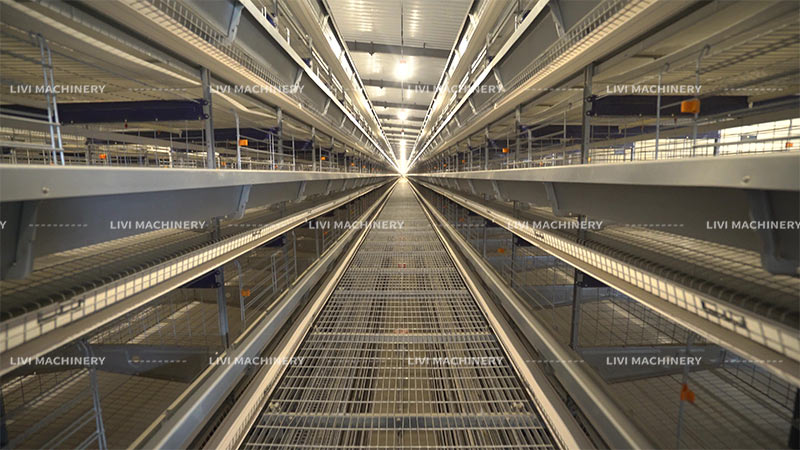

H Type Layer Chicken Cage System

Breeds: laying hens

Rearing Quantity / House: 20,000-100,000 birds

Lifespan: 15-20 Years

Tiers: 3-8 Tiers

Material: International Q235 steel

Anti-corrosion Treatment Process: Hot-dip Galvanized

Certificate: ISO9001, CE, SONCAP, PVOC

Product Introduction

The H Type Layer Chicken Cage System is a fully automatic chicken cage system designed for large-scale egg production farms. With a vertical, stacked structure and complete automation, this system is ideal for modern poultry operations seeking labor efficiency, space utilization, and high biosecurity.

Application: Layer chickens (commercial egg production)

Capacity Range: 20,000–100,000 birds per farm

Material: Hot-dip galvanized steel, corrosion-resistant for up to 15+ years

Suitable for: Closed chicken houses with automatic climate control

Specifications of H type layer chicken cage system

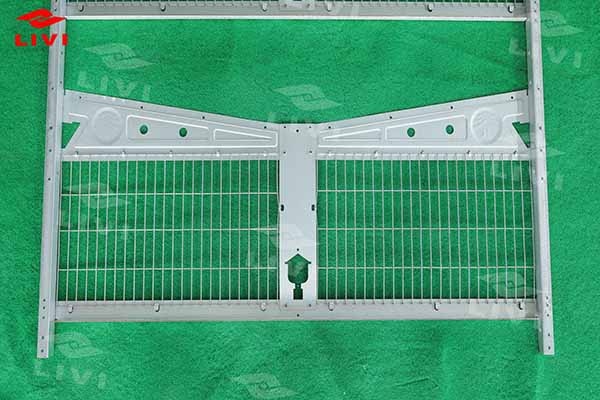

Solid construction

Hierarchical design

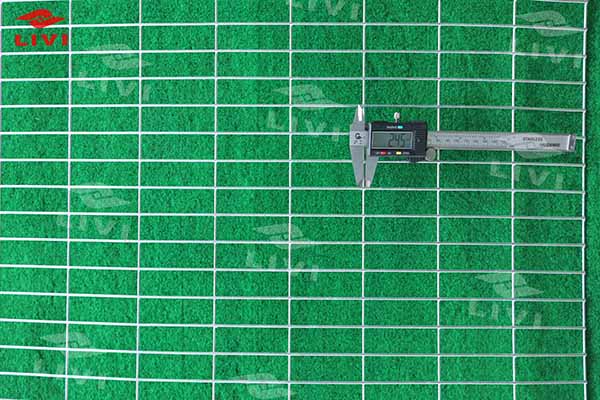

High quality metal material

Grid design

chicken drinking line

Dimensions: Tailored to accommodate varying flock sizes, offering flexibility for large-scale operations.

