Hot-dip Galvanized A-Type Chicken Cages for 20,000 Layers Poultry Farm in Sudan

Project Overview

In March 2024, Livi Machinery delivered a complete set of Hot-dip Galvanized A-Type Chicken Cages to a large-scale egg production farm in Sudan. With the aim of raising over 20,000 laying hens, the client required a durable, efficient, and easy-to-maintain cage system suitable for a hot, dry climate. The project featured a well-ventilated open-sided house and automated equipment to support daily operations.

Project Details

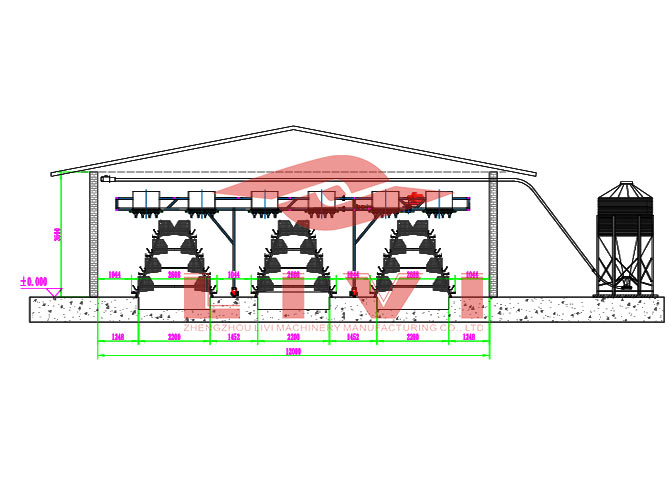

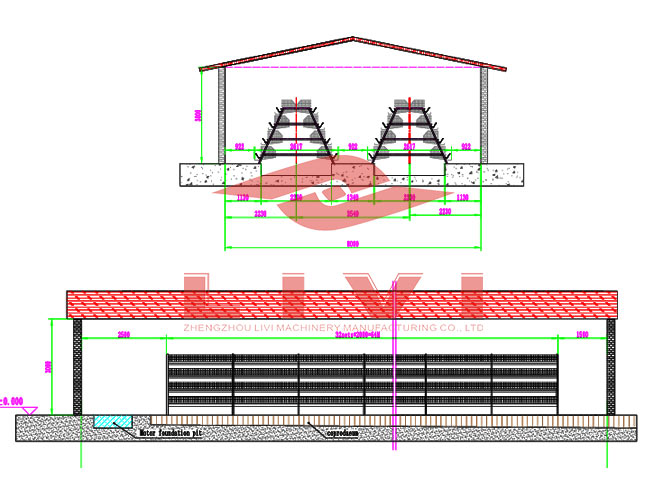

To match the production scale and land availability, the poultry house was built to accommodate high stocking density with smooth maintenance access:

- Cage Model: A-Type, 4-tier, 5-door

- Cage Dimensions: 1950mm × 450mm × 410mm

- Birds per cage set: 160 layers

- Chicken Shed Size: 70m × 15m × 3.5m

- Layout: 4 rows × 32 sets = 128 sets total

- Total Capacity: 20,480 laying hens

This layout offered an ideal balance of space utilization, ventilation, and ease of feeding and cleaning within the shed.

Equipment Supplied

To meet operational needs and local conditions, Livi Machinery provided:

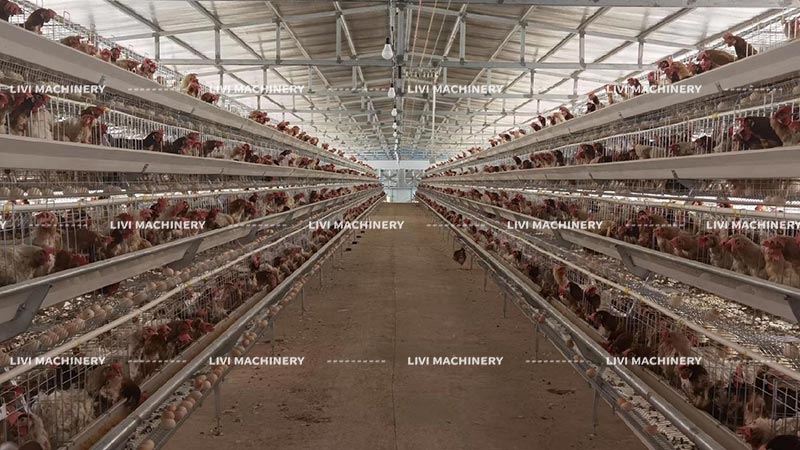

- ✅ 128 sets of Hot-dip Galvanized A-Type Chicken Cages

- ✅ Belt-type manure removal system (1 set for 4 rows)

- ✅ Gantry-type automatic feeding machine (1 set for the house)

- ✅ Nipple drinking system with water tanks

- ✅ Automatic Egg Collecting System

The full hot-dip galvanization ensures strong rust resistance and long service life, particularly under the arid conditions of Sudan.

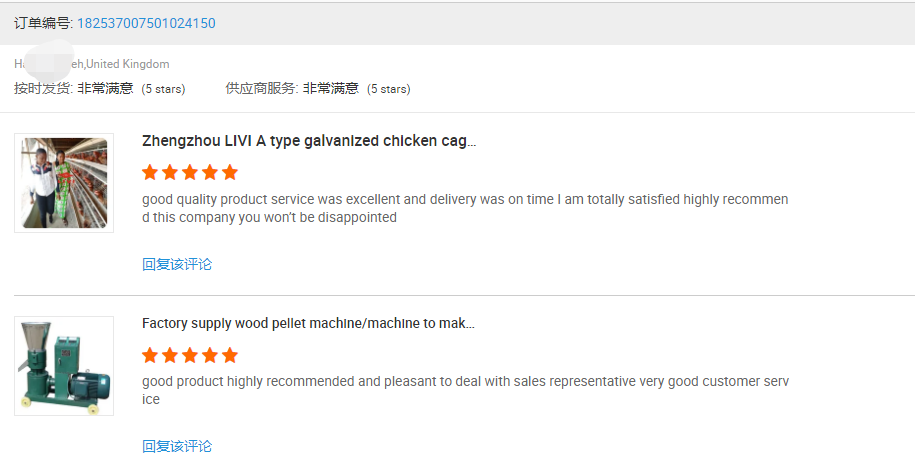

Customer Feedback

The Sudanese client was highly satisfied with:

- The quality and anti-corrosion performance of the cages

- The smooth operation of scraper cleaning and gantry feeding

- The accurate layout design and remote guidance from Livi

- The fast delivery and professional communication throughout the process

Why Choose Livi’s Hot-dip Galvanized A-Type Chicken Cages?

Livi’s Hot-dip Galvanized A-Type Cages are built for long-term use, with anti-rust coating and strong structural integrity, ideal for farms in Africa and other tropical regions. Combined with reliable semi-automation, this system ensures:

- Higher egg production efficiency

- Cleaner shed environment

- Lower daily labor demand

- Strong adaptability to open or closed chicken houses