H-Type Layer Chicken Cage System for 30,000 Birds Poultry Project in Sierra Leone

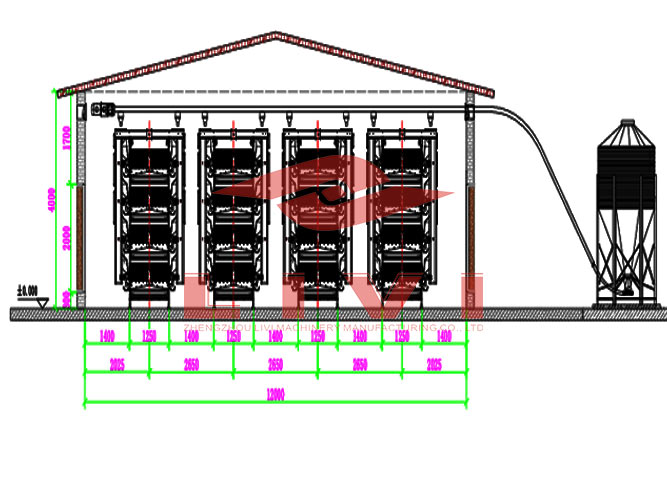

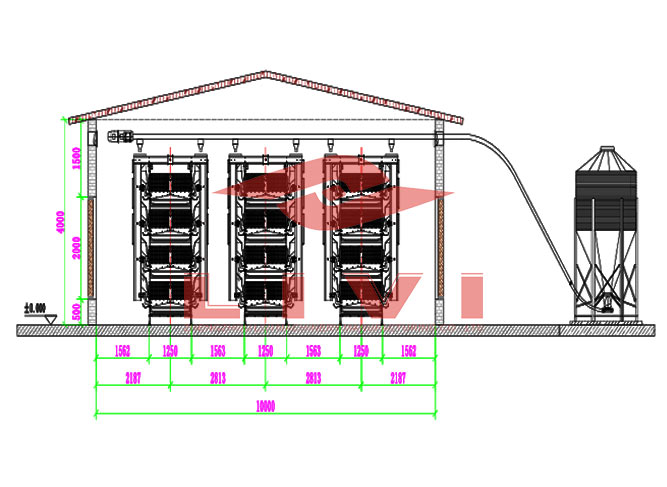

Due to the increasing cost of labor and the limitations of aging poultry housing, this Sierra Leone poultry farm sought to upgrade its outdated facilities to improve operational efficiency and bird welfare. The farm chose LIVI’s H-type layer chicken cage system to replace old equipment and expand capacity to 30,000 layers within a single poultry house arranged in 3 rows and 4 tiers.

The fully automated system facilitates precise feeding, efficient manure removal, reliable egg collection, and a clean water supply, helping the farm reduce labor costs, improve biosecurity, and increase overall productivity under the local warm and humid climate conditions.

Project Overview

Location: Sierra Leone

Total Layers: 30,000 birds

Cage Model: H-type 4-tier layer cages

Cage Layout: Single poultry house with 3 rows

Number of Cage Sets: 210 sets

Birds per Set: 144 birds

Total Capacity: 30,240 birds

Automation Included: Automatic feeding, egg collection, manure cleaning, and nipple drinking system

Using 210 sets of H-type 4-tier cages, each housing 144 birds, the farm achieves a total installed capacity of 30,240 layers—perfectly aligned with the target of 30,000 hens while allowing for reserve stock and efficient rotation.

Equipment Supplied

| Equipment Lists | Quantity | Description |

| H-Type 4-Tier Layer Cage Sets | 210 sets | 144 birds per set, total 30,240 birds |

| Automatic Feeding Machine | 5 sets | Feeds all rows uniformly |

| Automatic Manure Cleaning System | 5 sets | One system per cage row |

| Egg Collection Machines | 5 sets | Fully automatic egg collection per row |

| Nipple Drinking System with Water pressure regulator | Full set | Stable, clean water supply for all birds |

| Climate Control System | Customized | Fans, air inlets, and side curtains for airflow |

Why Choose H-Type Layer Cages in Sierra Leone?

Poultry farms in Sierra Leone face challenges such as limited labor availability, high humidity, and the need to meet rising consumer demand for eggs. The H-type 4-tier cage system offers a practical solution, enabling high-density stocking in a compact footprint while maintaining excellent ventilation.

With full automation, the farm reduces daily labor costs and improves overall egg quality through cleaner handling and reduced breakage. Durable hot-dip galvanized materials ensure the system performs well in tropical environments with minimal maintenance.

Client Feedback

“This was our first time using a large-scale cage system. LIVI’s team gave us the confidence to move forward. The equipment is solid, easy to manage, and the automated egg collection and feeding are a big help. We’ve seen clean operations and consistent production from the start.”

— Poultry Farm Manager, Sierra Leone

Key Benefits of the H-Type Layer Chicken Cage System

- Space-saving layout with 3 rows and 4 tiers

- Hot-dip galvanized steel for long-lasting performance

- Full automation improves efficiency and reduces labor

- Clean egg handling and reduced breakage

- Better manure management improves hygiene

- Suitable for humid tropical climates

Grow Your Poultry Business with LIVI

LIVI Machinery offers complete cage solutions tailored to your farm’s size, environment, and goals. Our H-type layer chicken cage systems are trusted by farmers in over 70 countries for their durability, performance, and easy operation.

Contact Us

Email: [email protected]

WhatsApp/WeChat: +86 155 3717 9350

Website: www.livimachinery.com