghana

Project Overview

This poultry project is located in Ghana, where the client aimed to establish a modern broiler farm for 20,000 chickens. As a growing poultry business, the customer was seeking to increase production scale while reducing labor intensity and improving hygiene standards. After evaluating multiple equipment suppliers, the client partnered with LIVI Machinery, known for their reliable cage systems and turnkey poultry solutions.

To meet the farm’s needs, H Type Broiler Cages were selected for their high density, space-saving structure, and compatibility with automatic systems.

Customer Requirements & Our Solution

Customer Requirements

- Raise 20,000 broiler chickens across two poultry houses

- Improve biosecurity and cleanliness with cage farming

- Use automated systems for feeding, drinking, and manure removal

- Ensure equipment is durable, easy to maintain, and well ventilated

- No special requirement for automatic bird harvesting

LIVI’s Solution

- Supplied H Type 4-tier broiler cages, each set raising 136 birds

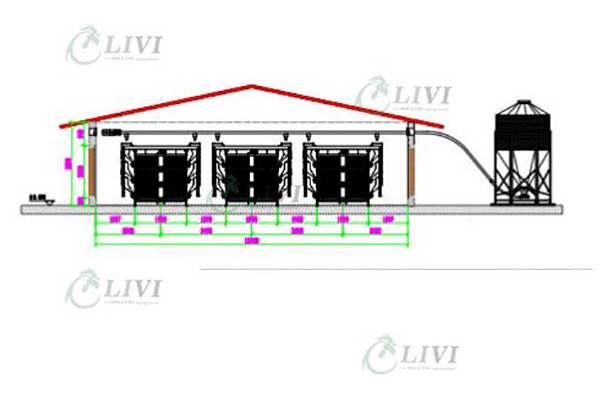

- Designed two poultry houses with proper aisle spacing and ventilation layout

- Installed full sets of automatic drinking system with water tanks and nipple drinkers

- Equipped each tier with belt-type manure cleaning system

- Provided traveling-type feeding machines for even and efficient feed delivery

- Included a smart environmental control system to manage temperature, humidity, and airflow

Equipment Configuration Summary

| Equipment | Description |

| Cage Model | H Type, 4-tier, 1-door, 136 birds per set |

| Total Cage Sets | 148 sets × 1 house = 148 sets |

| Total raising quantity | 148 sets × 136 birds per set= 20,128 birds |

| Drinking System | Nipple drinkers + water tanks, 1 per tier |

| Feeding System | Traveling feeding machine (1 per row) |

| Manure Removal | Belt-type manure cleaning system (1 per tier) |

| Environment Control | Ventilation fans, cooling pads, side inlets, intelligent panel |

Why H Type Broiler Cages?

- Higher stocking density – saves space and increases output per square meter

- Full automation – reduces labor and improves efficiency

- Improved cleanliness – broilers are raised above manure, reducing disease risks

- Durable and long service life – cages are made with high-zinc hot-dip galvanized steel

- Ideal for commercial farms – especially in hot climates like Ghana

Client Feedback

The customer was pleased with the system performance and LIVI’s support:

“This is a major step forward for our farm. The H Type broiler cages work perfectly and save us a lot of time every day. We’re seeing better growth rates and a cleaner environment. LIVI’s solution really helped us modernize our poultry operation.”

What LIVI Can Do for You

LIVI Machinery provides full-scale broiler and layer farming solutions with decades of experience. We support clients in over 70 countries with:

- Tailored poultry house designs

- High-quality cage and automation systems

- Remote and on-site technical support

- Local installation services in Africa

📧 Email: [email protected]

📞 WhatsApp/WeChat: +86 155 3717 9350

🌐 Website: www.livimachinery.com