| H-type Layer Chicken Battery Cage Specification | ||||

| Type | Door/Tier | Birds Qty/Door | Birds Qty/Set | Specification |

| H-type | 3-tier 2-door | 9 | 108 | 1200mm*625mm*480mm |

| 4-tier 2-door | 9 | 144 | 1200mm*625mm*480mm | |

| 5-tier 2-door | 9 | 180 | 1200mm*625mm*480mm | |

| 6-tier 2-door | 9 | 216 | 1200mm*625mm*480mm | |

| 7-tier 2-door | 9 | 252 | 1200mm*625mm*480mm | |

| 8-tier 2-door | 9 | 288 | 1200mm*625mm*480mm | |

Automation System of H-type Layer Chicken Cages

H-type layer cage system is a fully automatic chicken cage system, includes automatic feeding, drinking, manure cleaning, egg collection, environmental control system.

Automatic Egg Collection System

Purpose: Facilitates the efficient and hygienic collection of eggs.

Features: Includes automated conveyor systems, roll-out nest boxes, and sorting mechanisms to streamline egg collection and minimize breakage.

Automatic Feeding System

Purpose: Ensures consistent and timely feeding of poultry.

Features: Incorporates automated feeders, silos, and distribution systems tailored to the specific nutritional needs of chickens at various growth stages.

Automatic Drinking System

Purpose: Ensures continuous and clean water supply for poultry.

Features: Equipped with nipple drinkers, regulators, and filter devices to deliver fresh water efficiently while minimizing spillage and contamination.

Automatic Manure Removing System

Purpose: Facilitates the efficient removal and management of poultry waste.

Features: Includes conveyor belts, scraper systems, and composting solutions to maintain cleanliness and hygiene within the poultry environment.

Automatic Environmental Control System

Purpose: Maintains optimal environmental conditions within the poultry house.

Features: Incorporates ventilation systems, heating solutions, and humidity control mechanisms to create a comfortable and conducive environment for poultry growth and well-being.

Project Cases

📍 Burkina Faso – 30,000 Birds Poultry Farm

📍 50,000 Layers in Zambia– H-Type Chicken Cages

📍 Ghana – 40,000 Layers Poultry Farm

What Our Customers Say

“We used to rely on A-type cages, but after switching to H-type with automation, our farm productivity jumped significantly.”

— Mr. Joseph, Poultry Farm Owner, Uganda

“LIVI’s engineering team helped us design and build our entire poultry house with the H cage system. Everything was on schedule and well-supported.”

— Mr. Kingsley, Farm Manager, Ghana

Why Choose H Type Layer Chicken Cage System

✅ Smart Farm Solution Provider – From cage systems to automatic control and monitoring

✅ Superior Material and Craftsmanship – Long-lasting hot-dip galvanized frames and parts

✅ Engineering Support – Free layout design, installation guidance, and technical training

✅ Global Service Footprint – Over 70 countries served, with on-site service in 30+ countries

✅ Fast Delivery – Optimized production and shipping systems ensure timely delivery

✅ Low Maintenance, High ROI – Ideal solution for long-term commercial egg producers

Our Advantages

13+ Years of Manufacturing Excellence

Global Service in 70+ Countries

Flexible Farm Designs for Every Scale

Chicken Raising Equipment For Sale

Certificate: ISO9001, ISO14001, OHSAS18001, CE, SONCAP, PVOC

Production Lead Time: Depending on the order quantity. Normally about 10 days for 20ft container, 15 days for a 40ft container.

Supply Ability: 10000 Set/Month

Packing Method: Normal export packing. 20ft / 40ft container.

Payment Method: T/T, L/C at sight

Trading Method: EXW, FOB, CFR, CIF

Livi Machinery’s Service

- High quality Chicken cage

- Complete chicken raising equipment

- 365-Day First-Class Service

- Get a Free Quote – Design Within 24 Hours

- 15-45 Days Production

- 60-Day Installation

- Customizable service

- Free chicken house design