H Type Pullet Chicken Cage System

Breeds: baby chicks

Rearing Quantity / House: 20,000-50,000 birds

Service life: 15-20 years

Warranty period: 3 years

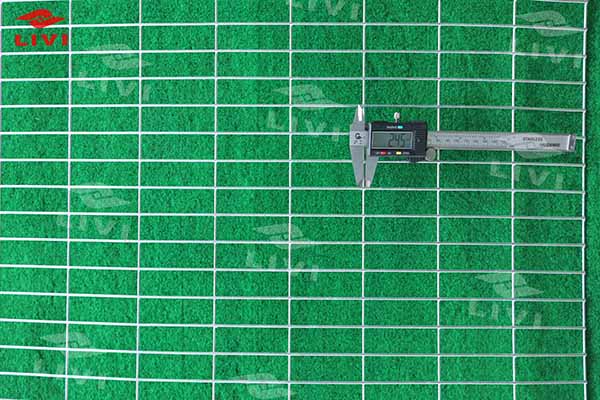

Material: International Q235 steel, hot-dip galvanized.

Certificate: ISO9001, CE, SONCAP, PVOC

Product Introduction

The H Type Pullet Chicken Cage System is a scientifically designed rearing solution for commercial layer pullets from 1 day old to 16 weeks. This system ensures uniform growth, low mortality, and smooth transition to layer cages by providing optimal feeding, drinking, ventilation, and space conditions in a multi-tier, high-density structure.

Constructed with durable hot-dip galvanized steel and equipped with automated systems, the H type pullet cage system is ideal for intensive poultry farms aiming to raise healthy, strong young layers.

🐣 Applicable For:

- Farms with automatic environmental control systems

- Suitable for: Layer pullet chicks (0–16 weeks)

- Large-scale commercial egg farms: 20,000–100,000 birds per farm

- Material: Hot-dip galvanized steel, corrosion-resistant for up to 15+ years

Specifications of H Type Pullet Chicken Cage System

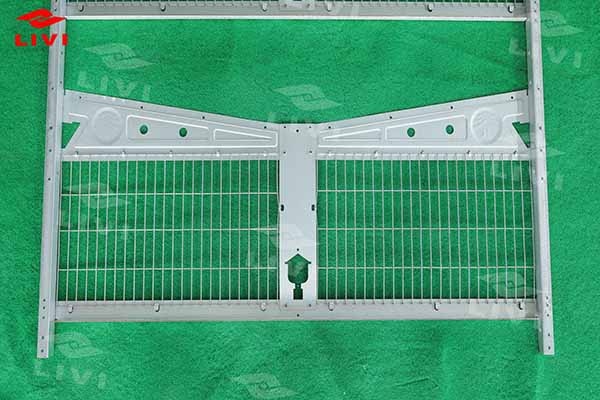

H-type chicken cage is composed of cage frame and cage net.

Solid construction

Hierarchical design

High quality metal material

Grid design

chicken drinking line

| Battery Chicken Cage System for Pullets Specification | |||||

| Type | Weight | Model | Birds Qty/Door | Birds Qty/Unit | Specification |

| H-Type Pullet Cage | 54KG | 3-Tier 2-Door | 24-25 pcs | 144-150 pcs | 1200mm*625mm*430mm |

| 72KG | 4-Tier 2-Door | 24-25 pcs | 192-200 pcs | 1200mm*625mm*430mm | |

One-on-one customized solutions and quotations based on your breeding volume or chicken house size.

Full Automation System of H Type Pullet Chicken Cage

H Type Pullet Chicken Cage System is fully compatible with advanced automation technology, allowing poultry farmers to raise pullets with less labor and more precision. Includes:

Automatic Feeding System

Purpose: Ensures consistent and timely feeding of poultry.

Features: Incorporates automated feeders, silos, and distribution systems tailored to the specific nutritional needs of chickens at various growth stages.

Belt Manure Removal System

Purpose: Facilitates the efficient removal and management of poultry waste.

Features: Includes conveyor belts, scraper systems, and composting solutions to maintain cleanliness and hygiene within the poultry environment.

Central Climate Control (Optional)

Purpose: Maintains optimal environmental conditions within the poultry house.

Features: Incorporates ventilation systems, heating solutions, and humidity control mechanisms to create a comfortable and conducive environment for poultry growth and well-being.

Project Cases

📍 Burkina Faso – 30,000 Birds Poultry Farm

📍 Zambia – 50,000 birds Poultry Farm

📍 Ghana – 40,000 Birds Poultry Farm

⭐ “We installed LIVI’s H-type chicken cages for 50,000 hens in Nigeria. The system runs smoothly and the egg output improved significantly.”

— Mr. Olusegun, Poultry Farm Owner, Nigeria

⭐ “The brooder cage system from LIVI saved us a lot of labor and space. The automatic feeding and manure belt system is very efficient.”

— Faisal A., Farm Manager, Saudi Arabia

Our Advantages

13+ Years of Manufacturing Excellence

Global Service in 70+ Countries

Flexible Farm Designs for Every Scale

Chicken Raising Equipment For Sale

Certificate: ISO9001, ISO14001, OHSAS18001, CE, SONCAP, PVOC

Production Lead Time: Depending on the order quantity. Normally about 10 days for 20ft container, 15 days for a 40ft container.

Supply Ability: 10000 Set/Month

Packing Method: Normal export packing. 20ft / 40ft container.

Payment Method: T/T, L/C at sight

Trading Method: EXW, FOB, CFR, CIF

Livi Machinery’s Service

- High quality Chicken cage

- Complete chicken raising equipment

- 365-Day First-Class Service

- Get a Free Quote – Design Within 24 Hours

- 15-45 Days Production

- 60-Day Installation

- Customizable service

- Free chicken house design