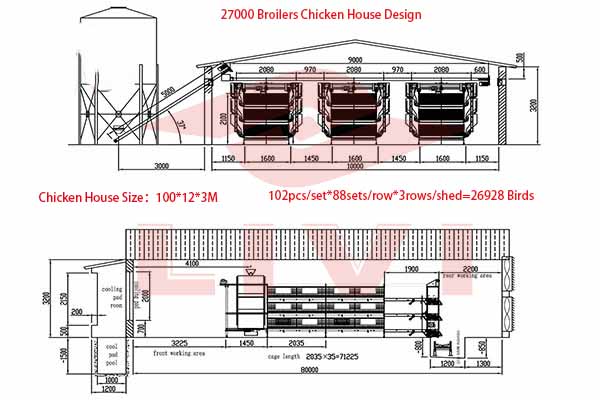

H-Type Chicken Cages for 20,000 Broilers Poultry Farm in Kyrgyzstan

Project Overview

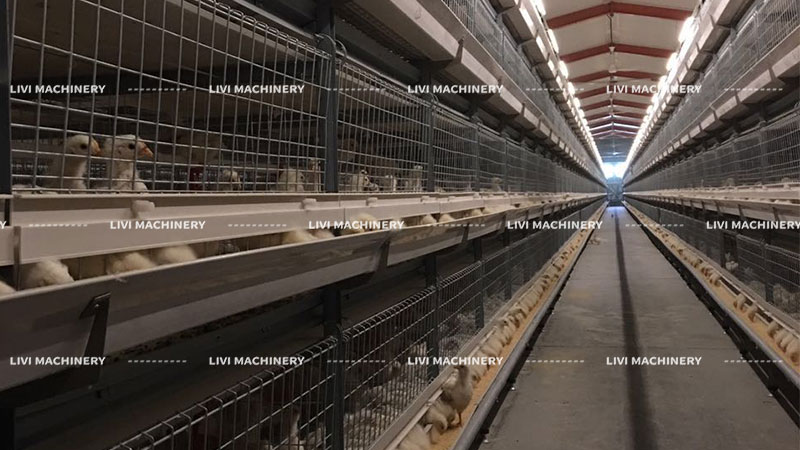

In Kyrgyzstan, a poultry farm with a capacity of 20,000 broilers adopted our efficient H-Type Chicken Cages, marking a shift toward vertical and automated broiler farming.

Client Requirements & Solution

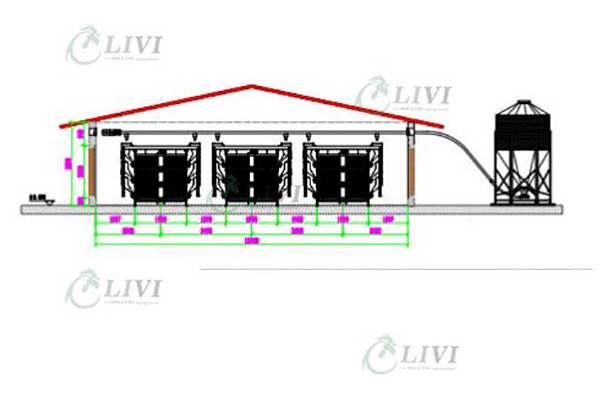

The client wanted a durable and scalable solution that could support future expansion. Our team proposed the H-type battery cage system with a 4-tier 1-door layout to make full use of the available shed space. All systems were designed to reduce labor and enhance broiler performance.

Equipment Supplied

- H-Type Chicken Cages (4-tier, 1-door), 147 sets

- Bird capacity per set: 136 birds

- Total birds raised: 20,000

- Automatic gantry feeding system

- Manure removal system: Belt system, 1 set per row

- Drinking system: Nipple drinkers with water regulators

Customer Feedback

The client reported excellent bird performance and appreciated the technical support provided during installation. The cages offered efficient manure management and improved air quality in the shed. Plans are underway for a second shed using the same system.

Why Choose Automatic H-Type Chicken Cages for Broiler Chickens?

- Sturdy Structure: Heavy-duty steel ensures long-term use.

- Automated Systems: Reduces labor and improves feeding precision.

- High Broiler Output: Consistent bird size and fast turnover.

- Modular Flexibility: Easily adapted for various house sizes and layouts.

What Can LIVI Do for Your Farm?

LIVI has more than 12 years of experience serving poultry farms in over 70 countries. We provide end-to-end support, from farm design to cage installation, with local installation teams and remote guidance available anytime.

Contact Us

📧 Email: [email protected]

📱 WhatsApp/WeChat: +86 155 3717 9350

🌐 Website: www.livimachinery.com