Implementing an Automatic Chicken Cage System for 50,000 Chickens in Zambia

Introduction

The poultry industry in Zambia is rapidly growing, and with the increased demand for chicken meat, efficient and automated systems are becoming more crucial. For large-scale poultry farms, an automatic chicken cage system can greatly enhance productivity and reduce labor costs. In this article, we will explore the benefits and considerations of implementing an automatic chicken cage system for a 50,000 chicken operation in Zambia.

Why an Automatic Chicken Cage System?

An automatic chicken cage system offers several advantages over traditional manual systems:

– Efficiency: Automated systems can handle tasks such as feeding, watering, and monitoring the health of the chickens, reducing the need for manual labor.

– Sanitation: Regular cleaning of the cages helps prevent the spread of diseases, which is essential in a high-density environment like a 50,000 chicken farm.

– Cost Reduction: Although the initial investment might be high, over time, the savings from reduced labor and increased productivity can offset the costs.

System Components and Features

For a 50,000 chicken farm in Zambia, the following components are typically included in an automatic chicken cage system:

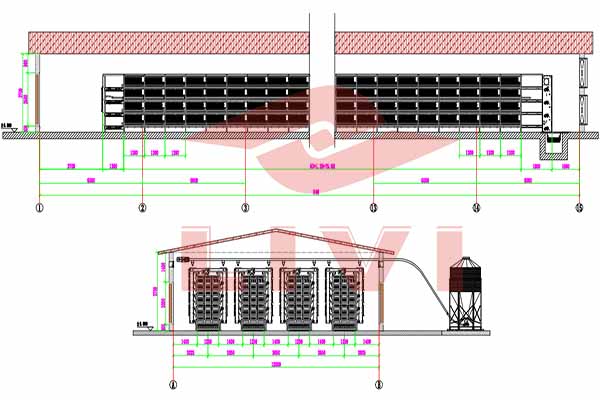

– Feeding System: Automated feeders can dispense feed according to a predetermined schedule, ensuring that all chickens receive balanced nutrition.

– Watering System: Self-drinking systems ensure that chickens have access to clean water at all times.

– Monitoring System: Sensors can track chicken health, weight gain, and other key metrics.

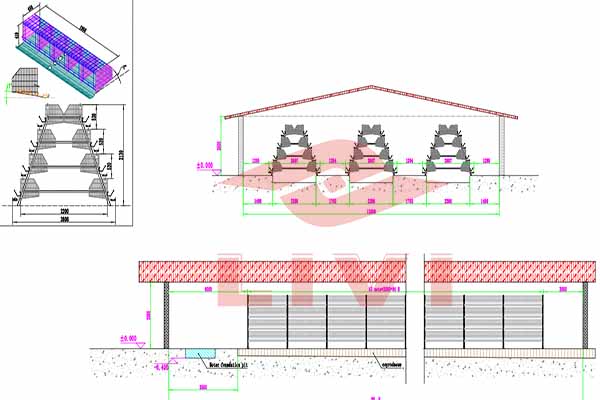

– Ventilation System: Proper ventilation is crucial for maintaining a healthy environment, especially in high-density settings.

Case Study: Success in Zambia

A local farm in Zambia successfully implemented an automatic chicken cage system for their 50,000 chicken operation. The results were impressive:

– Productivity: The farm saw a 20% increase in productivity due to the automated system.

– Health: The incidence of disease decreased by 30%.

– Cost: The labor costs were reduced by 50%.

Considerations for Implementation

When implementing an automatic chicken cage system, consider the following factors:

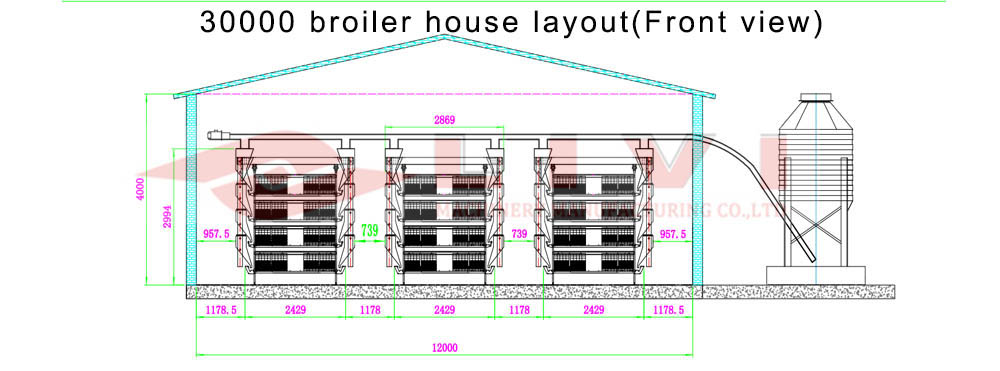

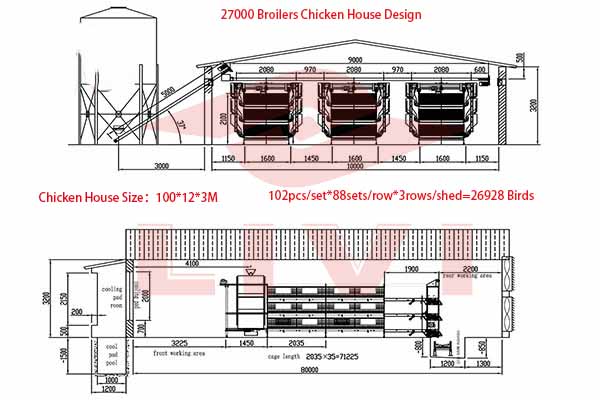

– Space: Ensure that the farm has enough space to accommodate the system.

– Power Supply: A reliable power source is essential for the operation of the automated systems.

– Training: Staff training is crucial for the successful operation and maintenance of the system.

Conclusion

Implementing an automatic chicken cage system for a 50,000 chicken farm in Zambia can revolutionize the poultry industry, offering efficiency, cost savings, and improved health outcomes for the chickens. For those considering such an investment, it is essential to carefully plan and execute the project.

For more information and to discuss your specific needs, please leave a comment below or contact us directly for a free, tailored chicken farming design and equipment quote.