H Type Chicken Cages for 50,000 Layers Poultry Project in Uzbekistan

Project Overview

In 2020, a large-scale commercial poultry farm in Uzbekistan partnered with LIVI Machinery to establish a new automated egg production facility. To accommodate 50,000 laying hens within a single chicken house, the farm adopted LIVI’s H Type Chicken Cages, known for their compact structure, high durability, and compatibility with automated systems.

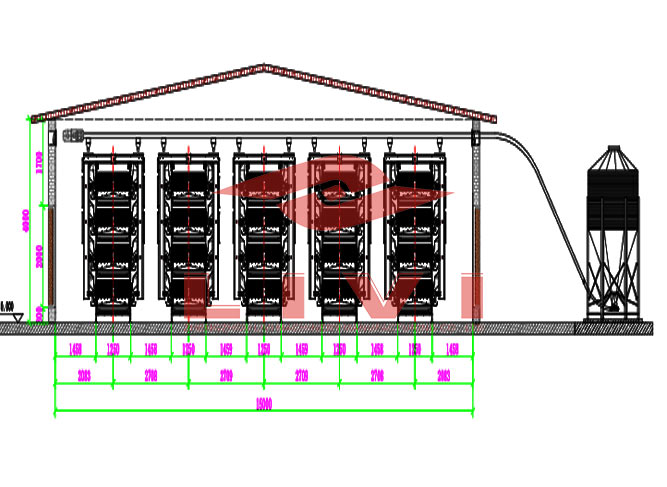

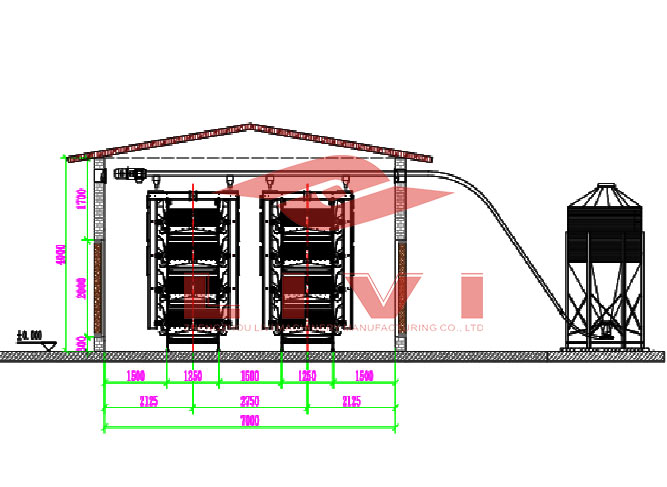

The Uzbekistan client required a high-capacity solution that could ensure continuous production under the country’s continental climate. LIVI delivered a full-scale project plan with five rows of 4-tier H type cages, automation systems, and a climate-controlled closed house, enabling efficient and stable operations.

Project Details

Location: Uzbekistan

Farming Scale: 50,000 laying hens

Cage Model: H Type Chicken Cages – 4 Tiers

Chicken House Layout: Single house, 5 rows

Total Cage Sets: 350 sets (70 sets per row)

Birds per Cage Set: 144 birds

Total Capacity: 50,400 birds

House Size: Approx. 93 meters long × 12 meters wide

Client Requirements and LIVI’s Solution

Client Requirements:

- Cage system to house 50,000 layers in one modern poultry building

- Reliable performance in extreme seasonal temperature differences

- Automated systems to reduce manpower

- Enclosed housing with strong environmental control

LIVI’s Solution with H Type Layer Chicken Cages:

- Designed a 5-row layout using 350 sets of H Type Chicken Cages, 4 tiers each

- Configured the house with full automation including feeding, manure removal, egg collection, and drinking systems

- Integrated an automatic ventilation and cooling system suitable for both hot summers and cold winters

- Provided technical drawings, equipment layout planning, and after-sales installation support

- Ensured efficient cage layout with high bird density and easy daily management

Configuration of Automation and Climate Control System

| Automatic System | Configuration |

| Automatic Feeding System | 5 sets of feeding machines (1 per row) |

| Automatic Drinking System | Nipple drinking system with pressure regulators |

| Automatic Egg Collection System | 5 sets of automatic egg collection machines |

| Automatic Manure Cleaning | 5 sets of belt-type manure removal machines |

| Automatic Climate Control System | Cooling pads, exhaust fans, side windows, ventilation inlets |

The H Type Chicken Cages were installed in a fully enclosed poultry house, creating a controlled environment that improved egg quality, reduced mortality, and enhanced disease prevention.

Client Feedback

The client in Uzbekistan appreciated LIVI’s professional support and fast delivery. With the automation system in place, they were able to manage 50,000 laying hens using minimal labor while maintaining steady egg production. The cage system performed well in both hot and cold seasons, proving its adaptability and value.

Why Choose LIVI H Type Chicken Cages

- Maximize space efficiency with multi-tier cage design

- Compatible with full automation for large-scale farms

- Strong and durable cage structure for long-term use

- Supports stable production in closed houses under various climate conditions

- Backed by complete design, layout, and installation service

- Trusted by over 1,000 layer farms worldwide

Contact Us

ZHENGZHOU LIVI MACHINERY MANUFACTURING CO., LTD

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com

Boost your farm’s performance with LIVI’s H Type Chicken Cages, designed for large-scale, automated egg production.